Passive house thermal insulation wallboard and preparation method thereof

A technology for thermal insulation wall panels and passive houses, applied in ceramic products, other household appliances, applications, etc., can solve the problem of thermal insulation performance and waterproof and fireproof performance not meeting the requirements of construction engineering, thermal insulation material performance, waste of land Resource and energy issues, to achieve the effect of improving surface quality and shock resistance, good flame retardancy, and improving dispersion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

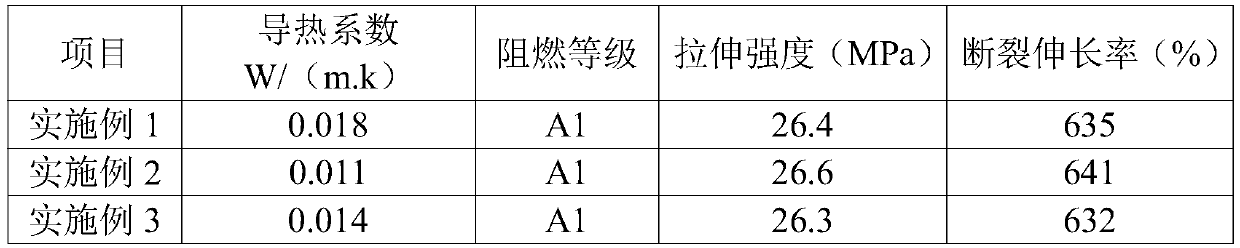

Embodiment 1

[0026] Passive house insulation wall panels are made of the following raw materials in parts by weight: construction waste 50kg; slag 5kg; talcum powder 1kg; glass cellulose 5kg; foaming agent 3kg; river sand 15kg; kg.

[0027] The preparation method specifically comprises the following steps:

[0028] (1) Take each raw material by the weight of the above-mentioned passive house insulation wallboard;

[0029] (2) Put the construction waste, slag, talcum powder and glass cellulose together into a ball mill for fine grinding for 1 hour to obtain a finely ground mixed dry material; control the finely ground mixed dry material to 3mm;

[0030] (3) Put the above-mentioned finely ground mixed dry material, hydroxyethyl cellulose, foaming agent and water into a stirring device and stir fully at a stirring speed of 700r / s, and foam at a temperature of 80°C for 80min to obtain a foam slurry;

[0031] (4) Mix the above-mentioned foaming slurry with river sand and wood calcium and sti...

Embodiment 2

[0033] Passive house insulation wall panels are made of the following raw materials in parts by weight: construction waste 60kg; slag 8kg; talcum powder 2kg; glass cellulose 7kg; foaming agent 4kg; river sand 20kg; kg.

[0034] The preparation method specifically comprises the following steps:

[0035] (1) Take each raw material by the weight of the above-mentioned passive house insulation wallboard;

[0036] (2) Put the construction waste, slag, talcum powder and glass cellulose together into a ball mill for fine grinding for 2 hours to obtain a finely ground mixed dry material; control the finely ground mixed dry material to 1mm;

[0037] (3) Put the finely ground mixed dry material, hydroxyethyl cellulose, foaming agent and water into the stirring equipment to fully stir at a stirring speed of 750r / s, and foam at 85°C for 70min to obtain foamed slurry material;

[0038] (4) Mix the foamed slurry with river sand and wood calcium and stir evenly to obtain a mixture, inject...

Embodiment 3

[0040] Passive house thermal insulation wall panels are made of the following raw materials in parts by weight: construction waste 70kg; slag 10kg; talcum powder 3kg; glass cellulose 10kg; foaming agent 5kg; river sand 18kg; kg.

[0041] The preparation method specifically comprises the following steps:

[0042] (1) Take each raw material by the weight of the above-mentioned passive house insulation wallboard;

[0043] (2) Put the construction waste, slag, talcum powder and glass cellulose into a ball mill and grind them together for 1.5 hours to obtain a finely ground mixed dry material; control the finely ground mixed dry material to 2mm;

[0044] (3) Put the finely ground mixed dry material, hydroxyethyl cellulose, foaming agent and water into the stirring equipment to fully stir at a stirring speed of 800r / s, and foam at 90°C for 60min to obtain foamed slurry material;

[0045] (4) Mix the foamed slurry with river sand and wood calcium and stir evenly to obtain a mixtur...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com