Antibacterial and antiviral toilet lid and preparation method

An anti-virus, toilet cover technology, applied in the field of bathroom, can solve the problem that the antibacterial agent cannot exert the antibacterial effect, accelerate the aging speed of the toilet cover, reduce the service life of the toilet cover, etc., and achieve easy demoulding, low specific surface energy, and improved dispersion. effect of effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] first part:

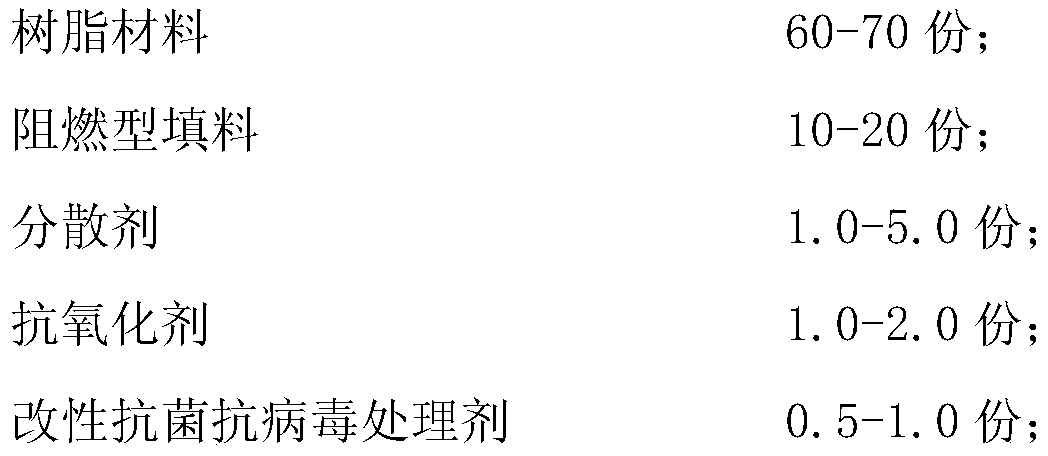

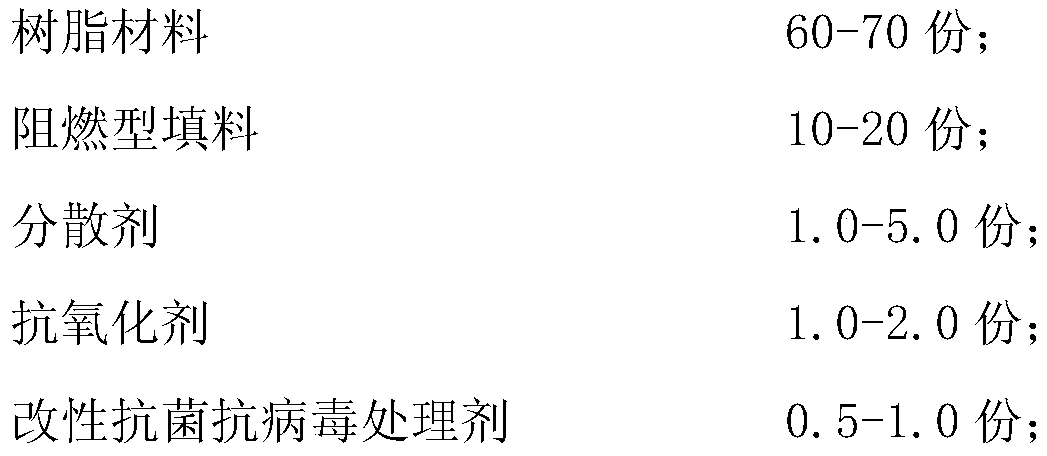

[0032] An antibacterial and antiviral toilet seat is prepared from the following components by weight:

[0033]

[0034] The organosilicon modified photocatalyst is obtained by modifying the inorganic photocatalyst antibacterial agent nano-titanium dioxide with the organosilicon release agent methylphenyl silicone resin,

[0035] The concrete operation method that described organosilicon release agent modifies photocatalyst is as follows:

[0036] Step 1. Vacuum dry the inorganic photocatalyst powder in an oven at 80°C for 4 hours, and cool it for later use;

[0037] Step 2. Prepare an ethanol solution according to 7wt%, and then add the dry-processed inorganic photic mold powder in step 1 to the ethanol solution in an amount of 80wt%, and use a high-speed emulsifier to disperse the mixed solution evenly by shearing at a high speed, and use ultrasonic waves to Oscillate for 30 minutes to make the solution evenly dispersed;

[0038] Step 3. Add silico...

Embodiment 2

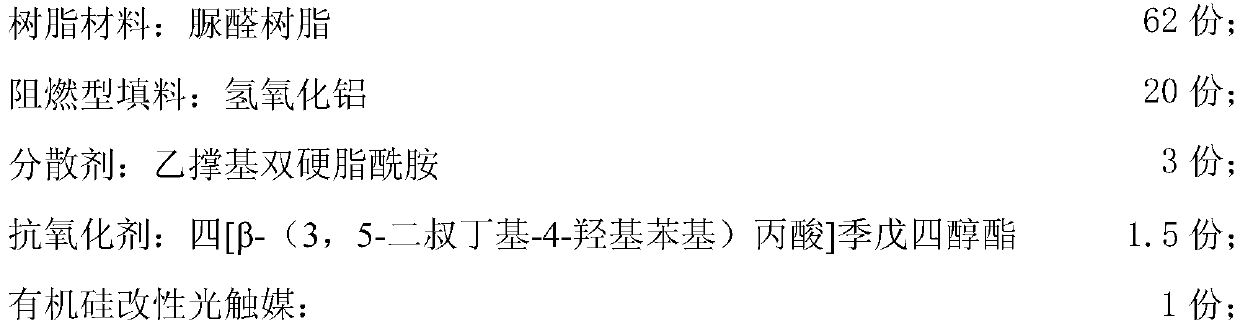

[0045] first part:

[0046] An antibacterial and antiviral toilet seat is prepared from the following components by weight:

[0047]

[0048]

[0049] The organosilicon-modified photocatalyst is obtained by modifying the inorganic photocatalyst antibacterial agent nano-bismuth tungstate with a siloxane compound of an organosilicon release agent,

[0050] The concrete operation method that described organosilicon release agent modifies photocatalyst is as follows:

[0051] Step 1. Vacuum-dry the inorganic photocatalyst powder in an oven at 75°C for 5 hours, and cool it for later use;

[0052] Step 2. Prepare an ethanol solution according to 5wt%, then add the dried inorganic photocatalyst powder in step 1 to the ethanol solution in an amount of 75wt%, use a high-speed emulsifier to disperse the mixed solution evenly, and use an ultrasonic oscillator Shake for 35 minutes to disperse the solution evenly;

[0053] Step 3. Add a silicone release agent siloxane compound to th...

Embodiment 3

[0060] first part:

[0061] An antibacterial and antiviral toilet seat is prepared from the following components by weight:

[0062]

[0063] The organosilicon-modified photocatalyst is obtained by modifying the inorganic photocatalyst antibacterial agent nano-silicon oxide with the organosilicon release agent polyorganosiloxane,

[0064] The concrete operation method that described organosilicon release agent modifies photocatalyst is as follows:

[0065] Step 1. Vacuum dry the inorganic photocatalyst powder in an oven at 65°C for 6 hours, and cool it for later use;

[0066] Step 2. Prepare an ethanol solution according to 6wt%, and then add the dry-processed inorganic photic mold powder in step 1 to the ethanol solution in an amount of 76wt%, and use a high-speed emulsifier to disperse the mixed solution evenly with high-speed shearing, and use ultrasonic waves to Oscillate for 25 minutes to make the solution evenly dispersed;

[0067] Step 3. Add silicone release agen...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com