Polishing device capable of achieving multi-axis switching

A polishing device and polishing wheel technology, which can be applied to grinding drive devices, surface polishing machine tools, grinding/polishing equipment, etc. The effect of polishing efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

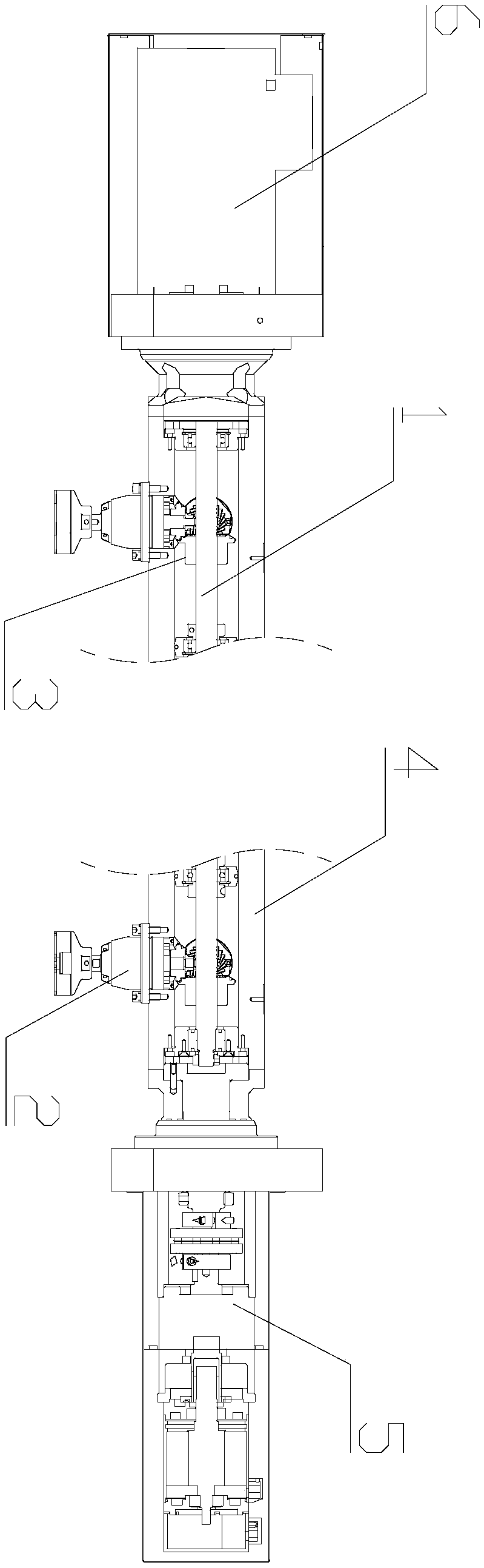

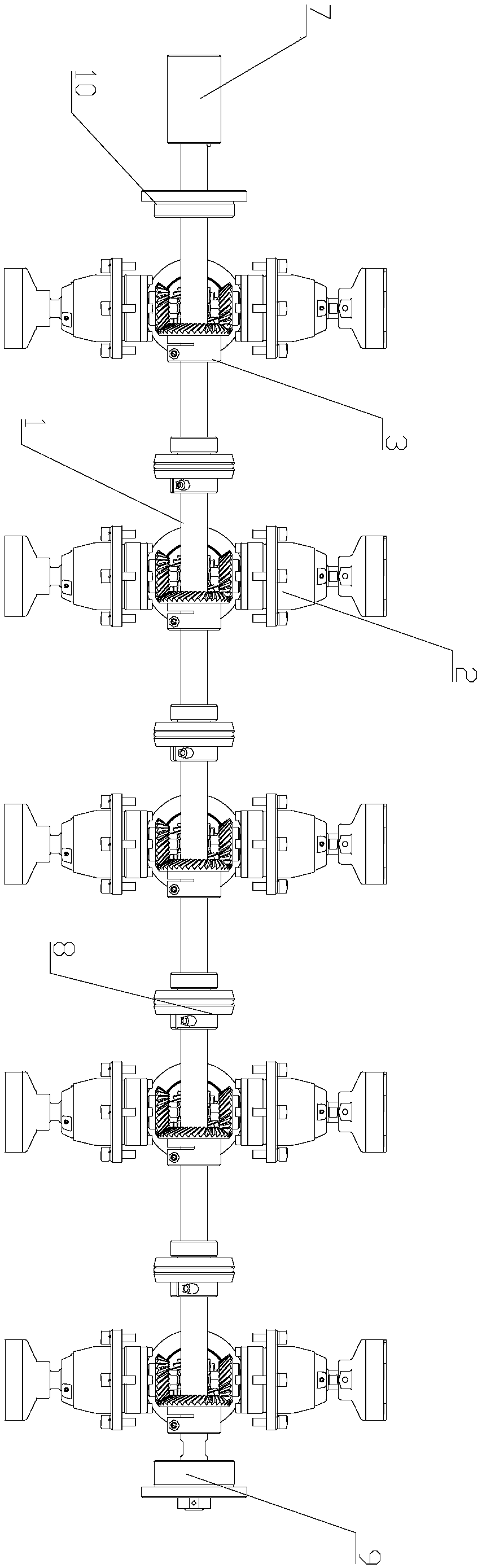

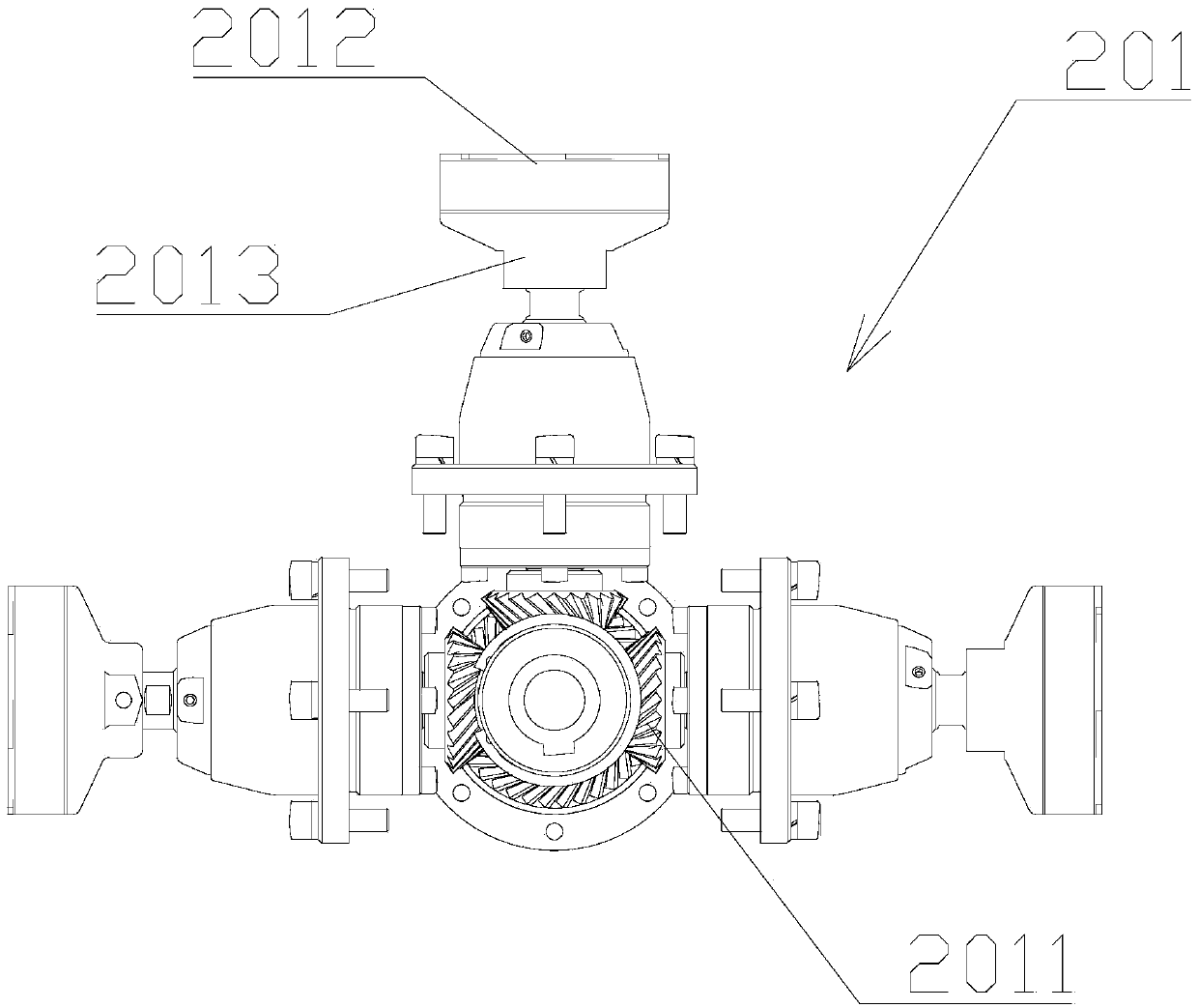

[0030] This embodiment provides a multi-axis switching polishing device, such as Figure 1-2 As shown, the device includes: a transmission shaft 1; a polishing wheel unit 2, the polishing wheel unit includes at least two polishing wheel assemblies 201, and the end of the polishing wheel assembly 201 is provided with a driven gear 2011; the driving gear 3 is sleeved on The transmission shaft 1 is outside, and is engaged with the driven gear 2011; the rotating beam 4, the polishing wheel unit 2 is connected to the rotating beam 4. In this embodiment, the driven gear 2011 is a spiral bevel gear, which has stable transmission, high bearing capacity, wear resistance, and low noise. Through this high-precision gear meshing action, it is further guaranteed that the polishing wheel assembly 201 can operate at a high speed. The beating is small when rotating, and the cutting force of polishing is more uniform, thus ensuring the consistency of polishing effect.

[0031] The models and ...

Embodiment 2

[0039] This embodiment provides a multi-axis switchable polishing device, the structure of which is basically the same as that of Embodiment 1. Specifically, in this embodiment, each polishing wheel unit 2 includes three polishing wheel assemblies 201, three polishing wheel assemblies The 201 is a different model. like image 3 As shown, the driven gears 2011 of the three polishing wheel assemblies 201 are meshed with the driving gear 3, and the revolution driving mechanism 5 drives the rotating beam 4 to rotate, thereby driving the polishing wheel unit 2 to rotate, so that different polishing The wheel assembly 201 rotates to a processing position to meet different processing requirements.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com