Method for optimizing performance of gas-sensitive material

A technology of gas-sensing materials and optimization methods, which is applied in the field of sensing materials, can solve the problems of high consumption of manpower and material resources, and long research and development cycle of new materials, so as to reduce the expenditure of manpower and material resources, improve the efficiency of research and development, and reduce the effect of experimental manpower

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

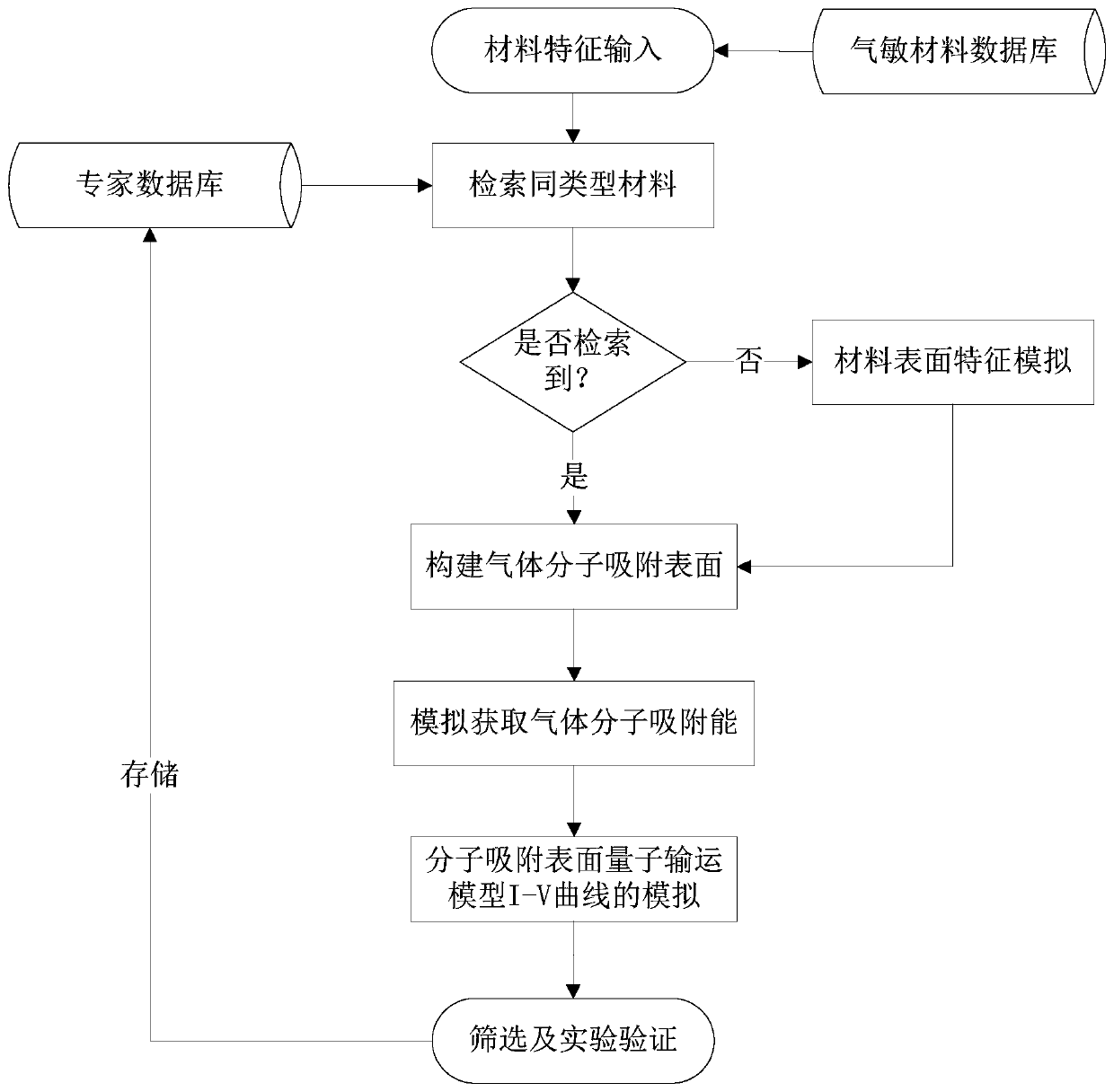

[0033] single layer WS 2 As an example, a single-layer WS 2 The method for optimizing the performance of gas-sensitive materials includes the following steps:

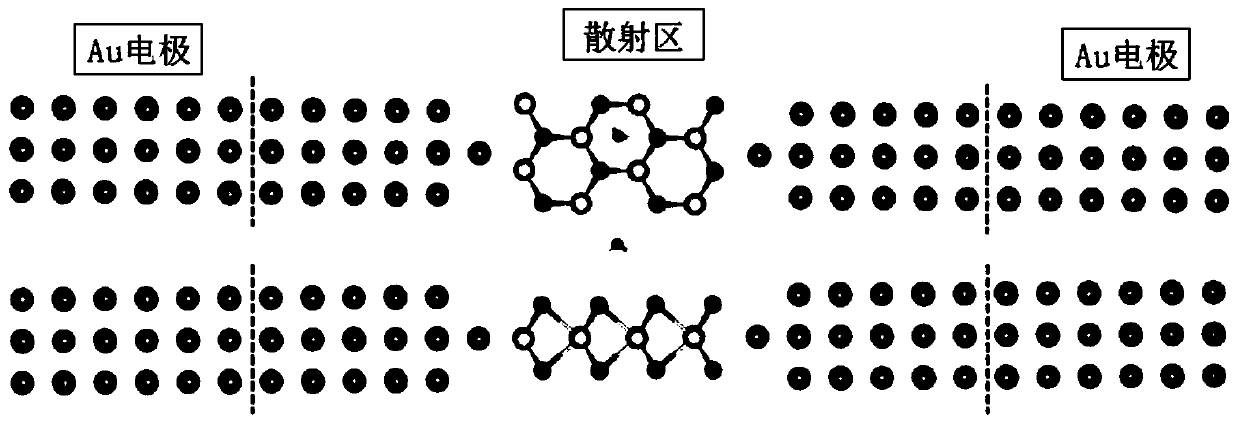

[0034] 1. Obtain a single-layer WS 2 Surface features of : Monolayer WS retrieved from expert database 2 surface features. Based on the first principles of quantum mechanics simulation calculation The thickness in the Z direction is Consistent with expert database results. Constructing simulated surface structures for adsorbed gas molecules such as figure 2 As shown in the middle part, the model is a two-dimensional plane, and the thickness of the vacuum layer is

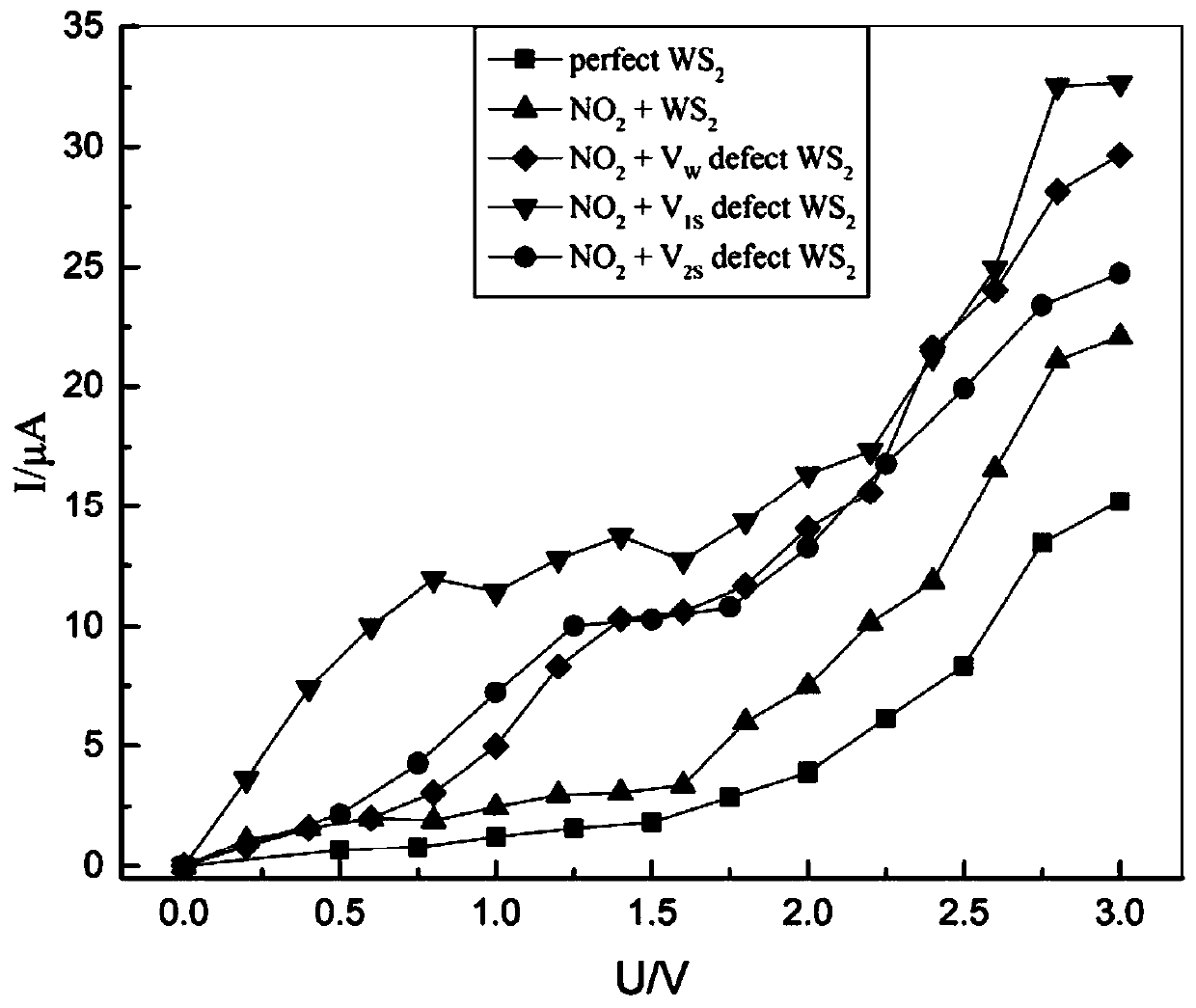

[0035] 2. Get NO 2 In single layer WS 2 Surface and single-layer WS with defects 2 Adsorption energies on surfaces: optimizing NO by first-principles calculations 2 Molecules adsorbed on WS 2 and flawed WS 2 The structure of various adsorption positions on the surface and the corresponding adsorption energy are obtained, and the adsorption ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com