Aluminum-plated steel plate with tensile strength of 1800 MPa, manufacturing method thereof and hot forming part

A technology of tensile strength and manufacturing method, applied in the field of thermoforming parts, can solve problems such as failure to generate phosphating film, and achieve the effects of reducing ineffective consumption, eliminating precipitation, and improving tissue uniformity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0042] The present invention will be described in detail below in conjunction with examples.

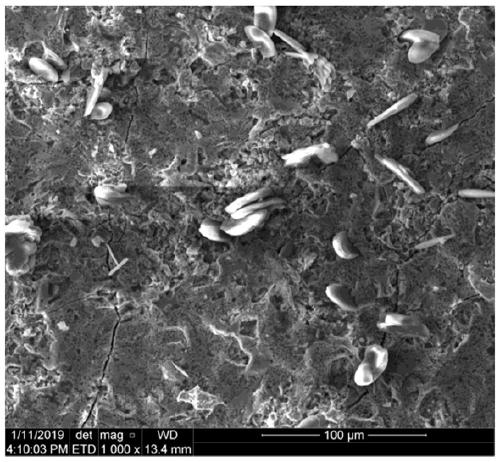

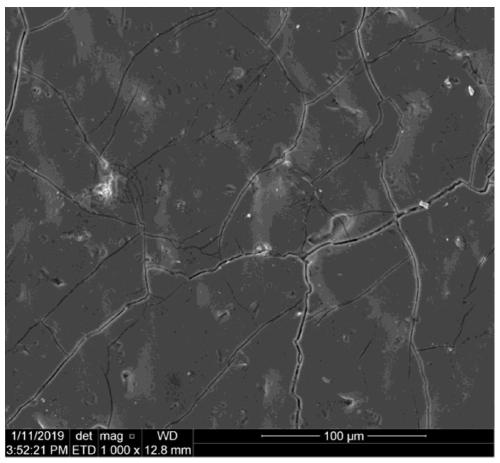

[0043] Through molten iron pretreatment→converter smelting→alloy fine-tuning→refining→continuous casting→hot rolling→pickling→cold rolling→get cold-rolled steel strips with a thickness of 0.8-2.5mm for each composition in Table 1, and then each cold-rolled steel strip After cleaning→continuous annealing→hot-dip plating→coating thickness control→alloying→cooling→oiling and controlling according to the parameters in Table 2-3, aluminum-coated steel sheets were prepared.

[0044] Table 1 is the substrate chemical composition and weight percentage (wt%) in each embodiment and comparative example

[0045] C Si mn P S Al Cr B N Nb+V Ti Example 1 0.35 1.20 2.00 0.005 0.003 0.05 0.25 - ≤0.001 0.080 - Example 2 0.30 1.20 1.80 0.005 0.008 0.06 0.45 - ≤0.001 0.071 - Example 3 0.34 1.00 1.52 0.006 0.010 0.04 0.20 - ≤0.001 0....

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com