Deep penetration TIG welding perforation state detection device and detection method thereof

A state detection device and deep melting technology, applied in the direction of material excitation analysis, electric excitation analysis, etc., can solve the problems of detection difficulties, and achieve the effects of convenient and simple production and use, stable relationship and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0069] This embodiment provides a device for detecting the perforation state of deep penetration TIG welding based on arc frontal radiation spectrum during deep penetration TIG welding.

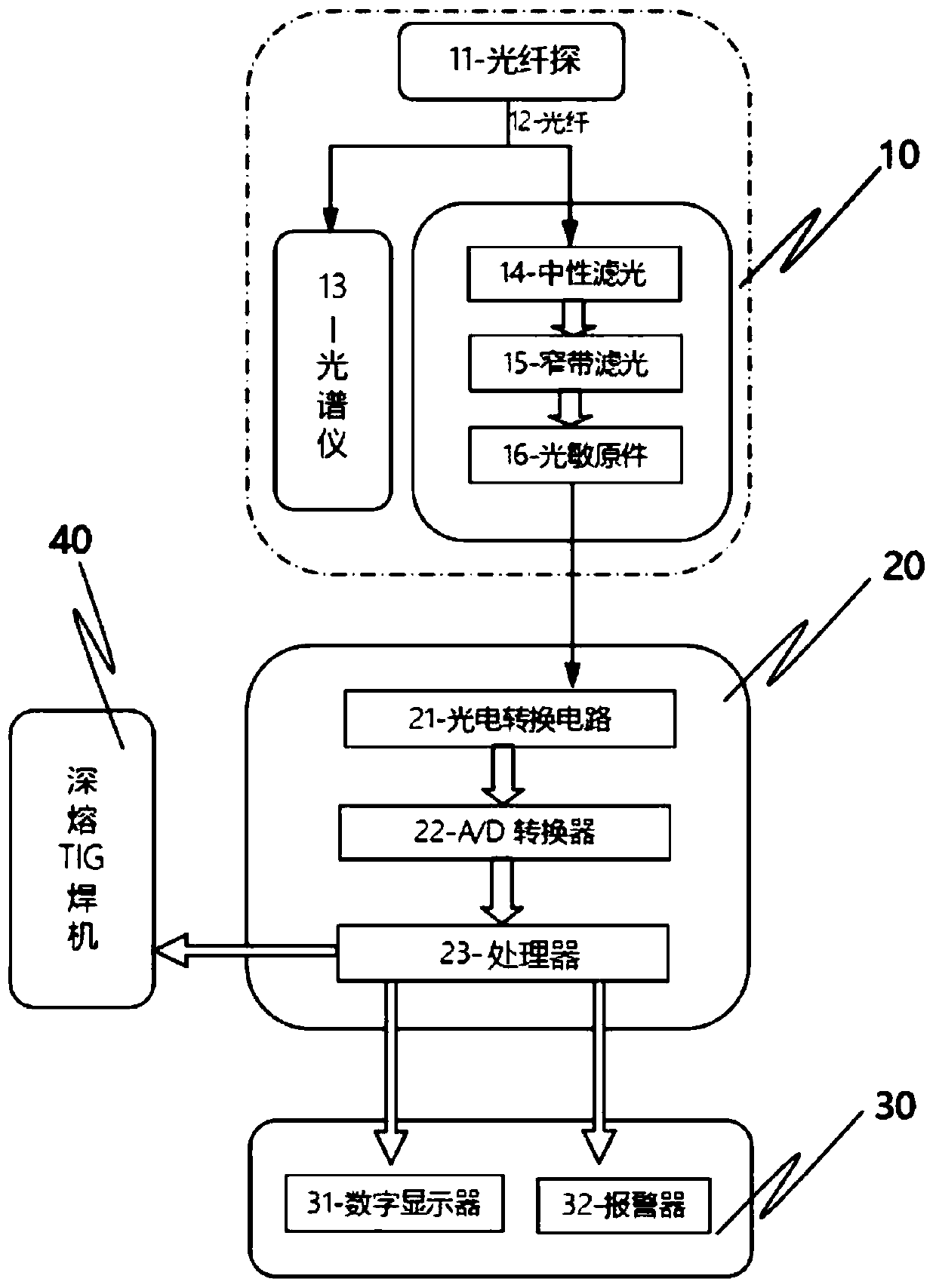

[0070] Such as figure 1 A schematic structural block diagram of a deep penetration TIG welding perforation state detection device provided by an embodiment of the present invention is shown in the following block diagram:

[0071] A deep penetration TIG welding perforation state detection device, including a photosensitive system 10, a measurement and analysis system 20, and a digital display and alarm system 30;

[0072] The photosensitive system 10 is used to detect the characteristic spectral radiation intensity of the metal plasma outside the front edge of the arc during deep penetration TIG welding;

[0073] The measurement and analysis system 20 is connected with the photosensitive system 10, and the measurement and analysis system 20 is used to convert the metal plasma characteristic ...

Embodiment 2

[0101] This embodiment provides a detection method based on the deep penetration TIG welding perforation state detection device provided in the first embodiment.

[0102] A detection method using the deep penetration TIG welding perforation state detection device provided in Embodiment 1 includes the following steps:

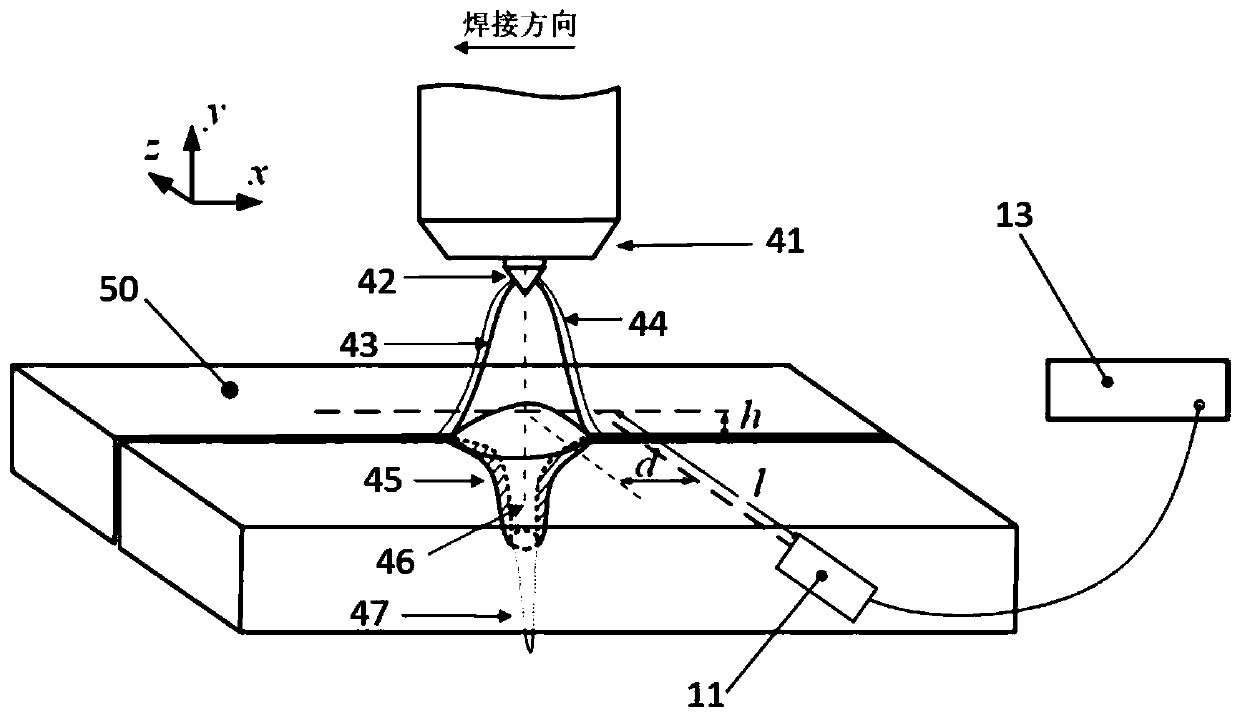

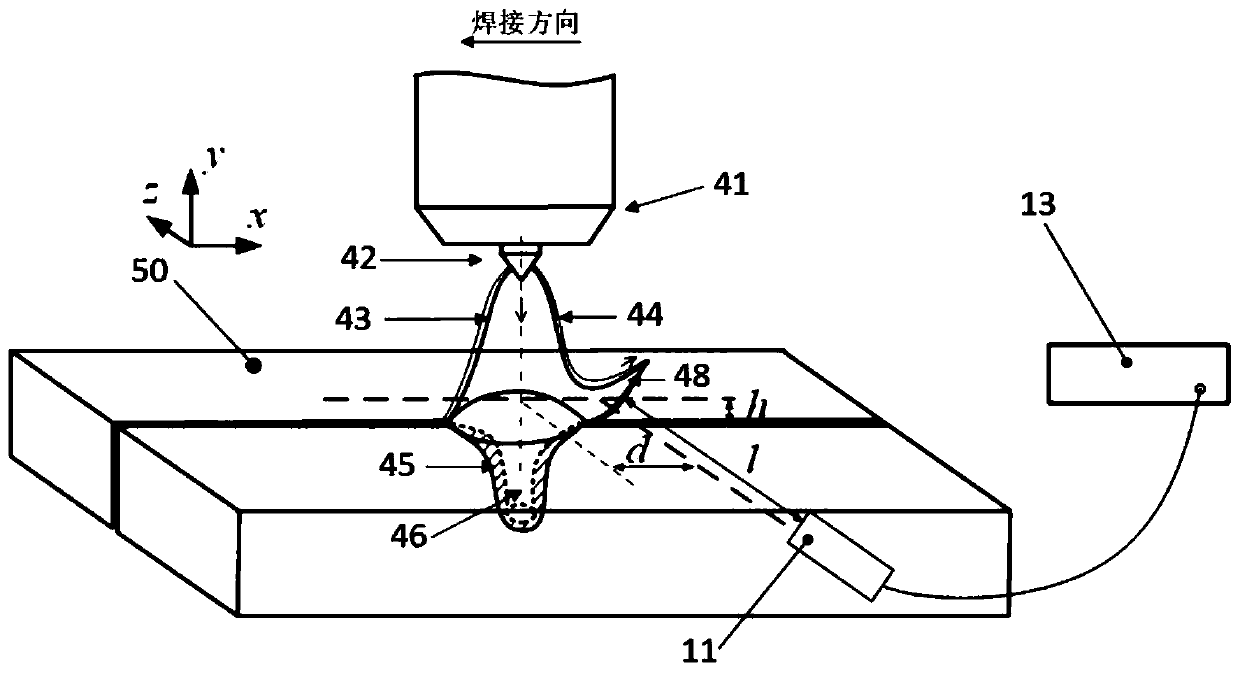

[0103] S1) The photosensitive system in the perforation state detection device of the deep penetration TIG welding is arranged outside the front edge of the arc of the deep penetration TIG welding;

[0104] S2) Connect the measurement and analysis system in the deep penetration TIG welding perforation state detection device with the photosensitive system, and connect the photosensitive system with the digital display and alarm system in the deep penetration TIG welding perforation state detection device ;

[0105] S3) detecting the metal plasma radiated light outside the arc front edge of the deep penetration TIG welding through the photosensitive system, and d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com