A kind of preparation method of ultrasonically modified composite gelatin film

A technology of ultrasonic modification and gelatin film, applied in the field of gelatin film, can solve the problem of only controlling the amount of oily components added, and achieve the effects of good mechanical properties, high product quality and low film thickness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

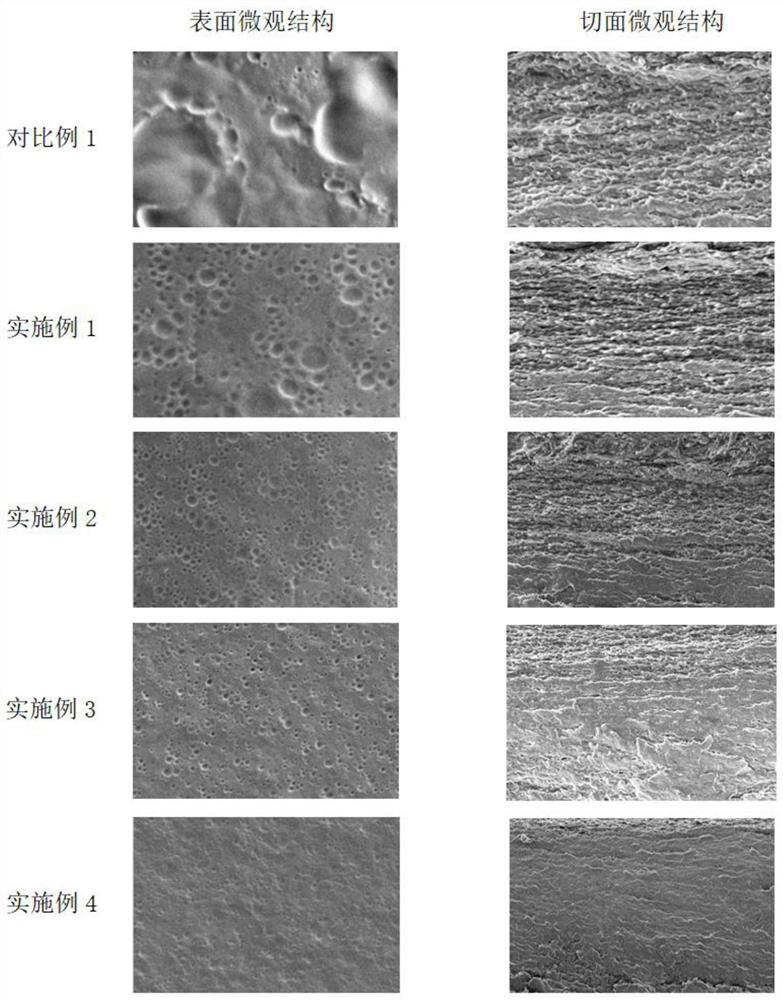

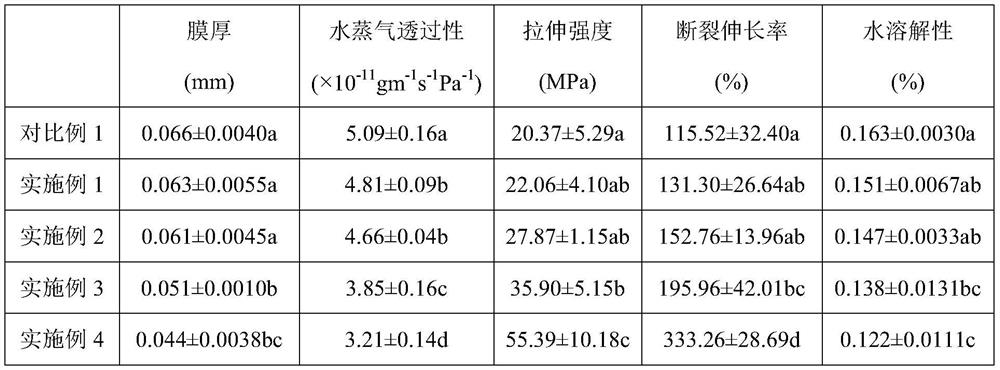

Examples

preparation example Construction

[0029] A preparation method for ultrasonically modified composite gelatin film, comprising the steps of:

[0030] (1) The following materials are selected in parts by weight: 8% gelatin, 1% glycerin, 4% soybean oil, 0.8% Tween, and the rest are deionized water, 100% in total.

[0031] (2) Mix gelatin and water in parts by weight, dissolve in a 60°C aqueous solution for 90 minutes, and keep stirring until the gelatin is completely dissolved.

[0032] (3) cooling the gelatin solution in step (2) to room temperature, adding the glycerin solution in parts by weight, and mixing evenly to obtain a gelatin-glycerol aqueous solution;

[0033] (4) mixing soybean oil and Tween 80 in parts by weight, and fully shaking with an oscillator to obtain an oily solution;

[0034] (5) The aqueous solution of step (3) is mixed with the oily solution of step (4), and homogenized for 3 minutes under the condition of 13000 rpm with a homogenizer to obtain a composite gelatin film liquid;

[0035] ...

Embodiment 1

[0044] (1) The following materials are selected in parts by weight: 8% gelatin, 1% glycerin, 4% soybean oil, 0.8% Tween, and the rest are deionized water, 100% in total.

[0045] (2) Mix gelatin and water in parts by weight, dissolve in a 60°C aqueous solution for 90 minutes, and keep stirring until the gelatin is completely dissolved.

[0046](3) cooling the aqueous gelatin solution in step (2) to room temperature, adding glycerin solution in parts by weight, and mixing uniformly to obtain a gelatin-glycerol aqueous solution;

[0047] (4) mixing soybean oil and Tween 80 in parts by weight, and fully shaking with an oscillator to obtain an oily solution;

[0048] (5) The aqueous solution of step (3) is mixed with the oily solution of step (4), and homogenized for 3 minutes under the condition of 13000 rpm with a homogenizer to obtain a composite gelatin film liquid;

[0049] (6) Ultrasonic the gelatin emulsion of step (5) for 3 minutes under the condition of 210w to obtain th...

Embodiment 2

[0053] (1) The following materials are selected in parts by weight: 8% gelatin, 1% glycerin, 4% soybean oil, 0.8% Tween, and the rest are deionized water, 100% in total.

[0054] (2) Mix gelatin and water in parts by weight, dissolve in a 60°C aqueous solution for 90 minutes, and keep stirring until the gelatin is completely dissolved.

[0055] (3) cooling the aqueous gelatin solution in step (2) to room temperature, adding glycerin solution in parts by weight, and mixing uniformly to obtain a gelatin-glycerol aqueous solution;

[0056] (4) mixing soybean oil and Tween 80 in parts by weight, and fully shaking with an oscillator to obtain an oily solution;

[0057] (5) The aqueous solution of step (3) is mixed with the oily solution of step 4, and homogenized for 3 minutes under the condition of 13000 rpm with a homogenizer to obtain a composite gelatin emulsion;

[0058] (6) Ultrasonic the gelatin emulsion of step (5) for 6 min under the condition of 210w to obtain the film l...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com