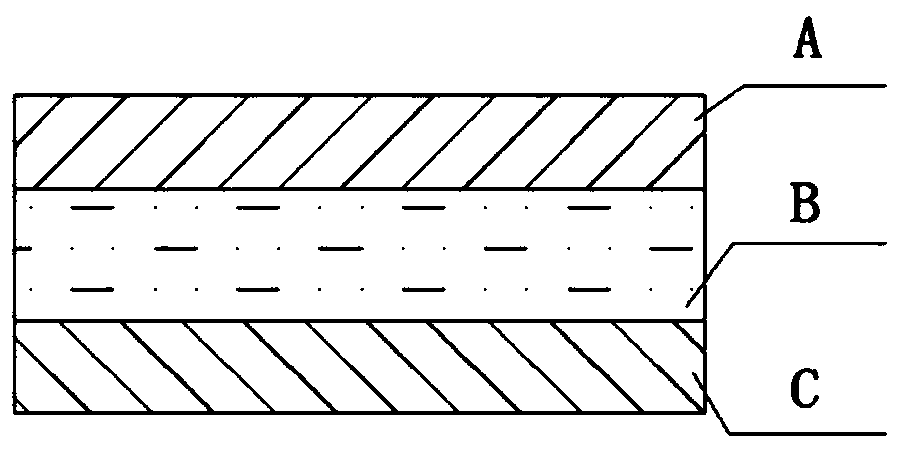

Heat-shrinkable PETG black and white composite film with light shielding performance

A heat-shrinkable, composite film technology, used in household appliances, flexible coverings, other household appliances, etc., can solve the problems of short shelf life, increase production, transportation, storage and other costs, and achieve extended shelf life and secondary processing performance. Excellent and resource-saving effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The polyester used in the present invention is mainly composed of ethylene terephthalate, that is, PETG, which is a transparent, non-crystalline copolyester, and the comonomer commonly used in PETG is 1,4-cyclohexyl Alkanedimethanol (CHDM), the full name is polyethylene terephthalate-1,4-cyclohexanedimethanol. It is a product obtained by polycondensation of three monomers of terephthalic acid (PTA), ethylene glycol (EG) and 1,4-cyclohexanedimethanol (CHDM) by transesterification.

[0034] The implementation case given below is a detailed description of the present invention. At the same time, it is pointed out that the following implementation methods are further detailed explanations of the present invention, and cannot be interpreted as limiting the protection scope of the present invention. Summary of the invention and only making non-essential improvements will still belong to the protection scope of the present invention. The technical solution of the present inve...

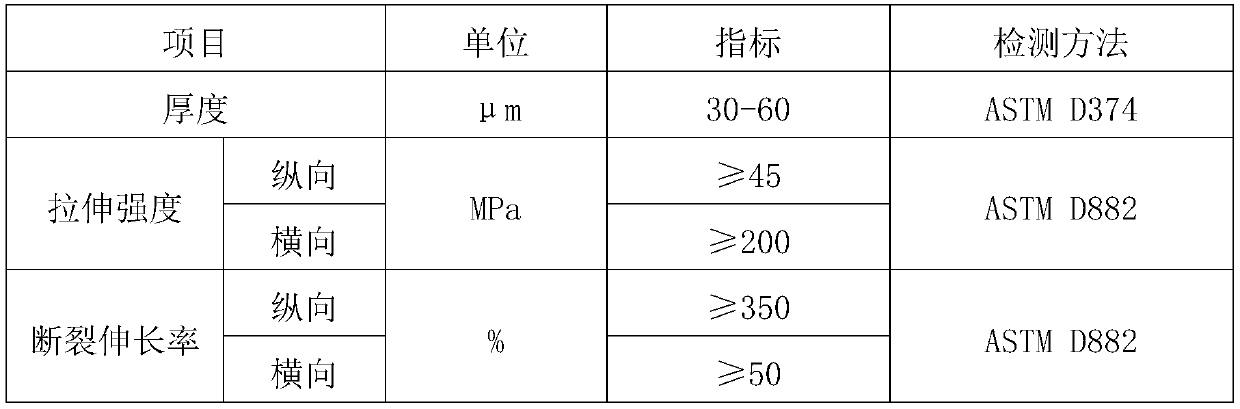

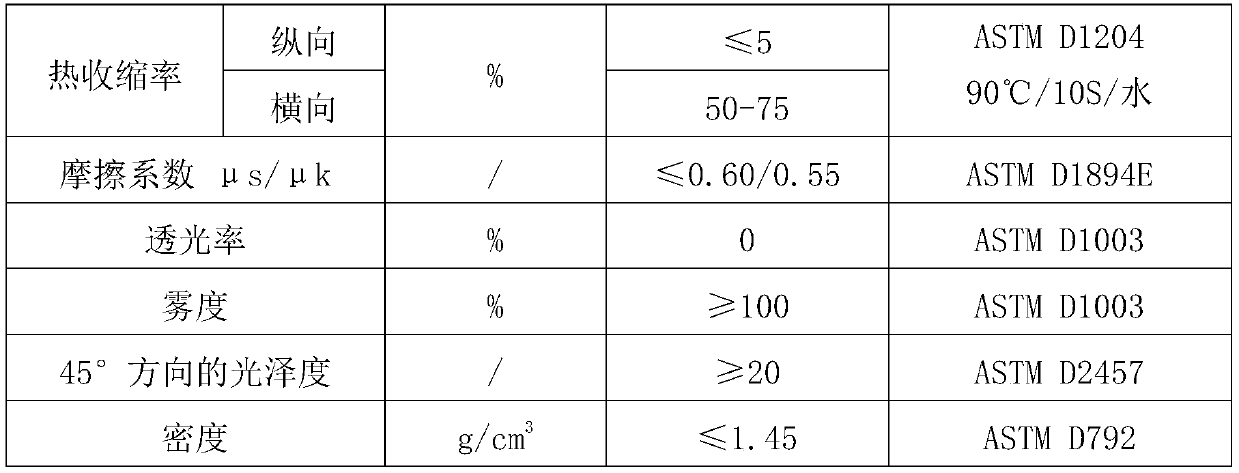

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com