Phase change energy storage material filled with ardealite, phase change energy storage plate and preparation method thereof

A phase-change energy storage material and phase-change energy storage technology are applied in heat exchange materials, chemical instruments and methods, buildings, etc., which can solve the problems of easy leakage of phase-change materials, low thermal conductivity, and increased construction process complexity. and other problems, to achieve the effect of high utilization rate of phase change heat, good heat transfer performance, and improvement of living comfort

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

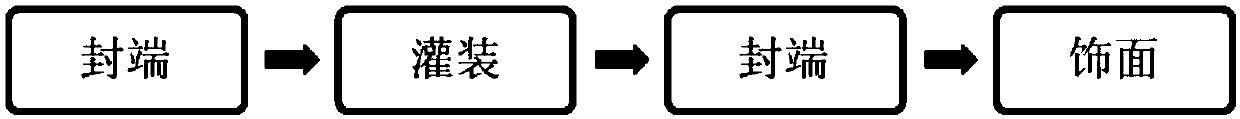

[0059] Such as figure 1 As shown, a preparation method of a phase change energy storage board filled with phosphogypsum, including capping, filling, capping, and finishing, specifically includes the following steps:

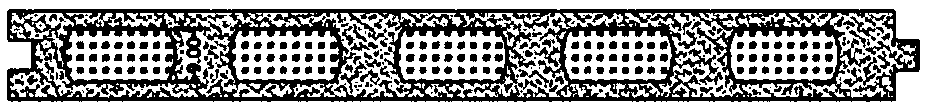

[0060] S1 encapsulates one end of the substrate, leaving one end of the substrate open. Preferably, the substrate is a porous stone plastic plate.

[0061] S2 Weigh 5-38 parts by weight of the inorganic phase change material, place the container containing the phase change material in a 60-degree constant temperature water bath to completely melt it into a liquid state, add 2-25 parts by weight of expanded graphite, and Stir at a circular speed for 3-5 minutes, then place the container in a vacuum oven for adsorption for 4 hours, take it out and cool it down to room temperature naturally to obtain a solid mixed powder.

[0062] S3 Weigh 0-1 parts by weight of citric acid, 0-3 parts by weight of polypropylene fiber, and 0.1-3 parts by weight of water reducer, an...

Embodiment

[0071] Table 1 shows some examples of the specific content of each component in the phase change energy storage material filled with phosphogypsum of the present invention. It should be pointed out that the specific content of each component of the phase change energy storage material filled with phosphogypsum of the present invention is not limited to the data in Table 1, and the water is added according to the actual water-to-paste ratio.

[0072] Table 1 Example of component content of phase change energy storage materials filled with phosphogypsum

[0073]

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size distribution | aaaaa | aaaaa |

| porosity | aaaaa | aaaaa |

| porosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com