Preparation method of antioxidant for nitrile rubber

A technology of nitrile rubber and antioxidant, applied in the field of preparation of antioxidant for environment-friendly nitrile rubber

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

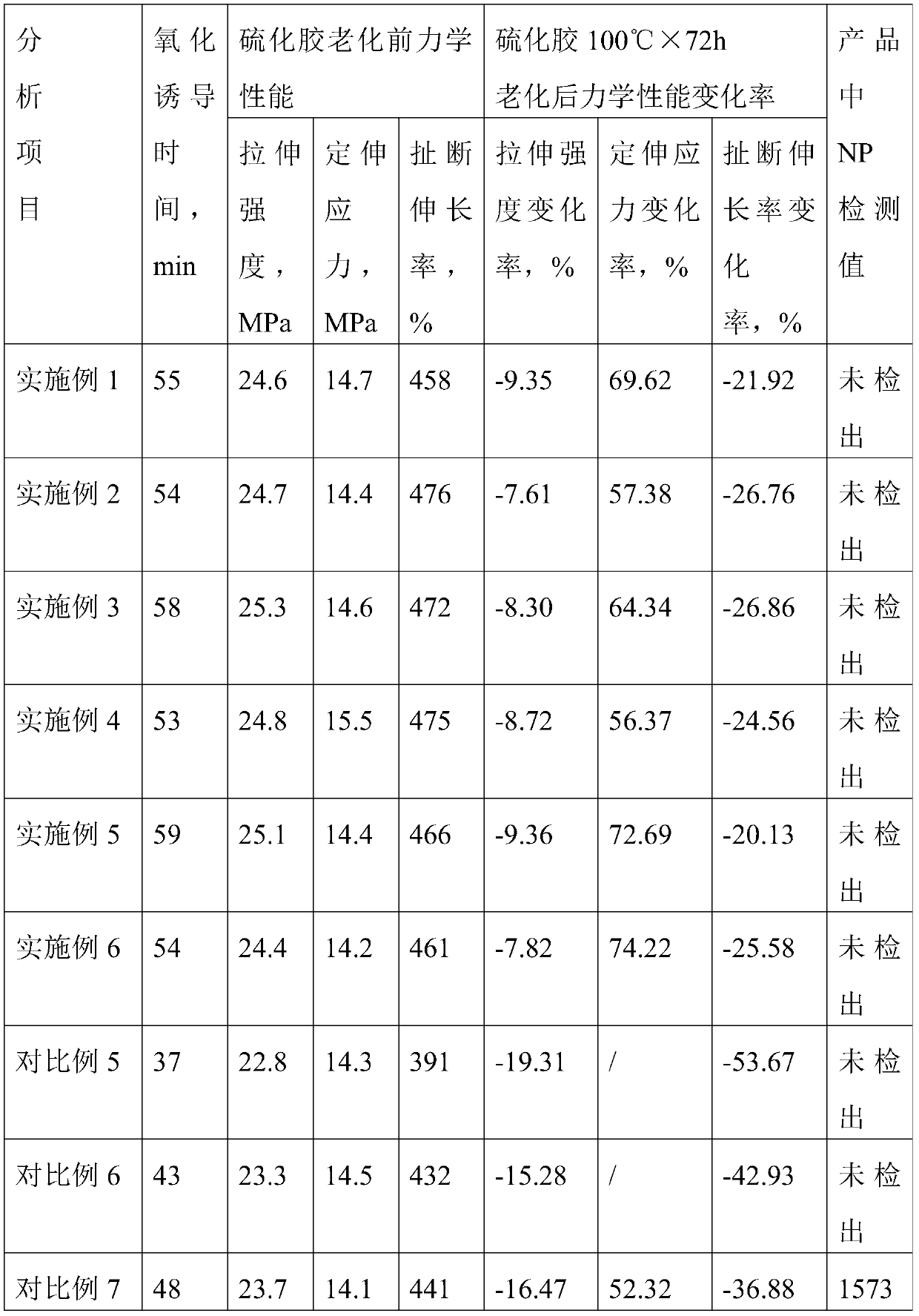

Examples

Embodiment 1

[0035] Accurately weigh 60g of carbonyl-4,4-diisoidene-fatty alcohol-phosphate chelate, 20g of β-(3,5-di-tert-butyl-4-hydroxyphenyl)propionic acid octadecyl ester, 40g 4,4'-bis(phenylisopropyl)diphenylamine, firstly add carbonyl-4,4-diisopropylidene-fatty alcohol-phosphate chelate into the beaker, stir and heat to 85℃, then add β -(3,5-Di-tert-butyl-4-hydroxyphenyl) octadecyl propionate and 40g 4,4'-bis(phenylisopropyl)diphenylamine, keep stirring until the solid antioxidant is completely melted , add 40g potassium oleate soap liquid, 10g dodecyl polyglycoside in turn, emulsification for 5 minutes under high-speed stirring at 15000 r / min, add 30g deionized water, continue stirring and emulsification for 5 minutes, cool down to 25 ℃ and let stand Storage, preparation to the antioxidant product of the present invention.

Embodiment 2

[0037] Accurately weigh 80g of carbonyl-4,4-diisoidene-fatty alcohol-phosphate chelate, 10g of β-(3,5-di-tert-butyl-4-hydroxyphenyl)propionic acid octadecyl ester, 30g butyl octylated diphenylamine, firstly, carbonyl-4,4-diisoidene-fatty alcohol-phosphate chelate will be added to the beaker, heated to 88°C with stirring, and then add β-(3,5-diphenylamine) tert-butyl-4-hydroxyphenyl) octadecyl propionate and butyl octyl diphenylamine, keep stirring until the solid antioxidant melts completely, add 36g potassium oleate soap solution, 4g octyl polyglycoside, Emulsify for 5 minutes under high-speed stirring at a rotational speed of 15,000 rpm, add 40 g of deionized water, continue stirring and emulsification for 5 minutes, cool down to 28° C. for storage, and prepare the antioxidant product of the present invention.

Embodiment 3

[0039] Accurately weigh 60g of diphenylisodecyl phosphite, 10g of 2,2'-ethylene-bis(4,6-di-tert-butylphenol), 30g of 4,4'-bis(phenylisopropyl) ) diphenylamine, add diphenylisodecyl phosphite into a beaker, stir and heat to 80°C, then add 2,2'-ethylene-bis(4,6-di-tert-butylphenol) and 4,4'-bis(phenylisopropyl)diphenylamine, keep stirring until the solid antioxidant melts completely, add 36g potassium disproportionate rosinate soap solution, 4g dodecyl polyglycoside, rotate at 15000 rpm Emulsify for 5 minutes under high-speed stirring, add 60 g of deionized water, continue to stir and emulsify for 5 minutes, cool down to 30° C. for storage, and prepare the antioxidant product of the present invention.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com