Preparation method of metal ion dosed monodisperse mesoporous silicon dioxide spherical nanoparticles

A mesoporous silica and nanoparticle technology, applied in metal/metal oxide/metal hydroxide catalysts, chemical instruments and methods, chemical/physical processes, etc. Divided into single and other problems, to achieve the effect of reducing synthesis cost, reducing environmental pollution, and eliminating tedious steps

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

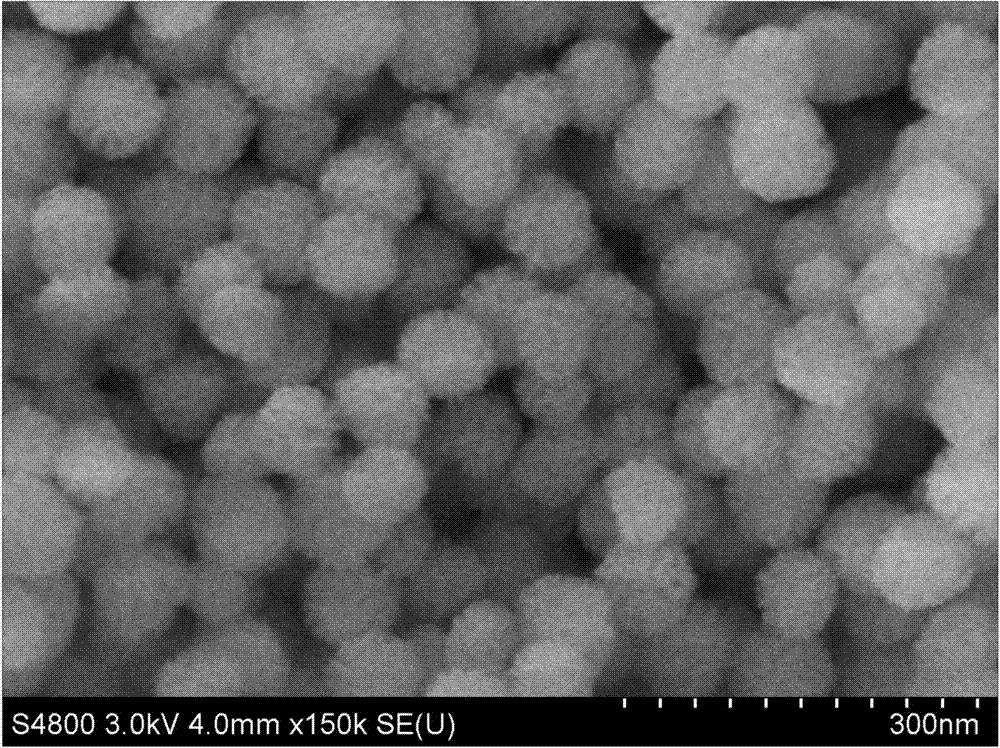

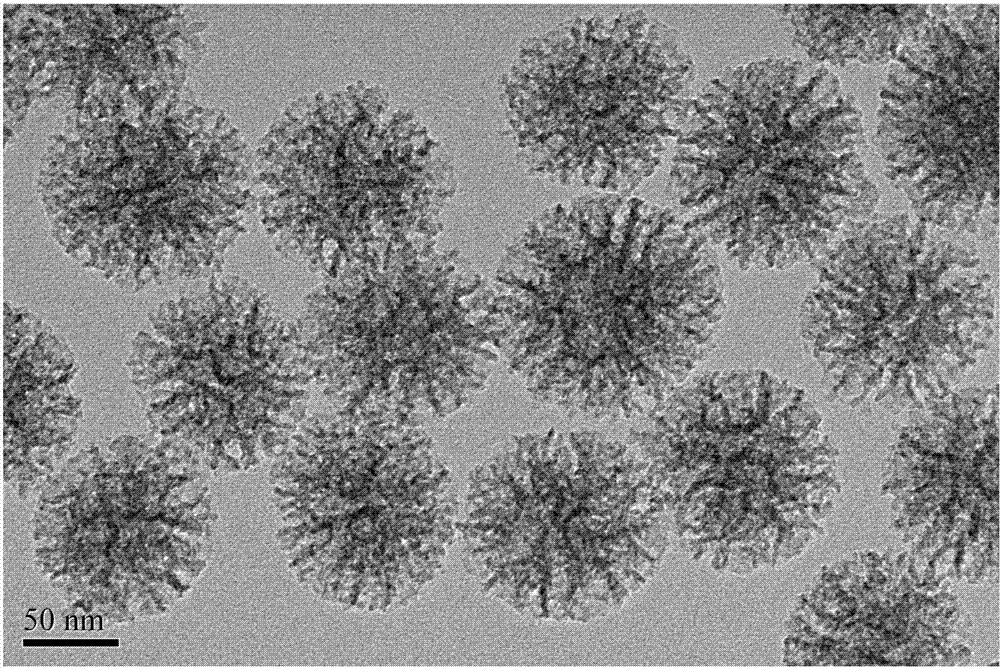

[0029] First, 2.74g of cetyltrimethylammonium p-toluenesulfonate (CTATos) was added to 144ml of deionized water, 14.92g of triethanolamine (TEAH 3 ) in a beaker, stirred at 80°C for 1 hour until the solution became clear, then quickly added 20.83g of tetraethoxysilicate (TEOS) and 0.68g of tetrabutyl titanate (TBOT) into the beaker, at 80°C Continue to stir at constant temperature for 2 hours to obtain a white precipitate, and the molar composition of the mixture is SiO 2 :CTATos:TEAH 3 :TBOT:H 2 O = 1:0.06:1:0.02:80; the obtained mixture is directly suction filtered, washed, and dried to obtain Ti-containing mesoporous SiO 2 Nanoparticles, yield 95%, average particle size 90 nm. The method of high-temperature roasting or acid treatment can remove the surfactant in the channel in one step. The specific method is as follows: (1) 1.0g of raw powder is directly roasted in a muffle furnace at 550°C for 6 hours; (2) 1.0g of raw powder is mixed with 40ml of 1M hydrochloric acid ...

Embodiment 2

[0031] First, 2.74g of cetyltrimethylammonium p-toluenesulfonate (CTATos) was added to a solution containing 144ml of deionized water, 0.15g of triethanolamine (TEAH 3 ) in a beaker, stirred at 80°C for 1 hour until the solution became clear, then quickly added 20.83g of tetraethoxysilicate (TEOS) and 0.77g of zirconium tert-butoxide (TBOZ) into the beaker, and kept at a constant temperature of 80°C Stirring was continued for 2 hours, a white precipitate was obtained, and the molar composition of the mixture was SiO 2 :CTATos:TEAH 3 :TBOZ:H 2 O = 1:0.06:0.01:0.02:80; the obtained mixture is directly filtered, washed, and dried to obtain zirconium-containing mesoporous SiO 2Nanoparticles, yield 93%, average particle size 80 nm, specific surface area 710m 2 / g, 1.8ml / g, pore size 3.1nm.

Embodiment 3

[0033] First, 2.74g of cetyltrimethylammonium p-toluenesulfonate (CTATos) was added to a solution containing 144ml of deionized water, 1.49g of triethanolamine (TEAH 3 ) mixed solution in a beaker, 80 o C was stirred at constant temperature for 1 hour until the solution became clear, then 20.83g of tetraethoxysilicate (TEOS) and 0.40g of triethoxyvanadium oxide (TEOV) were quickly added to the beaker, 80 o C constant temperature continued to stir for 2 hours, a white precipitate was obtained, and the molar composition of the mixture was SiO 2 :CTATos:TEAH 3 :TEOV:H 2 O = 1:0.06: 0.1:0.02:80; the obtained mixture is directly suction filtered, washed, and dried to obtain V-containing mesoporous SiO 2 Nanoparticles, yield 95%, average particle size 80 nm, specific surface area 810m 2 / g, 1.9ml / g, pore size 3.4nm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com