Wind turbine main shaft forging process

A technology for wind power spindles and processes, applied in metal processing equipment, mechanical equipment, engine components, etc., can solve the problems of increasing the difficulty of mandrel extraction, high friction, and reducing processing efficiency, etc., to reduce friction and improve quality Good, the effect of prolonging the service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

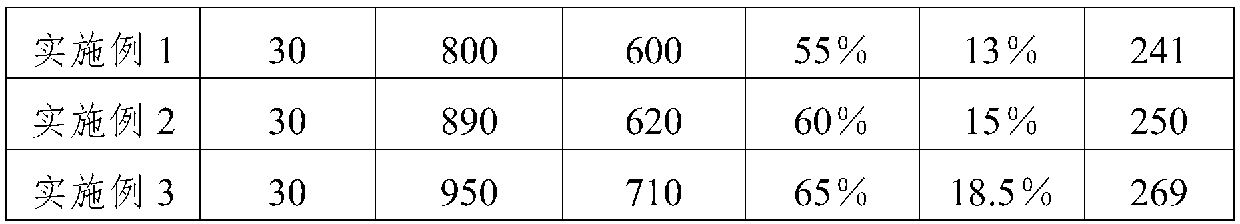

Embodiment 1

[0030] The present invention provides a wind power main shaft forging process, the specific forging steps are as follows:

[0031] S1. Raw material pretreatment: The steps of electric furnace smelting, LF refining and VD vacuum treatment for steel ingots are as follows:

[0032] S1.1. Electric furnace smelting: the furnace wall cluster oxygen lance ultra-high power electric arc furnace is used to strengthen oxygen supply, and carbon powder is injected into the furnace to create foam slag operation to ensure sufficient decarburization amount and decarburization speed;

[0033] S1.2, LF refining: Bottom blowing argon gas stirring during power transmission, using diffusion deoxidizer for diffusion deoxidation;

[0034] S1.3, VD vacuum treatment: Before entering the VD station, remove part of the refining slag to enhance the vacuum degassing effect, reduce slag overflow, and ensure the ladle is clear, so as to obtain steel ingots with low oxygen and high cleanliness;

[0035] S2....

Embodiment 2

[0044] The present invention provides a wind power main shaft forging process, the specific forging steps are as follows:

[0045] S1. Raw material pretreatment: The steps of electric furnace smelting, LF refining and VD vacuum treatment for steel ingots are as follows:

[0046] S1.1. Electric furnace smelting: the furnace wall cluster oxygen lance ultra-high power electric arc furnace is used to strengthen oxygen supply, and carbon powder is injected into the furnace to create foam slag operation to ensure sufficient decarburization amount and decarburization speed;

[0047] S1.2, LF refining: Bottom blowing argon gas stirring during power transmission, using diffusion deoxidizer for diffusion deoxidation;

[0048]S1.3, VD vacuum treatment: Before entering the VD station, remove part of the refining slag to enhance the vacuum degassing effect, reduce slag overflow, and ensure the ladle is clear, so as to obtain steel ingots with low oxygen and high cleanliness;

[0049] S2. ...

Embodiment 3

[0058] The present invention provides a wind power main shaft forging process, the specific forging steps are as follows:

[0059] S1. Raw material pretreatment: The steps of electric furnace smelting, LF refining and VD vacuum treatment for steel ingots are as follows:

[0060] S1.1. Electric furnace smelting: the furnace wall cluster oxygen lance ultra-high power electric arc furnace is used to strengthen oxygen supply, and carbon powder is injected into the furnace to create foam slag operation to ensure sufficient decarburization amount and decarburization speed;

[0061] S1.2, LF refining: Bottom blowing argon gas stirring during power transmission, using diffusion deoxidizer for diffusion deoxidation;

[0062] S1.3, VD vacuum treatment: Before entering the VD station, remove part of the refining slag to enhance the vacuum degassing effect, reduce slag overflow, and ensure the ladle is clear, so as to obtain steel ingots with low oxygen and high cleanliness;

[0063] S2....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com