A highly dispersed nanowire-shaped nickel-cobalt oxide and nickel-cobalt sulfide material and its preparation method

A technology of nickel-cobalt oxide and nickel-cobalt sulfide, applied in the direction of nickel oxide/nickel hydroxide, nickel sulfide, nanotechnology, etc., can solve the problems of insufficient output, poor reproducibility, high production cost, etc., and achieve good reproducibility , high yield, and the effect of improving dispersibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

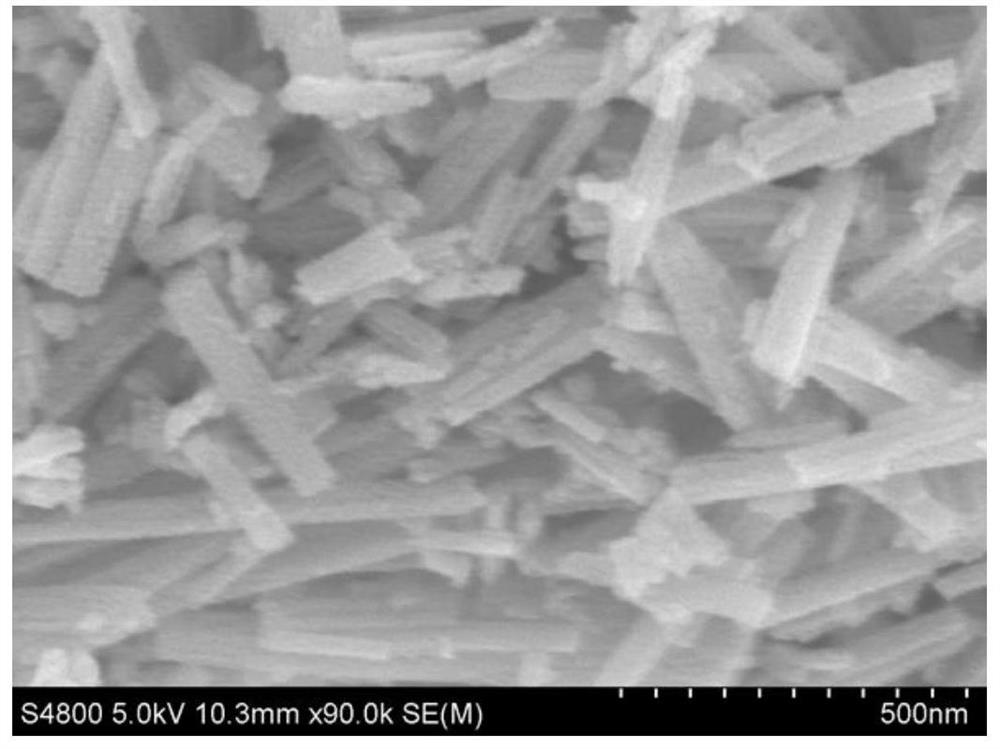

[0032] The invention discloses a method for preparing a highly dispersed nanowire-shaped nickel-cobalt oxide material, wherein the nanowire-shaped nickel-cobalt oxide can be abbreviated as Nanowire-NiCo 2 o 4 , including the following steps,

[0033] Step 1, uniformly disperse carbon spheres, nickel salt, cobalt salt and weak base in deionized water, and let the carbon spheres fully absorb nickel ions and cobalt ions to obtain mixed system A after standing for 5-100 hours;

[0034] Among them, first disperse the carbon spheres in deionized water, stir and disperse evenly, then add nickel salt, cobalt salt and weak base to stir and disperse evenly, to obtain a uniformly dispersed mixed system A, so that the adsorption of carbon spheres can be fully exerted, carbon spheres The average particle size is 200-500nm, the concentration is 0.1-1mol / L, the concentration of nickel salt is 0.001-0.05mol / L, the concentration of cobalt salt is 0.002-0.1mol / L, the concentration of weak base...

Embodiment 1

[0044] A Highly Dispersed Nanowire-NiCo 2 o 4 The preparation method of material comprises the following steps,

[0045] Step 1, configure a carbon sphere solution with a concentration of 0.1mol / L, first ultrasonic and cell crushing in an ultrasonic cell pulverizer for 15 minutes, then fully stir and disperse until uniform under ultrasonic, and Ni(NO 3 ) 2 ·6H 2 O and Co(NO 3 ) 2 ·6H 2 O was added to the carbon sphere solution at a molar ratio of 1:2, stirred and dispersed evenly, then added urea, and left to stand for 24 hours to obtain a uniformly dispersed suspension; the Ni(NO 3 ) 2 ·6H 2 The concentration of O is 0.008mol / L, Co(NO 3 ) 2 ·6H 2 The concentration of O is 0.016mol / L, and the concentration of urea is 0.13mol / L;

[0046] Step 2, transfer the suspension to a 100ml reaction kettle, react at 180°C for 10h, cool the suspension to room temperature naturally, wash with deionized water and ethanol for 3 times and suction filter to remove impurities in the ...

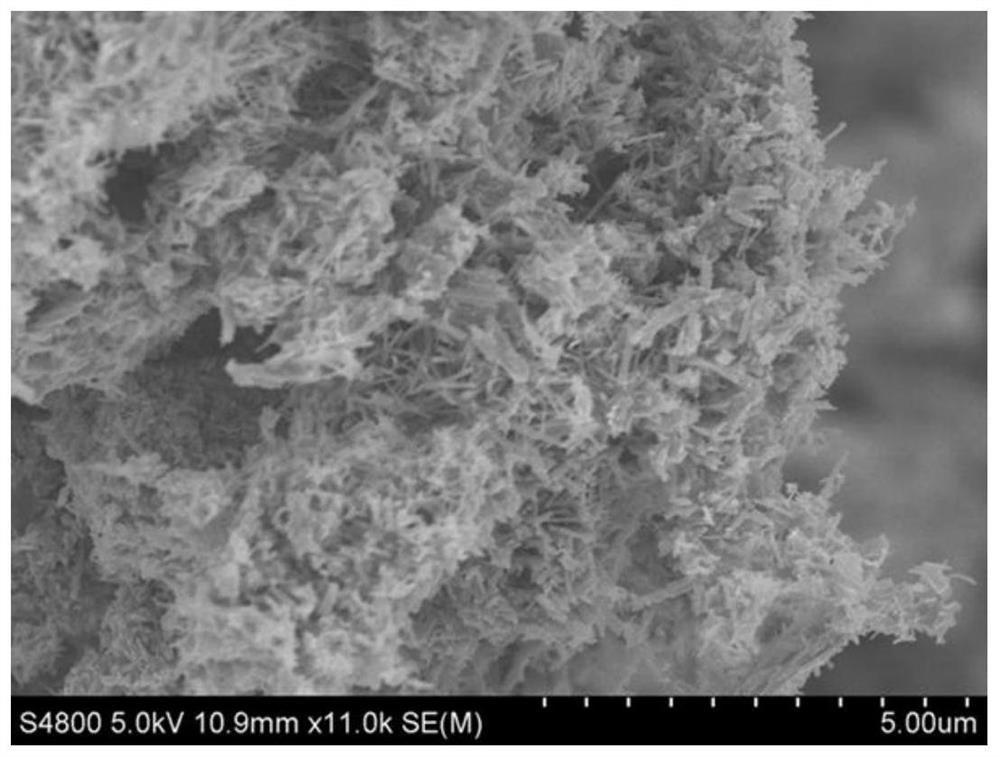

Embodiment 2

[0050] A Highly Dispersed Nanowire-NiCo 2 o 4 The preparation method of material comprises the following steps,

[0051] Step 1, prepare a carbon sphere solution with a concentration of 0.5mol / L, first ultrasonically and finely pulverize in an ultrasonic cell pulverizer for 15 minutes, then fully stir and disperse until uniform under ultrasonic, and NiCl 2 ·6H 2 O and CoCl 2 ·6H 2 O is added to the carbon sphere solution at a molar ratio of 1:2, stirred and dispersed evenly, then added ammonia water, and left to stand for 5 hours to obtain a uniformly dispersed suspension; the NiCl in the suspension 2 ·6H 2 The concentration of O is 0.01mol / L, CoCl 2 ·6H 2 The concentration of O is 0.02mol / L, and the concentration of ammonia water is 0.1mol / L;

[0052] Step 2, transfer the suspension to a 100ml reactor, react at 120°C for 15h, cool the suspension to room temperature naturally, wash with deionized water and ethanol for 3 times and suction filter to remove impurities in ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com