Anti-fog coating and preparation method thereof

A coating and anti-fog technology, applied in the coating and other directions, can solve the problems of poor light transmittance and wear resistance, poor anti-fog and anti-fog effect, complicated preparation process, etc., to achieve high wear resistance and light transmittance, Excellent water absorption and simple preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

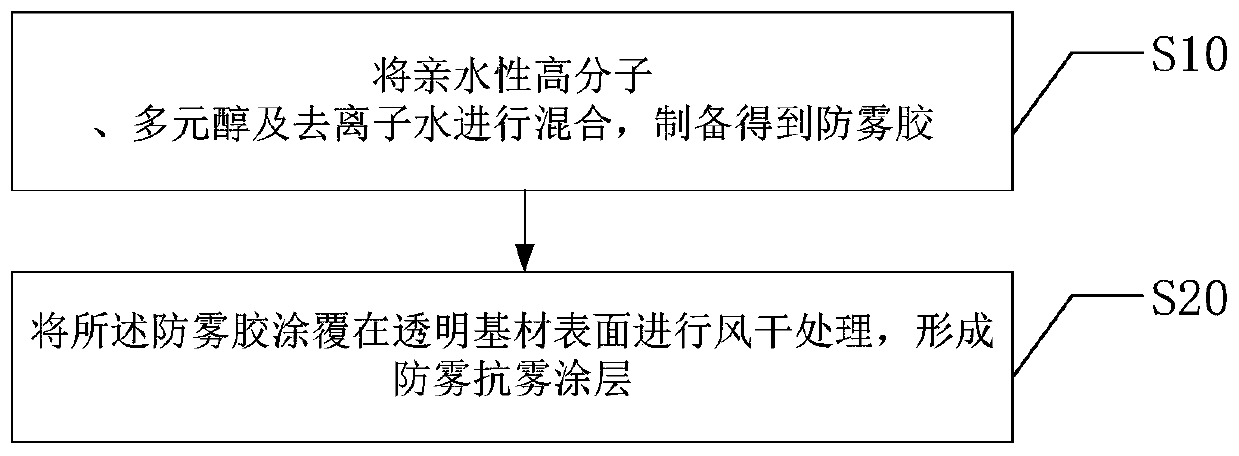

[0023] Aiming at the problems that the existing anti-fog and anti-fog methods are difficult to meet the requirements of light transmittance when used on special medical lenses and polymer films, the preparation process is complicated and the preparation cost is high, the present invention provides an anti-fog and anti-fog coating A preparation method comprising the steps of:

[0024] S10, mixing the hydrophilic polymer, polyol and deionized water to prepare anti-fog glue;

[0025] S20, coating the anti-fog glue on the surface of the transparent substrate for air-drying treatment to form an anti-fog and anti-fog coating.

[0026] In this embodiment, the hydrophilic polymer, polyol and deionized water are firstly mixed to prepare a colorless and transparent anti-fog adhesive. Afterwards, the anti-fog glue is coated on the surface of the transparent substrate, and the excess moisture in the anti-fog glue is removed by air-drying, so that an anti-fog and anti-fog coating can be p...

Embodiment 1

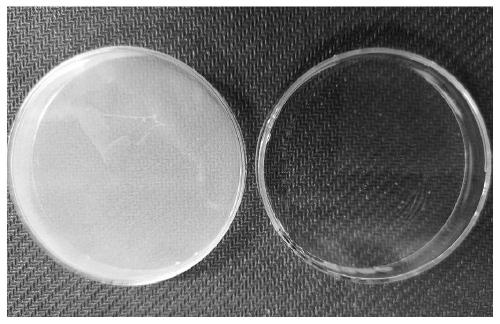

[0035] (1) In parts by weight, 1 part of glycerin AR 99%, 6 parts of polyvinyl alcohol 205 type and 30 parts of deionized water are mixed in a reactor with a temperature of 75° C., and prepared after vacuum defoaming Get anti-fog glue;

[0036] (2) Clean the surface of the transparent substrate to ensure no dust and no moisture residue, introduce a proper amount of anti-fog adhesive after degassing, and use auxiliary tools such as brushes to apply the anti-fog adhesive on the surface of the transparent substrate. After coating, let it stand for 60 minutes, and use the fluid characteristics to evenly spread the anti-fog glue on the surface of the transparent substrate. Thereafter, drying with an infrared dryer, or drying with a blower dryer or a vacuum dryer can prepare a layer of anti-fog and anti-fog coating on the transparent substrate.

Embodiment 2

[0038] (1) In parts by weight, 2 parts of glycerin AR 99%, 6 parts of polyvinyl alcohol 205 type and 30 parts of deionized water are mixed in a reactor at 75° C., and prepared after vacuum defoaming Get anti-fog glue;

[0039] (2) Clean the surface of the transparent substrate to ensure that there is no dust and no moisture residue, introduce an appropriate amount of anti-fog adhesive after defoaming, and use auxiliary tools such as brushes to apply the anti-fog adhesive on the surface of the transparent substrate. After coating, After standing for 60 minutes, the anti-fog glue is evenly spread on the surface of the transparent substrate by using the fluid characteristics, and then dried by an infrared dryer to prepare a layer of anti-fog and anti-fog coating on the transparent substrate.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com