Heat pump integrated fuel cell automobile heat management system with waste heat utilization function

A thermal management system, fuel cell technology, applied in fuel cells, battery/fuel cell control devices, electric vehicles, etc. The effect of reducing thermal efficiency, improving low-temperature driving range, and improving the range of use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

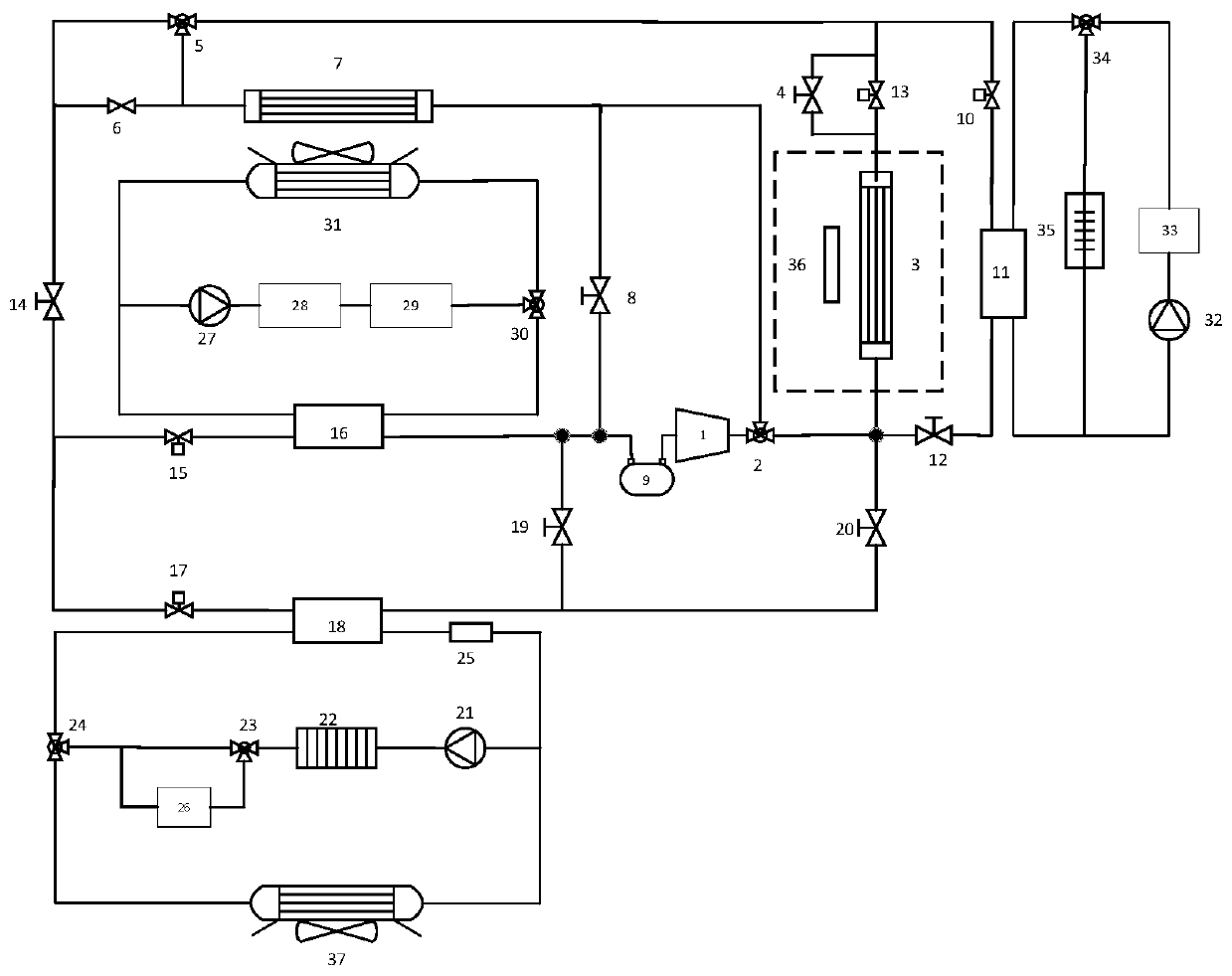

[0067] Embodiment 1, the direct cold start function of the fuel cell 22 heated by the heat pump cycle:

[0068] Such as figure 2 As shown, in the heat pump circulation circuit, adjust the No. 1 reversing valve 2 to connect to the evaporator 3, open the No. 2 shut-off valve 20, No. 3 shut-off valve 8, and No. 6 shut-off valve 14, and keep No. 1 shut-off valve 19, No. No. 12 shut-off valve and No. 5 shut-off valve 4 are closed, No. 1 electronic expansion valve 17 is fully open, No. 2 electronic expansion valve 15, No. 3 electronic expansion valve 13, and No. 4 electronic expansion valve 10 are in the closed state without power supply; Connected compressor 1, No. 1 reversing valve 2, No. 2 stop valve 20, No. 1 plate heat exchanger 18, No. 1 electronic expansion valve 17, No. 6 stop valve 14, throttling pipe 6, condenser 7, and three No. shut-off valve 8 and dryer 9 form the direct cold start cycle of fuel cell 22.

[0069] The refrigerant passes through the compressor 1 to for...

Embodiment 2

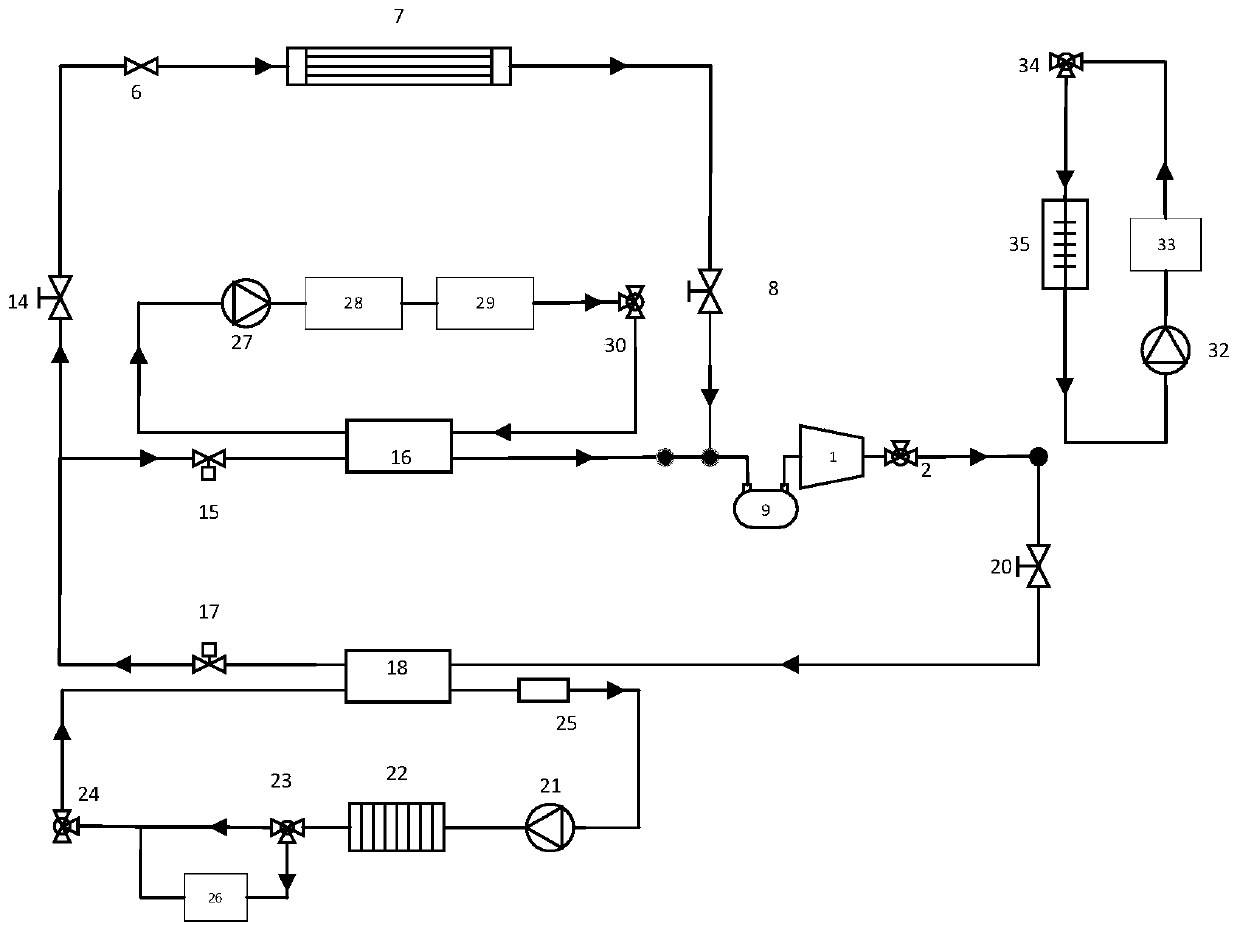

[0073] Embodiment 2 provides the function of the heat pump to recycle waste heat from the motor cycle or the fuel cell 22 cycle to heat the passenger compartment:

[0074] Such as image 3 As shown, in the heat pump circulation circuit, the flow direction of No. 1 reversing valve 2 is adjusted so that it is connected to the evaporator 3, No. 1 shut-off valve 19, No. 2 shut-off valve 20, No. 4 shut-off valve 12, and No. 6 shut-off valve 14 are closed. No. 3 shut-off valve 8 and No. 5 shut-off valve 4 are opened, and No. 2 reversing valve 5 is adjusted to connect to No. 6 shut-off valve 14; compressor 1, No. 1 reversing valve 2, evaporator 3, and No. 5 are connected sequentially. Stop valve 4, No. 2 reversing valve 5, throttling pipe 6, condenser 7, No. 3 stop valve 8, and dryer 9 form an ambient heat source heat pump cycle.

[0075] The refrigerant passes through the compressor 1 to form a high-temperature, high-pressure refrigerant, and then enters the evaporator 3 through th...

Embodiment 3

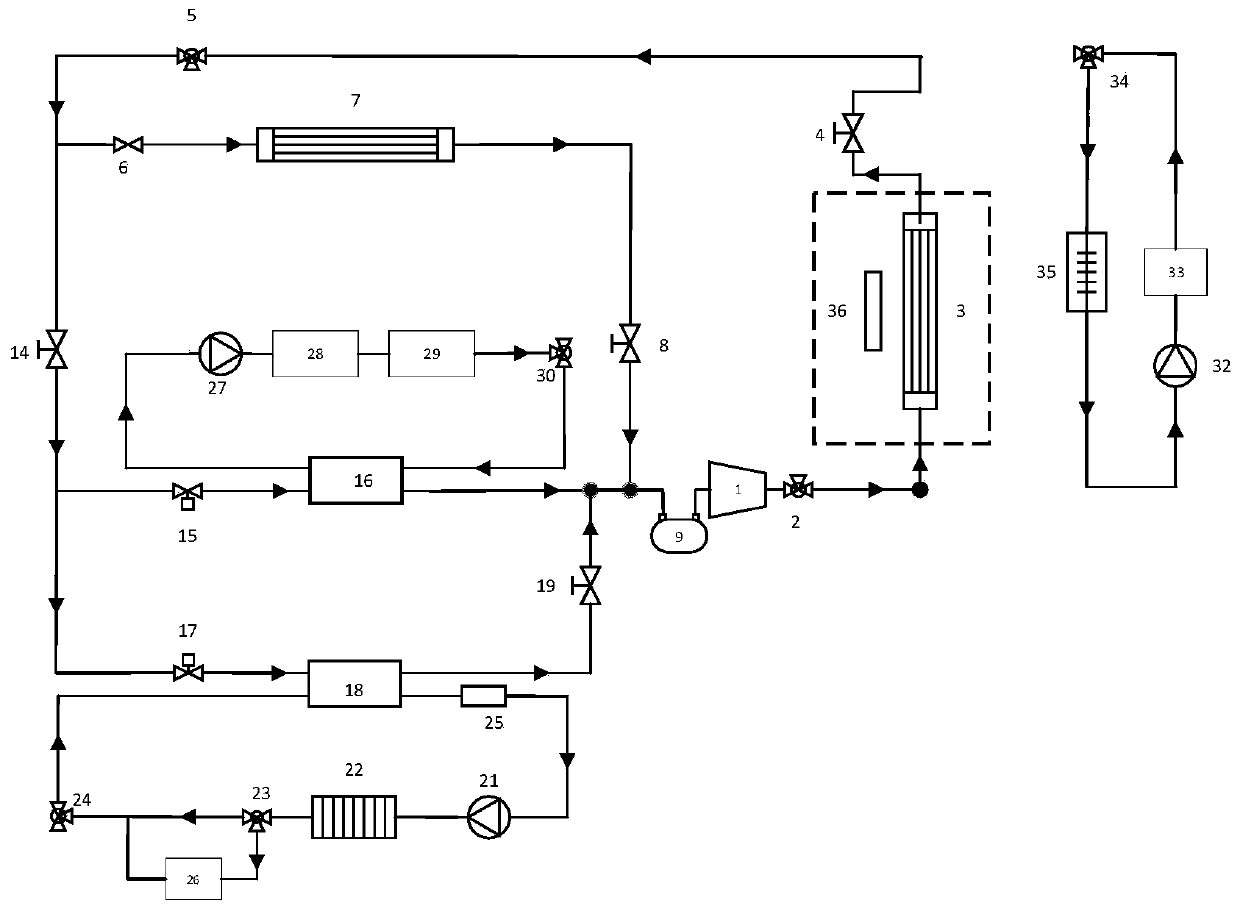

[0079] Embodiment 3, the function of heating the passenger compartment by only using the motor to circulate waste heat:

[0080] If the ambient temperature is low and the efficiency of heating the passenger compartment with an ambient heat source is very low, then close the No. 3 shut-off valve 8, and all the refrigerant passing through the No. 2 reversing valve 5 will pass through No. 6 shut-off valve 14 and No. 2 electronic expansion valve 15 to enter the No. 1 valve. The two-plate heat exchanger 16 forms a motor single heat source heat pump cycle.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com