Self-diagnosis gas density relay and using method thereof

A gas density, relay technology, applied in the field of electric power, can solve problems such as hazards, flashovers, and reduction of insulation strength on the surface of insulating parts

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

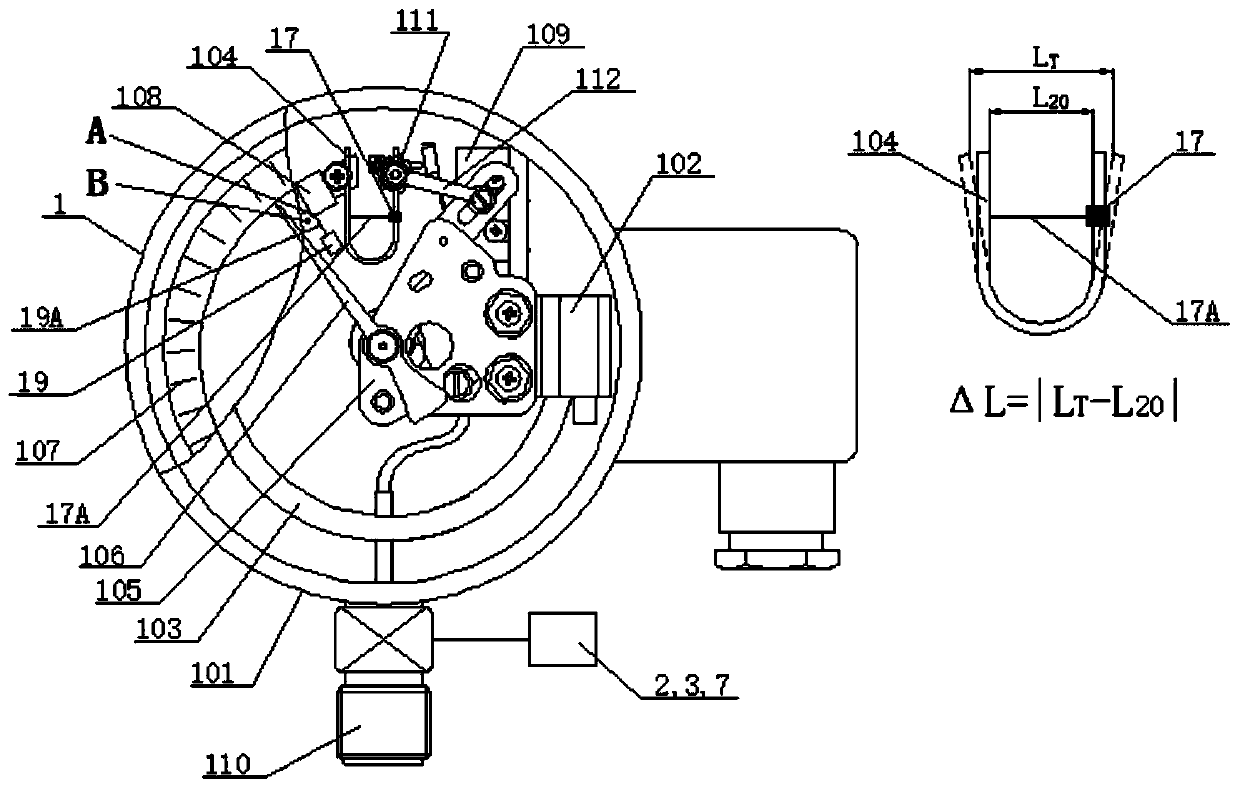

[0132] like figure 1 As shown, a self-diagnosing gas density relay or gas density monitoring device mainly includes: a gas density relay body 1, a gas density detection sensor (ie, a pressure sensor 2 and a temperature sensor 3), an intelligent control unit 7, and a diagnostic sensor 17 and Diagnostic sensor 19. Wherein, the pressure sensor 2, the temperature sensor 3 and the intelligent control unit 7 are arranged on the connector 110 for connecting electrical equipment. On the gas path, the pressure sensor 2 of the gas density detection sensor communicates with the gas density relay body 1 . The pressure sensor 2 , the temperature sensor 3 , the diagnostic sensor 17 and the diagnostic sensor 19 are respectively connected with the intelligent control unit 7 . The gas density relay or gas density monitoring device also includes a mutual self-calibration unit, and the data detected by the mutual self-calibration unit is compared through the intelligent control unit 7 to reali...

Embodiment 2

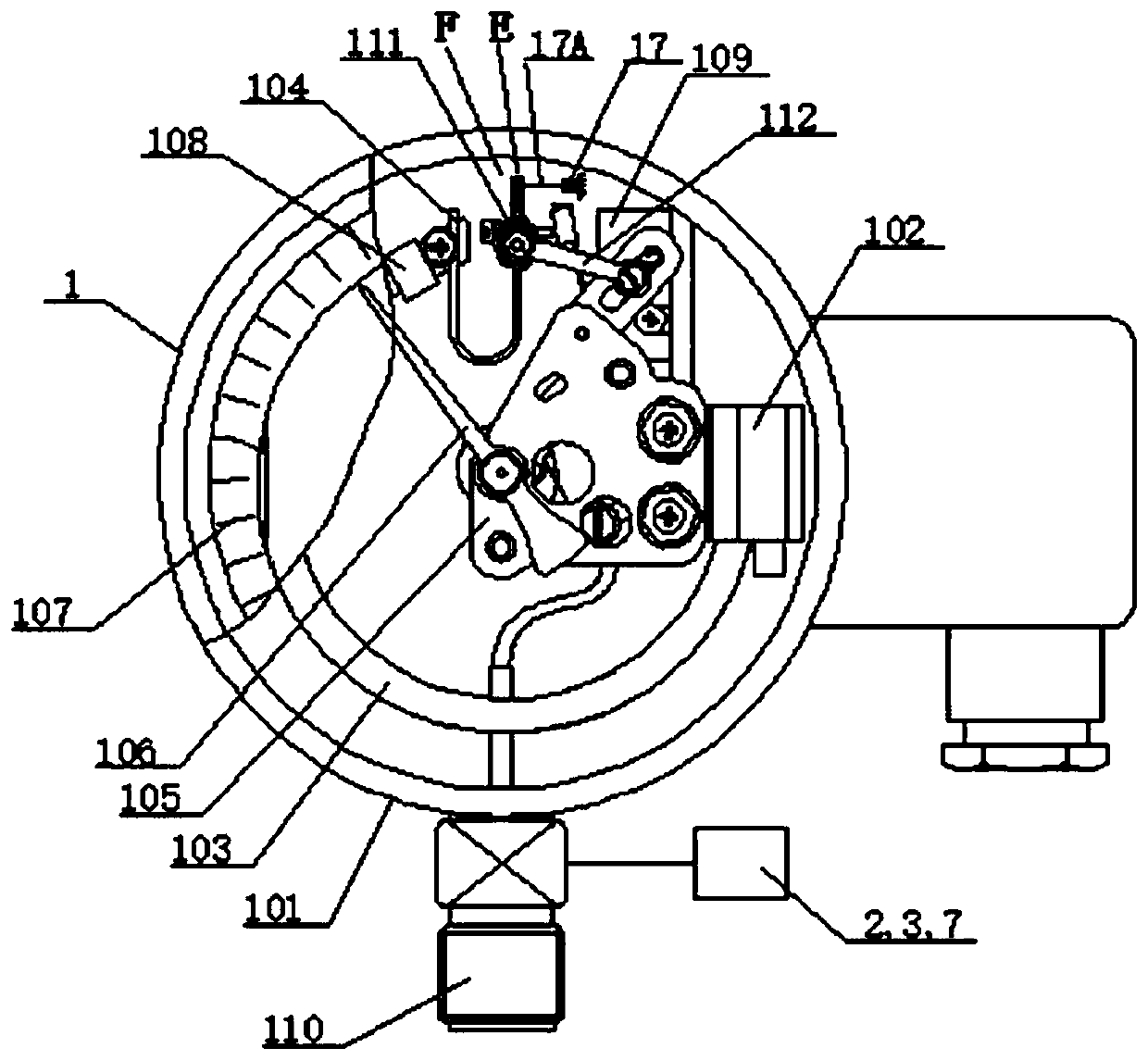

[0140] like figure 2 As shown, a self-diagnosing gas density relay or gas density monitoring device mainly includes: gas density relay body 1, gas density detection sensors (pressure sensor 2 and temperature sensor 3), intelligent control unit 7 and diagnostic sensor 17. Wherein, the pressure sensor 2, the temperature sensor 3 and the intelligent control unit 7 are arranged on the connector 110 for connecting electrical equipment. On the gas path, the pressure sensor 2 of the gas density detection sensor communicates with the gas density relay body 1 . The pressure sensor 2, the temperature sensor 3 and the diagnostic sensor 17 are respectively connected with the intelligent control unit 7. The gas density relay or gas density monitoring device also includes a mutual self-calibration unit, and the data detected by the mutual self-calibration unit is compared through the intelligent control unit 7 to realize maintenance-free; The detected data is compared to realize maintena...

Embodiment 3

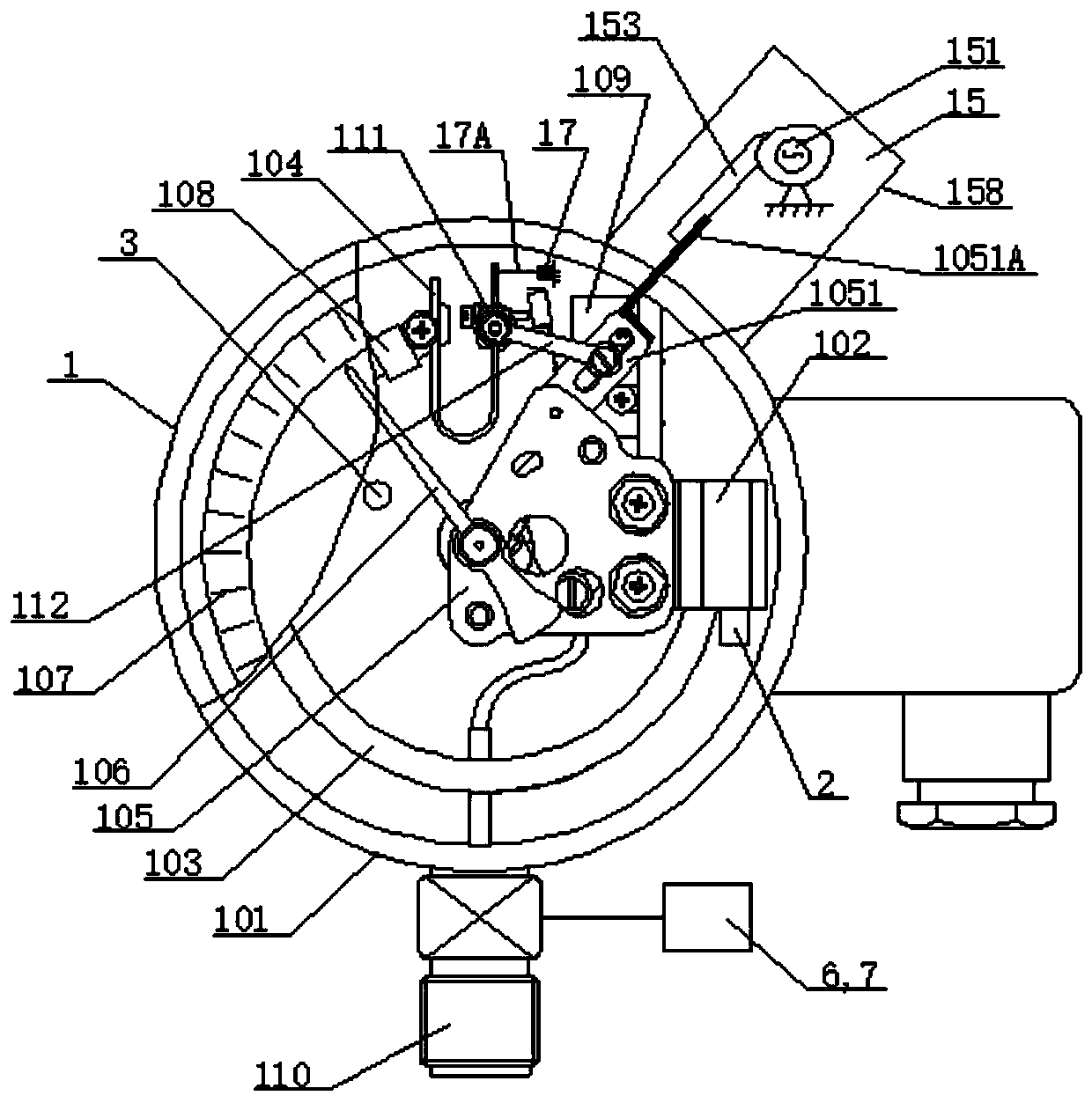

[0145] like image 3 As shown, the self-diagnosing gas density relay or gas density monitoring device of Embodiment 3 of the present invention includes: a gas density relay body 1, a pressure sensor 2, a temperature sensor 3, an actuating contact action mechanism 15, and an online verification contact signal sampling unit 6. Intelligent control unit 7 and diagnostic sensor 17. The online verification contact signal sampling unit 6 and the intelligent control unit 7 are arranged on the connector 110 for connecting electrical equipment. The driving contact action mechanism 15 is arranged outside the housing 101 .

[0146] Specifically, the gas density relay body 1 includes a housing 101, and a base 102, an end seat 108, a pressure detection element 103, a temperature compensation element 104, a number of signal generators 109, and a movement 105 arranged in the housing 101. , Pointer 106, Dial 107. Wherein, one end of the pressure detection element 103 is fixed on the base 10...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com