A ternary material for lithium batteries coated with negative temperature coefficient material

A negative temperature coefficient, ternary material technology, applied in electrical components, battery electrodes, secondary batteries, etc., can solve the problems of insignificant improvement, side reactions, and deterioration of material cycle stability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 2

[0057] Molar ratio is Ni in the step (1) 2+ :Co 2+ :Mn 2+ =5:2:3. The rest are the same as in Reference Example 1.

[0058] Reference example 3

[0059] Molar ratio is Ni in the step (1) 2+ :Co 2+ :Mn 2+ =6:2:2. The rest are the same as in Reference Example 1.

example 4

[0061] Molar ratio is Ni in the step (1) 2+ :Co 2+ :Mn 2+ =8:1:1. The rest are the same as in Reference Example 1.

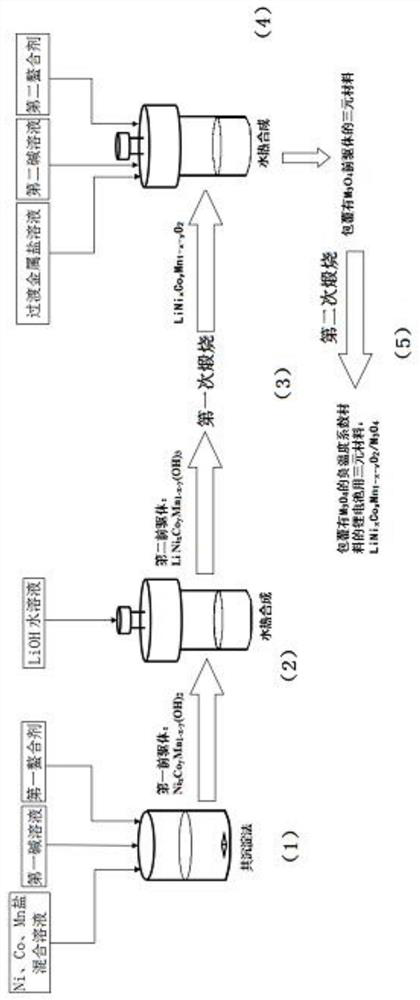

Embodiment 1

[0063] (1) Set the molar ratio to Ni 2+ :Co 2+ :Mn 2+ =3:3:3, Ni, Co, Mn sulfate mixed solution with a concentration of 0.5mol / L is pumped into the continuously stirred tank reactor, and 1mol / L NaOH solution and 0.5mol / L ammonia water are pumped simultaneously Thoroughly stir to obtain the first precursor;

[0064] (2) Put the first precursor in a high-pressure reactor and add 1mol / L LiOH aqueous solution, and keep it at 250°C for 36 hours to obtain the second precursor;

[0065] (3) Calcining the second precursor at a certain temperature for a period of time to obtain the ternary material LiNi x co y mn 1-x-y o 2 (0

[0066] (4) The ternary material LiNi x co y mn 1-x-y o 2 Mix with a solvent and put it into a high-pressure reactor, and at the same time add a certain concentration of Co, Mn, Ni and / or Al salt solution into the high-pressure reactor of the precursor II, and add a certain concentration of alkali solution and chelating agent to fully stir...

PUM

| Property | Measurement | Unit |

|---|---|---|

| electrical resistivity | aaaaa | aaaaa |

| electrical resistivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com