Elastic conductor composite film and preparation method thereof

A technology of conductor compounding and thermoplastic elastomers, which is applied in the direction of cable/conductor manufacturing, equipment for manufacturing conductive/semiconductive layers, conductive layers on insulating carriers, etc., can solve the problems of not having elastic conductors, etc., and achieve conductivity Strong, excellent electrical stability, good economic applicability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

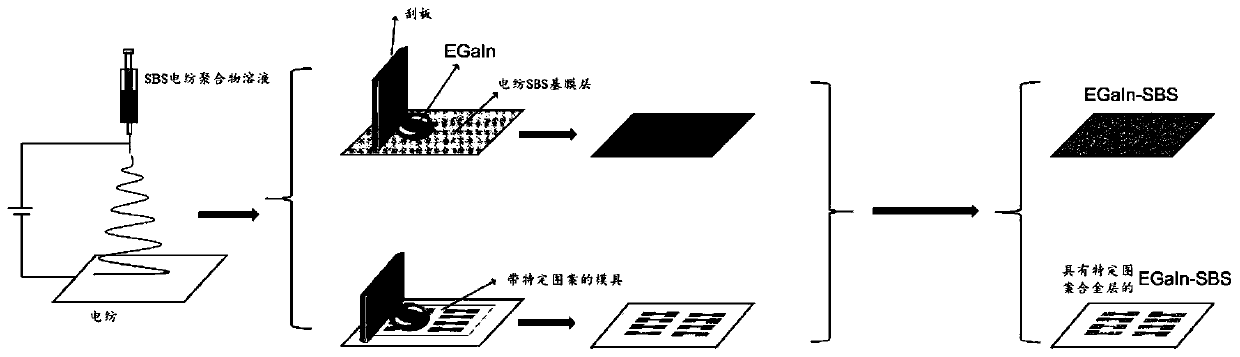

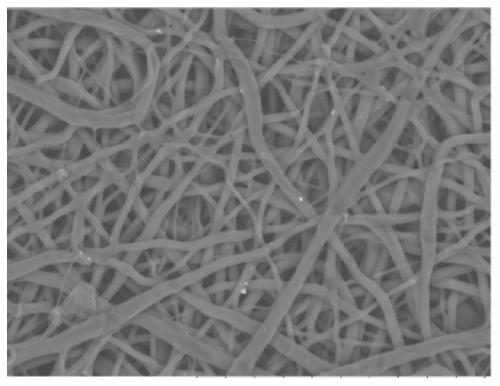

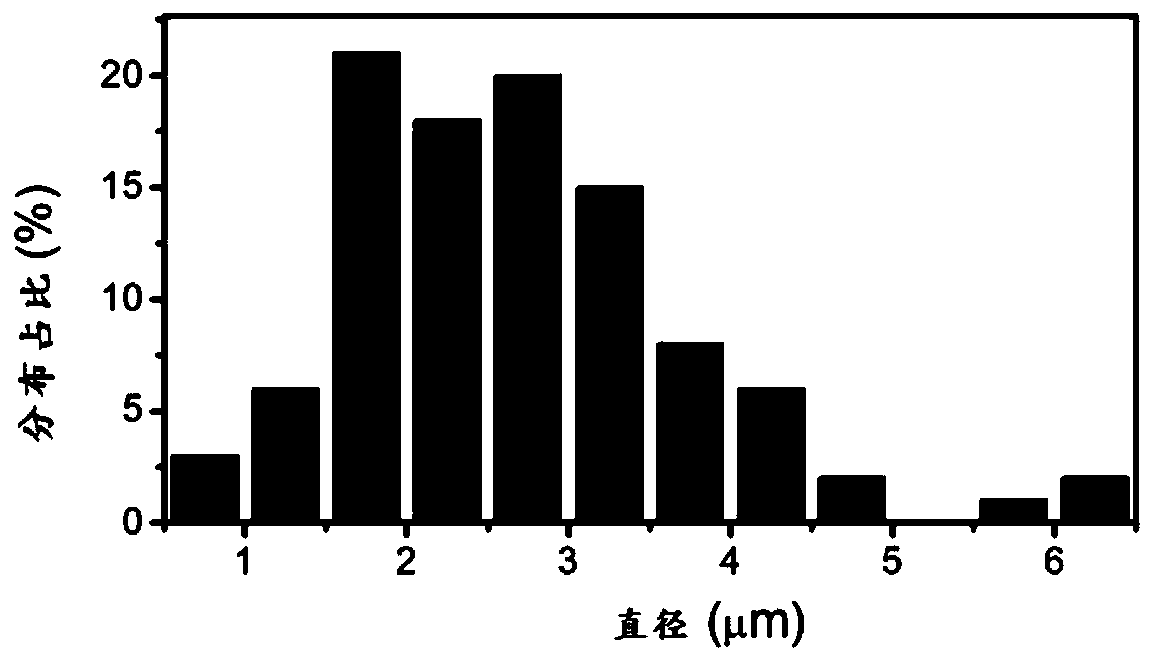

[0068] see figure 1 , the present embodiment provides an elastic conductor composite film and a preparation method thereof, the composite film includes a base film layer and a coating material coated on the surface of the base film layer, wherein the base film layer is an electrospinnable thermoplastic elastomer, coated The cladding material is a liquid metal whose melting point is lower than room temperature.

[0069] It should be understood that the electrospinnable thermoplastic elastomers used include styrene-butadiene-styrene block copolymer (SBS), hydrogenated styrene-butadiene block copolymer (SEBS), benzene Ethylene-isoprene-styrene block copolymer (SIS), hydrogenated styrene / isoprene block copolymer (SEPS), polyester block copolymer (TPEE), polyurethane block copolymer (TPU), polyolefin copolymer (TPO), thermoplastic vulcanizate (TPV), diene block copolymer (TPB) and a series of thermoplastic elastomers that can be used for electrospinning, the present invention does...

Embodiment 2

[0084] see Figure 12 , in order to further improve the electrical conductivity of the composite film, this embodiment provides another elastic conductor composite film and its preparation method, on the basis of Example 1, a nano-silver conductive layer is formed between the base film layer and the alloy layer, thereby The purpose of significantly improving the electrical conductivity of the composite film is achieved.

[0085] The method for preparing the base film layer and the alloy layer in this embodiment is the same as that in Example 1, the difference is that a nano-silver conductive layer (silver nanoparticles, AgNPs) needs to be formed on the base film layer before coating the alloy layer, and the specific steps are:

[0086] Preparation of nano-silver solution, dissolving silver trifluoroacetate (AgTFA) in ethanol (EtOH) to obtain a solution with a concentration of 0.1-1g / mL;

[0087] Soak the basement film layer in nano-silver solution, reducing agent and absolute...

Embodiment 3

[0092] see Figure 16 , the present embodiment provides a three-layer elastic conductor composite film and a preparation method thereof, and particularly relates to an elastic conductor composite film applied to a wearable thermotherapy device. Wherein the preparation method of the base film layer and the alloy layer is the same as in Example 1, the difference is that the formation of the base film layer and the alloy layer is carried out alternately, the base film layer is formed first, and the alloy layer is formed after, and each time the alloy layer is scraped Form the required specific pattern on the base film layer, so it is easy to understand that each layer of elastic conductor composite film includes a base film layer and an alloy layer, and the three-layer structure elastic conductor composite film according to the electrospinning sequence of the base film layer It is represented as the top layer, the middle layer, and the bottom layer in turn, wherein the top layer ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| tensile strain | aaaaa | aaaaa |

| electrical conductivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com