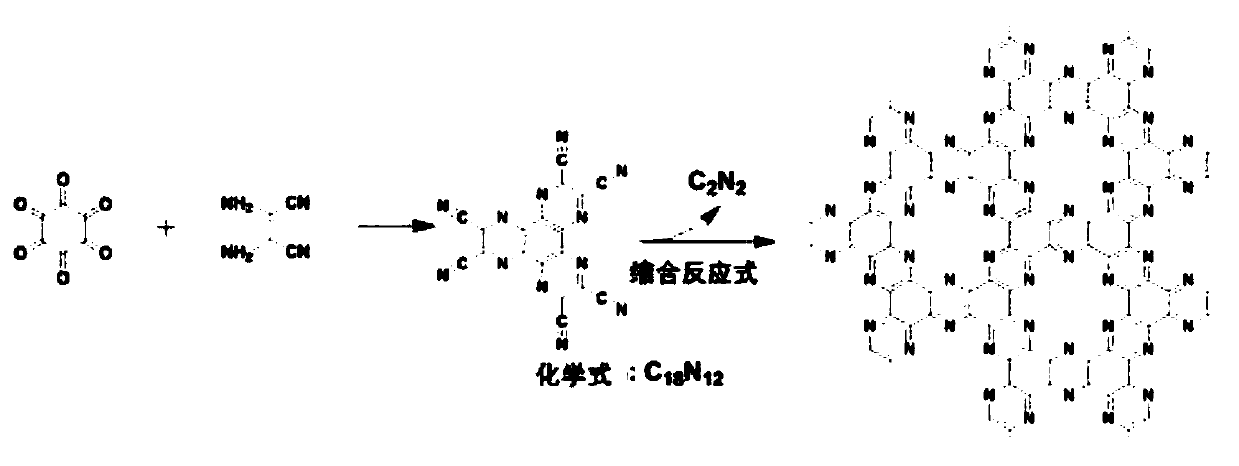

Covalent organic framework material, preparation method and application thereof

A covalent organic framework and suspension technology, which is applied in the preparation/purification of carbon, electrode manufacturing, electrical components, etc., can solve the problems of poor conductivity and large molecular weight, and achieve the effect of low synthesis equipment requirements and novel structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

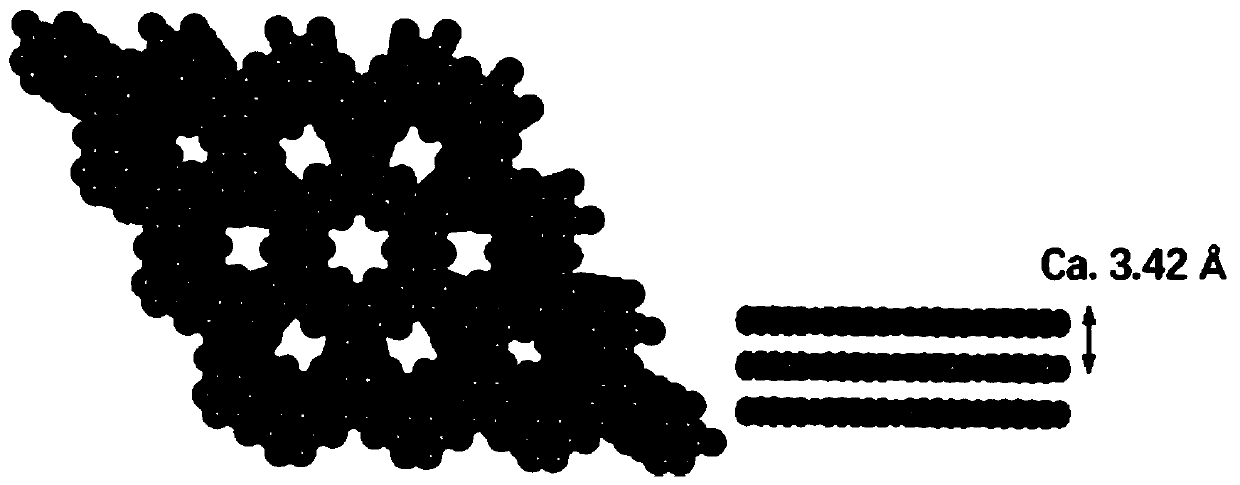

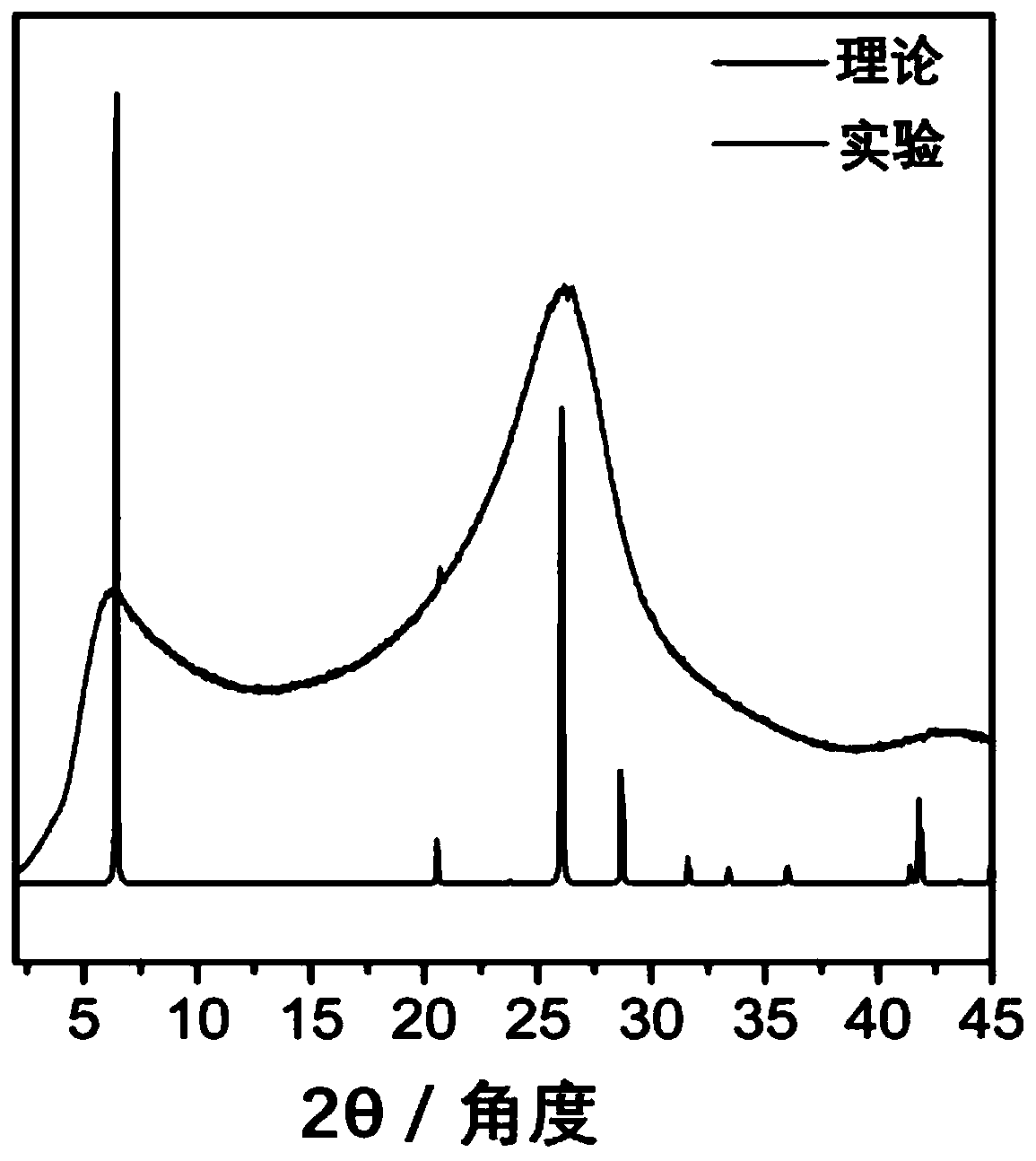

Embodiment 1

[0042] Reflux cyclohexanone octahydrate (4g, 12.6mmol) and diaminomaleonitrile (10.88g, 100.8mmol) in AcOH (150mL) for 2h, filter the black suspension while hot, and wash with hot AcOH (3× 25mL) to give a black solid, which was suspended in 30% HNO 3 (60 mL) and heated at 100 °C for 3 h to obtain a hot dark brown suspension which was poured into ice water (200 mL) and cooled overnight, the suspension was filtered and the solid was dissolved in MeCN ( 400 mL) for 2 hours and filtered. The filtrate was evaporated in vacuo to give an orange solid (2.4 g, 50% yield) hexaazatribenzohexacarbonitrile (HAT-CN). COF-CN was prepared by carbonizing HAT-CN (500 mg) in a horizontal tube furnace under nitrogen flow for 1 h at different temperatures from room temperature to 80 °C, and the heating ramp was set at 2 °C min -1 , from 80°C to 700°C respectively set to 4°C·min -1, to prepare COF-CN, denoted as COF-CN700.

[0043] COF-CN700, PVDF, and KS6 were formulated into a mixture at a ma...

Embodiment 2

[0046] Reflux cyclohexanone octahydrate (4g, 12.6mmol) and diaminomaleonitrile (10.88g, 100.8mmol) in AcOH (150mL) for 2h, filter the black suspension while hot, and wash with hot AcOH (3× 25mL) to give a black solid, which was suspended in 30wt% HNO 3 (60 mL) and heated at 100 °C for 3 h to give a hot dark brown suspension which was poured into ice water (200 mL) and cooled overnight. The suspension was filtered and the solid was refluxed in MeCN (400 mL) for 2 hours and filtered, the filtrate was evaporated in vacuo to give an orange solid (2.4 g, 50% yield) hexaazatribenzohexacarbonitrile (HAT-CN). COF-CN was prepared by carbonizing HAT-CN (500 mg) at different temperatures for 1 hour under nitrogen flow in a horizontal tube furnace. The different temperatures are from room temperature to 80°C, and the heating ramp is set to 2°C min -1 , from 80°C to 900°C respectively set to 4°C·min -1 , the covalent organic framework material COF-CN was prepared, denoted as COF-CN900. ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com