Detonating tube production line and production method

A detonator and production line technology, which is applied in fuse manufacturing and other directions, can solve problems such as low production efficiency, unstable detonator performance, and impact on detonator quality, and achieve stable quality, easy detonation speed, and stable detonation speed.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

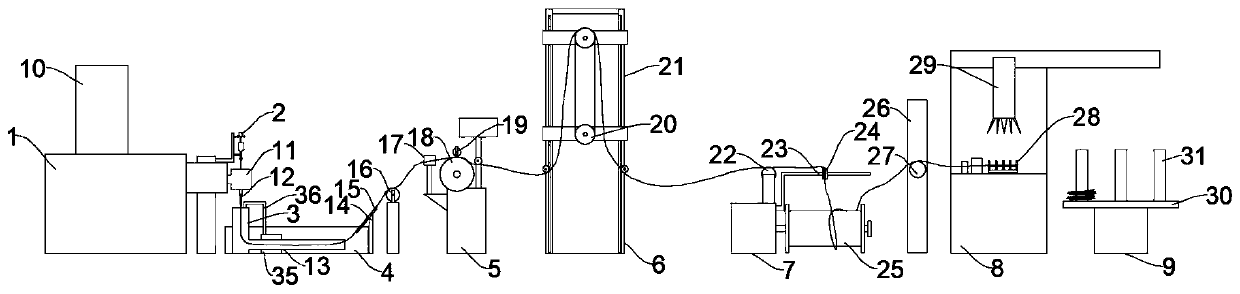

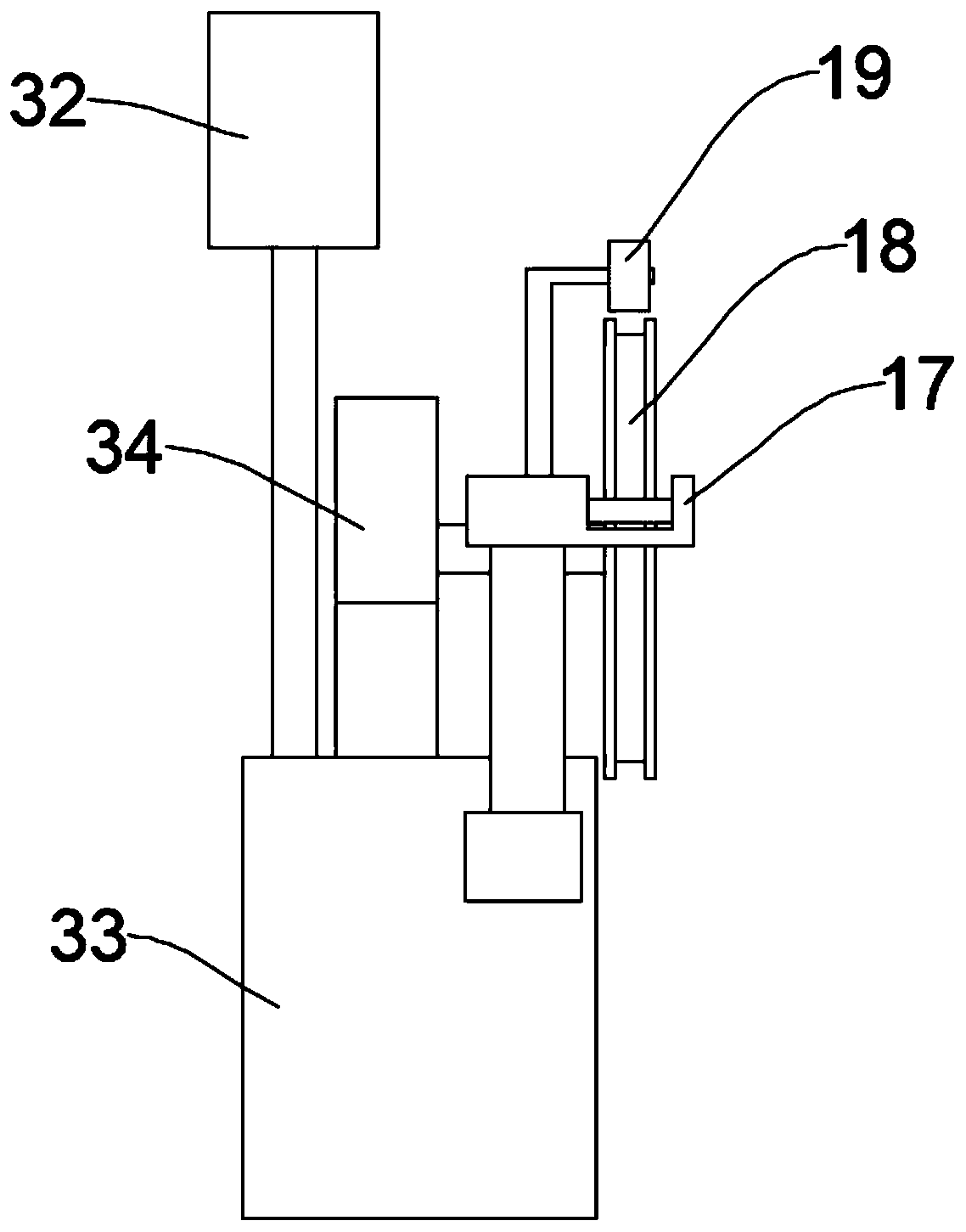

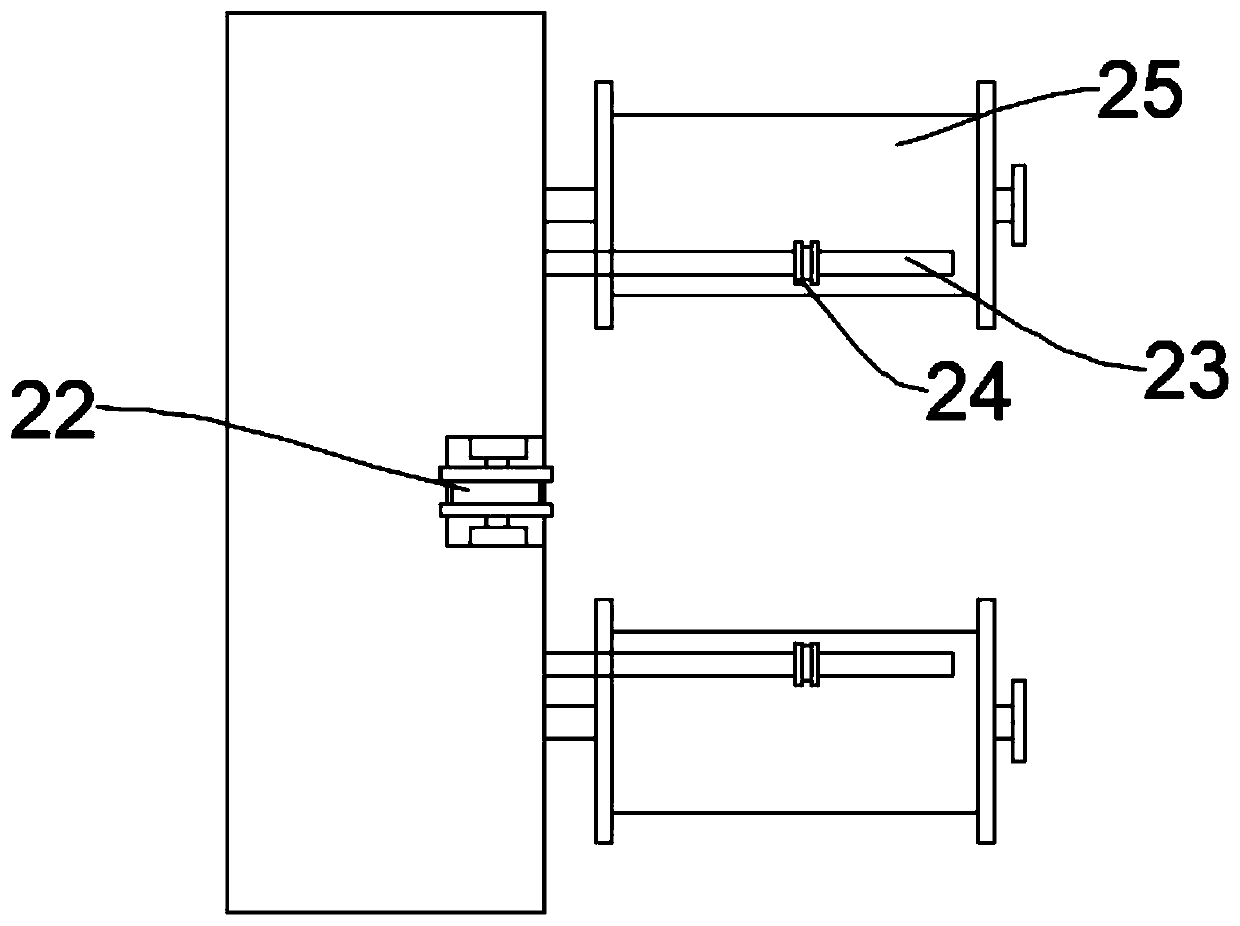

[0040] Such as Figure 1-Figure 4 As shown, this embodiment provides a nonel production line, including an extrusion blow molding machine 1, a dosing device 2, a cooling cylinder 3, a pool 4, a tractor 5, a buffer machine 6, a winder 7, and a handle machine 8 and the material receiver 9, the dosing device 2 is arranged above the output end of the extrusion blow molding machine 1, wherein the dosing device 2 is used to add explosives, and the dosing end of the dosing device 2 is placed in the extrusion blow molding In the output end of the machine 1, the extrusion blow molding machine 1 extrudes the melted plastic raw material, and then blows it into a plastic tube, and then adds the explosive to the plastic tube by the dosing device 2, wherein the explosive is powdered The shape is attached to the inner wall of the nonel tube, wherein the plastic tube moves under the action of the tractor 5, so that the plastic raw material is continuously extruded and blown into a plastic tub...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com