Motor insulated bearing chamber

A technology of insulated bearings and bearings, which is applied in the direction of casings/covers/supports, electrical components, electromechanical devices, etc., and can solve the problems that the rotor assembly cannot be effectively insulated, the service life of the device is reduced, and the bearing wears quickly, etc. Achieve the effect of improving the transmission effect of the shaft, facilitating heat dissipation and improving performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

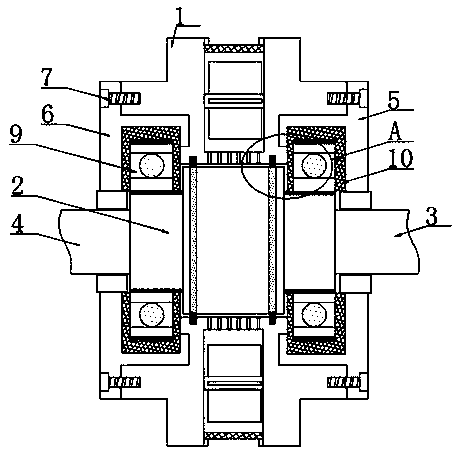

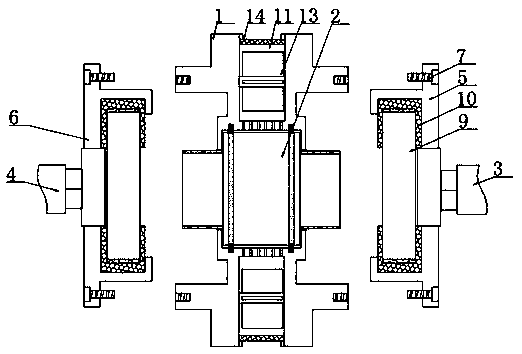

[0028] according to Figure 1-6 The insulating bearing chamber of a motor shown includes a housing 1, a shaft coupling 2 is provided inside the housing 1, and a driving shaft 3 is provided at one end of the coupling 2, and the coupling 2 is far away from the driving shaft 3 is provided with a driven shaft 4, the housing 1 is provided with a front cover 5 on a side close to the driving shaft 3, and a rear cover 6 is provided on a side of the housing 1 close to the driven shaft 4, so Both sides of the housing 1 are provided with first threaded holes, and the surfaces of the front cover 5 and the rear cover 6 are provided with second threaded holes, and the front cover 5 and the rear cover 6 pass through the housing 1. The screw 7 is fixedly connected, and the front cover 5 and the rear cover 6 are fixedly connected with an annular clamp 8, and the axis of the annular clamp 8 is provided with a bearing 9, and the bearing 9 and the annular clamp 8 An insulating layer 10 is provid...

Embodiment 2

[0031] according to Figure 4 As shown in the motor insulation bearing chamber, the outer side of the housing 1 is provided with an annular groove 11, and the bottom of the annular groove 11 is provided with a number of evenly distributed exhaust holes 12, and the exhaust holes 12 are connected with the housing 1 through the inside, the annular groove 11 is provided with a number of evenly distributed cooling fans 13, the honeycomb structure of the insulating layer 10 facilitates the heat dissipation of the bearing 9, the heat enters the annular groove 11 from the exhaust hole 12 and passes through the cooling fan 13 discharge, which is conducive to the long-term work of the motor;

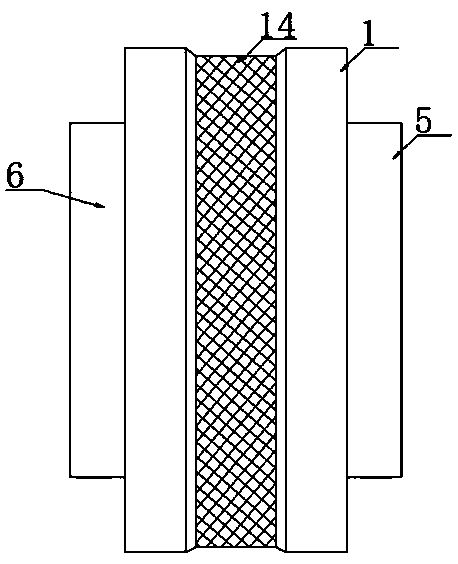

[0032] Further, the top of the annular groove 11 is provided with a dust-proof net 14, the dust-proof net 14 is made of metal material, the dust-proof net 14 is arranged in a strip shape, and the dust-proof net 14 is fixed around the annular At the top of the groove 11, the dust-proof net 14 can ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com