A coaxial-to-microstrip connector and assembly method suitable for cavity filters

A cavity filter and connector technology, applied in the microwave field, achieves the effect of simplifying the assembly method, reducing the insertion loss and improving the overall performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

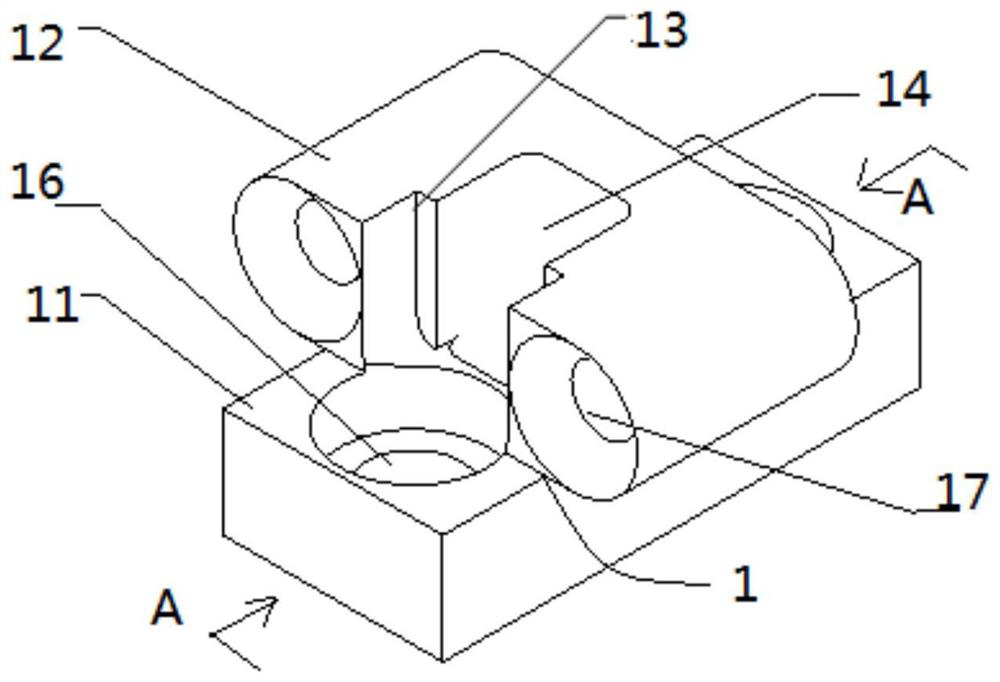

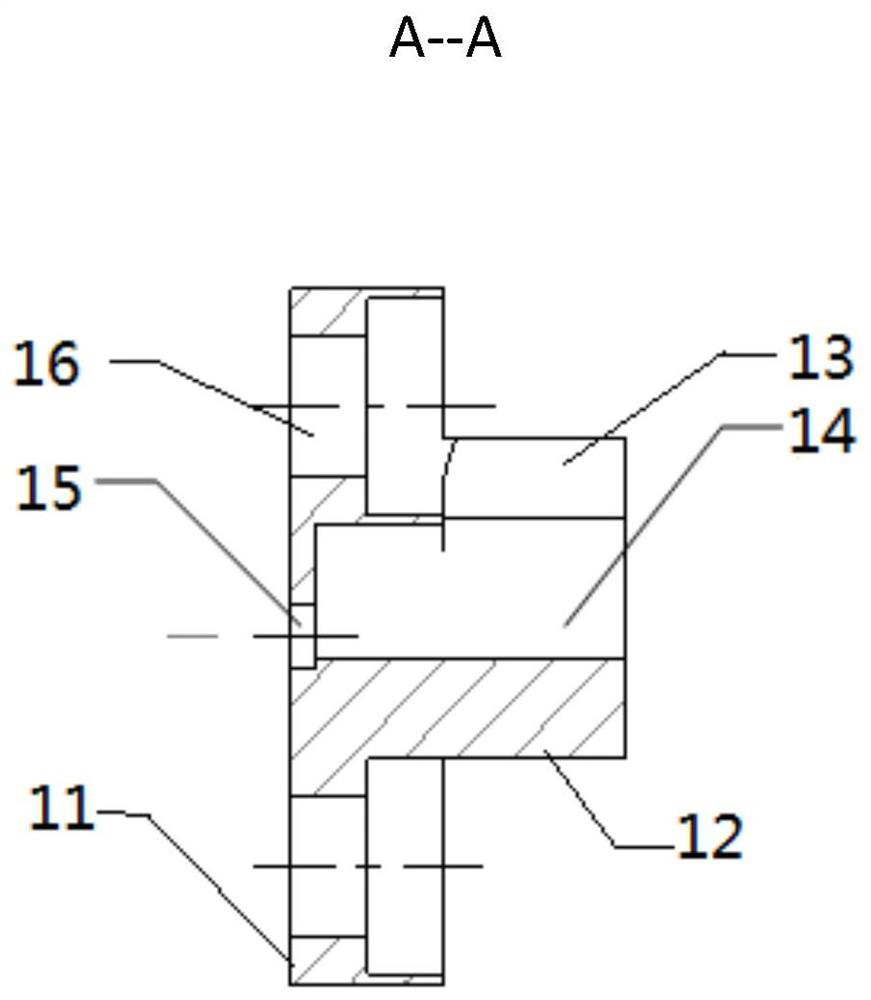

[0035] A coaxial-to-microstrip connector suitable for cavity filters provided in Embodiment 1, please refer to figure 1 and figure 2 As shown, including the base body 1, a microstrip cavity 14 is provided on one side of the base body 1, and an air transition cavity 15 penetrating to the other side of the base body 1 is opened at the end of the microstrip cavity 14 away from the opening, adding a section of the air transition cavity is beneficial to The standing wave at the connection between the cavity filter and the microwave circuit is improved, and at the same time, the insertion loss caused by the use of the cavity filter in the microwave circuit will be greatly reduced, thereby improving the overall performance of the integrated microwave circuit. The air transition cavity is located between the cavity filter insulation terminal and the microstrip cavity, and the impedance transformation characteristics between the coaxial and microstrip can be adjusted. The depth and di...

Embodiment 2

[0042] This embodiment 2 provides an assembly method for a coaxial-to-microstrip connector suitable for cavity filters. When using it, please refer to Figure 4 As shown, before installing the main structure (coaxial to microstrip connector), it is necessary to lay the microstrip line 4 in the microstrip cavity 14 of the main structure, and then install the main structure on the input of the cavity filter through the transverse mounting flange. The output end 3 is to make the inner conductor 7 of the insulated terminal of the cavity filter (hereinafter referred to as the inner conductor) lapped on the pre-laid microstrip line 4 in the microstrip cavity of the main structure, and the inner conductor and the main structure microstrip are connected by welding. The microstrip lines in the cavity 14 are connected together to realize electrical interconnection between the cavity filter and the microstrip lines. Finally, the cavity filter with the main structure installed is embedded...

Embodiment 3

[0048] Embodiment 3 provides test results of a microstrip-to-coaxial connector suitable for a coaxial-to-microstrip connector of a cavity filter.

[0049]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com