Highly-dispersed nanowire-shaped nickel-cobalt oxide material and highly-dispersed nanowire-shaped nickel-cobalt sulfide material, and preparation methods thereof

A technology of nickel-cobalt oxide and nickel-cobalt sulfide, which is applied in the direction of nickel oxide/nickel hydroxide, nickel sulfide, nanotechnology, etc., can solve the problems of limited diversified dispersion and mixing treatment, high production cost, and poor reproducibility , to achieve high yield, good reproducibility and good dispersion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

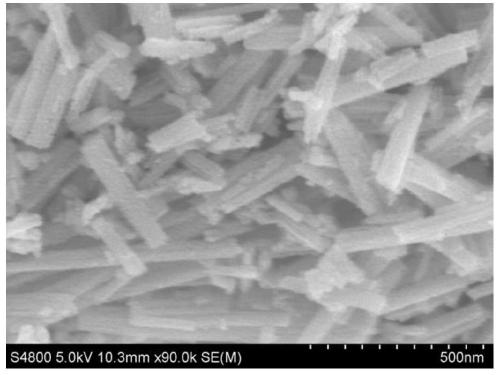

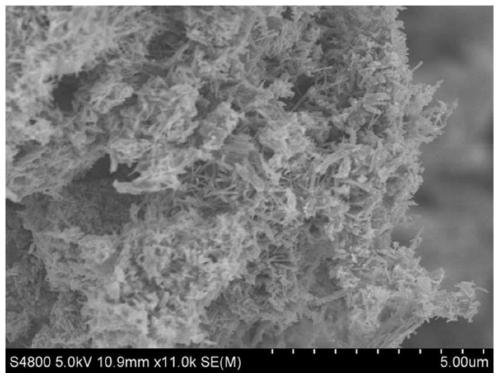

[0032] The invention discloses a method for preparing a highly dispersed nanowire-shaped nickel-cobalt oxide material, wherein the nanowire-shaped nickel-cobalt oxide can be abbreviated as Nanowire-NiCo 2 o 4 , including the following steps,

[0033] Step 1, uniformly disperse carbon spheres, nickel salt, cobalt salt and weak base in deionized water, let stand for 5-100h to make carbon spheres fully absorb nickel ions and cobalt ions to obtain mixed system A;

[0034] Among them, first disperse the carbon spheres in deionized water, stir and disperse evenly, then add nickel salt, cobalt salt and weak base to stir and disperse evenly, to obtain a uniformly dispersed mixed system A, so that the adsorption of carbon spheres can be fully exerted, carbon spheres The average particle size is 200-500nm, the concentration is 0.1-1mol / L, the concentration of nickel salt is 0.001-0.05mol / L, the concentration of cobalt salt is 0.002-0.1mol / L, the concentration of weak base is 0.1-0.3mol...

Embodiment 1

[0044] A Highly Dispersed Nanowire-NiCo 2 o 4 The preparation method of material comprises the following steps,

[0045] Step 1, configure a carbon sphere solution with a concentration of 0.1mol / L, first ultrasonic and cell crushing in an ultrasonic cell pulverizer for 15 minutes, then fully stir and disperse until uniform under ultrasonic, and Ni(NO 3 ) 2 ·6H 2 O and Co(NO 3 ) 2 ·6H 2 O was added to the carbon sphere solution at a molar ratio of 1:2, stirred and dispersed evenly, then added urea, and left to stand for 24 hours to obtain a uniformly dispersed suspension; the Ni(NO 3 ) 2 ·6H 2 The concentration of O is 0.008mol / L, Co(NO 3 ) 2 ·6H 2 The concentration of O is 0.016mol / L, and the concentration of urea is 0.13mol / L;

[0046] Step 2, transfer the suspension to a 100ml reaction kettle, react at 180°C for 10h, cool the suspension to room temperature naturally, wash with deionized water and ethanol for 3 times and suction filter to remove impurities in the ...

Embodiment 2

[0050] A Highly Dispersed Nanowire-NiCo 2 o 4 The preparation method of material comprises the following steps,

[0051] Step 1, prepare a carbon sphere solution with a concentration of 0.5mol / L, first ultrasonically and finely pulverize in an ultrasonic cell pulverizer for 15 minutes, then fully stir and disperse until uniform under ultrasonic, and NiCl 2 ·6H 2 O and CoCl 2 ·6H 2 O is added to the carbon sphere solution at a molar ratio of 1:2, stirred and dispersed evenly, then added ammonia water, and left to stand for 5 hours to obtain a uniformly dispersed suspension; the NiCl in the suspension 2 ·6H 2 The concentration of O is 0.01mol / L, CoCl 2 ·6H 2 The concentration of O is 0.02mol / L, and the concentration of ammonia water is 0.1mol / L;

[0052] Step 2, transfer the suspension to a 100ml reactor, react at 120°C for 15h, cool the suspension to room temperature naturally, wash with deionized water and ethanol for 3 times and suction filter to remove impurities in ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com