Microstructure refinement and equiaxed crystal transformation method for laser fuse additive manufacturing of titanium alloy components

A technology of additive manufacturing and laser melting, which is applied in the directions of additive manufacturing, additive processing, and process efficiency improvement. It can solve problems such as poor fatigue performance and coarse structure, and achieve the effect of simplifying path planning.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

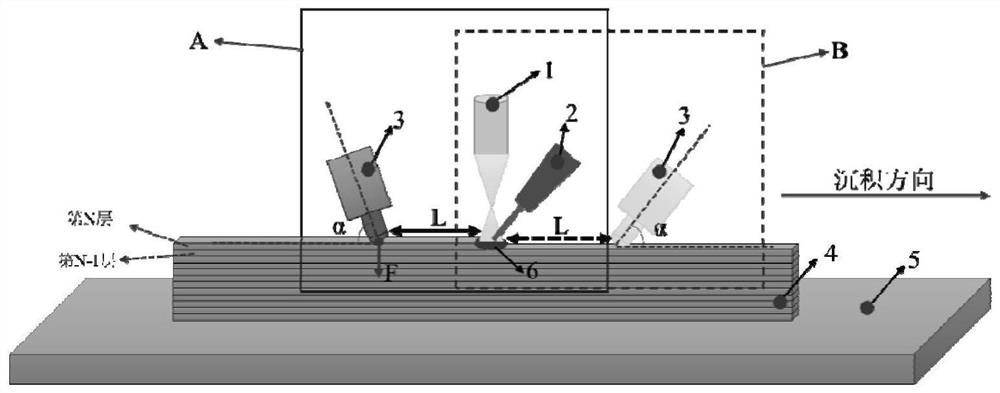

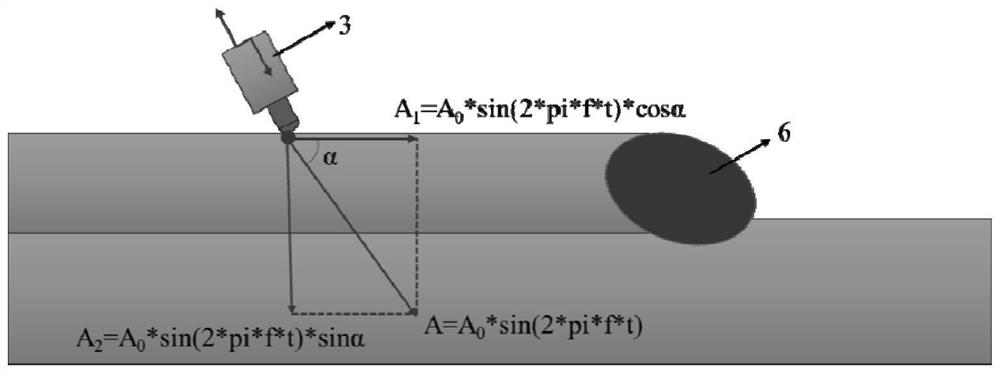

[0034] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

[0035] The purpose of the present invention is to provide a simple method for microstructure refinement and equiaxed grain transformation of titanium alloy components manufactured by laser fuse additive manufacturing. The method couples the ultrasonic impact micro forging device with the laser fuse additive manufacturing device, The high-intensity ultrasonic energy field is introduced into the laser fuse additive manufacturing process, and at the same time exerts the interference effect of the ultrasonic energy field on the molten pool and the impact strengthening effect on the solid deposition layer, so as to improve the equiaxed grain transformation of titanium alloy components and refine the grain size. Particles and improve mechanical properties, solve the problem of coarse structure and poor fatigue performance of titanium alloy i...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com