Niobium pentoxide (at) reduced graphene oxide catalyst and preparation method and application thereof

A technology of niobium pentoxide and graphene, applied in the field of catalysis, can solve the problem of low selectivity of sulfoxide, and achieve the effect of improving catalytic efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

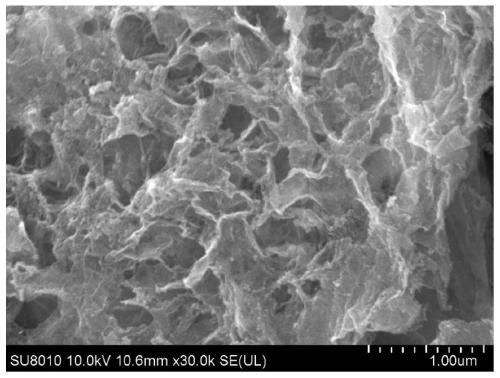

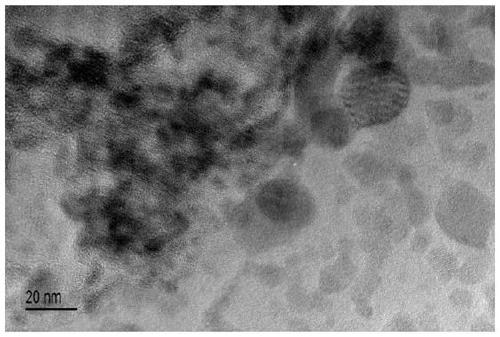

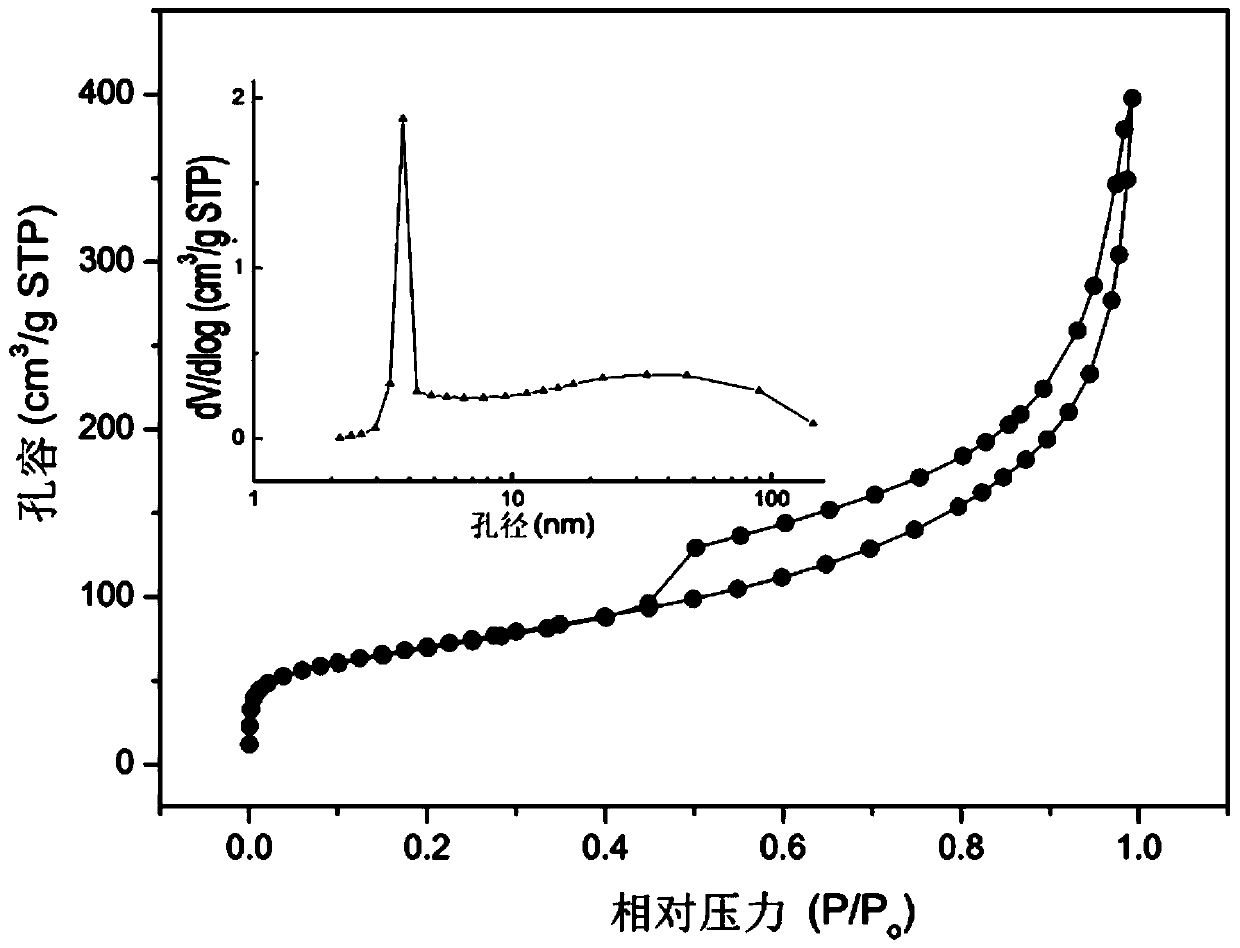

[0030] This embodiment provides a niobium pentoxide@reduced graphene oxide catalyst, the niobium pentoxide@reduced graphene oxide catalyst is prepared by the following steps:

[0031] (1) Add 0.15 g of N,N′-dicyclohexylcarbodiimide to 50 mL of graphene oxide dispersion with a concentration of 1 mg / mL, heat to 90° C. under sufficient stirring, and reflux for 3 h, then Stand still and cool to room temperature to obtain a mixed solution containing modified graphene oxide.

[0032] (2) Dissolve 0.3g of niobium pentachloride in 15mL of absolute ethanol to prepare an organic solution of niobium pentachloride with a concentration of 0.2g / mL. Then add the mixture in step (1) under ice bath, and stir in ice bath for 2h. Then transferred to a 50mL hydrothermal reaction kettle, and hydrothermally reacted at 190°C for 15h. The hydrothermal product was centrifuged (9000rpm, 5min) to obtain a solid, which was washed twice with deionized water and absolute ethanol, and finally washed once ...

Embodiment 2

[0036] This embodiment provides a preparation method of niobium pentoxide@reduced graphene oxide catalyst, comprising the following steps:

[0037] (1) Add 0.2 g of N,N'-dicyclohexylcarbodiimide to 100 mL of graphene dispersion with a concentration of 1 mg / mL, heat to 90°C under sufficient stirring, reflux for 3 hours, and then statically Set aside, cooled to room temperature.

[0038] (2) Dissolve 1.0 g of niobium pentachloride in 20 mL of absolute ethanol to prepare an organic solution of niobium pentachloride with a concentration of 0.5 g / mL. Then add the mixture in step (1) under ice bath, and stir in ice bath for 2h. Then transferred to a 50mL hydrothermal reaction kettle, and hydrothermally reacted at 180°C for 15h. The hydrothermal product was centrifuged (9000rpm, 5min) to obtain a solid, which was washed twice with deionized water and absolute ethanol, and finally washed once with deionized water, and then freeze-dried to obtain niobium pentoxide@reduced graphene ox...

Embodiment 3

[0040] This embodiment provides a preparation method of niobium pentoxide@reduced graphene oxide catalyst, comprising the following steps:

[0041] (1) Add 0.2 g of N,N'-dicyclohexylcarbodiimide to 100 mL of graphene dispersion with a concentration of 2 mg / mL, heat to 90°C under sufficient stirring, reflux for 3 hours, and then statically Set aside, cooled to room temperature.

[0042] (2) Dissolve 0.5 g of niobium pentachloride in 10 mL of absolute ethanol, then add the mixture in step (1) under ice bath, and stir in ice bath for 2 h. Then transferred to a 50mL hydrothermal reaction kettle, and hydrothermally reacted at 160°C for 15h. The hydrothermal product was centrifuged (9000rpm, 5min) to obtain a solid, which was washed twice with deionized water and absolute ethanol, and finally washed once with deionized water, and then freeze-dried to obtain niobium pentoxide@reduced graphene oxide catalyst.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com