Collecting agent for magnesium siliceous phosphorite mixed reverse flotation, preparation method and beneficiation method

A beneficiation method and reverse flotation technology, applied in flotation, solid separation and other directions, can solve the problems of inconvenient operation, high cost, difficulty in obtaining high-quality phosphate concentrate products, etc. The cost of reagents, the effect of simplifying the mixed reverse flotation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

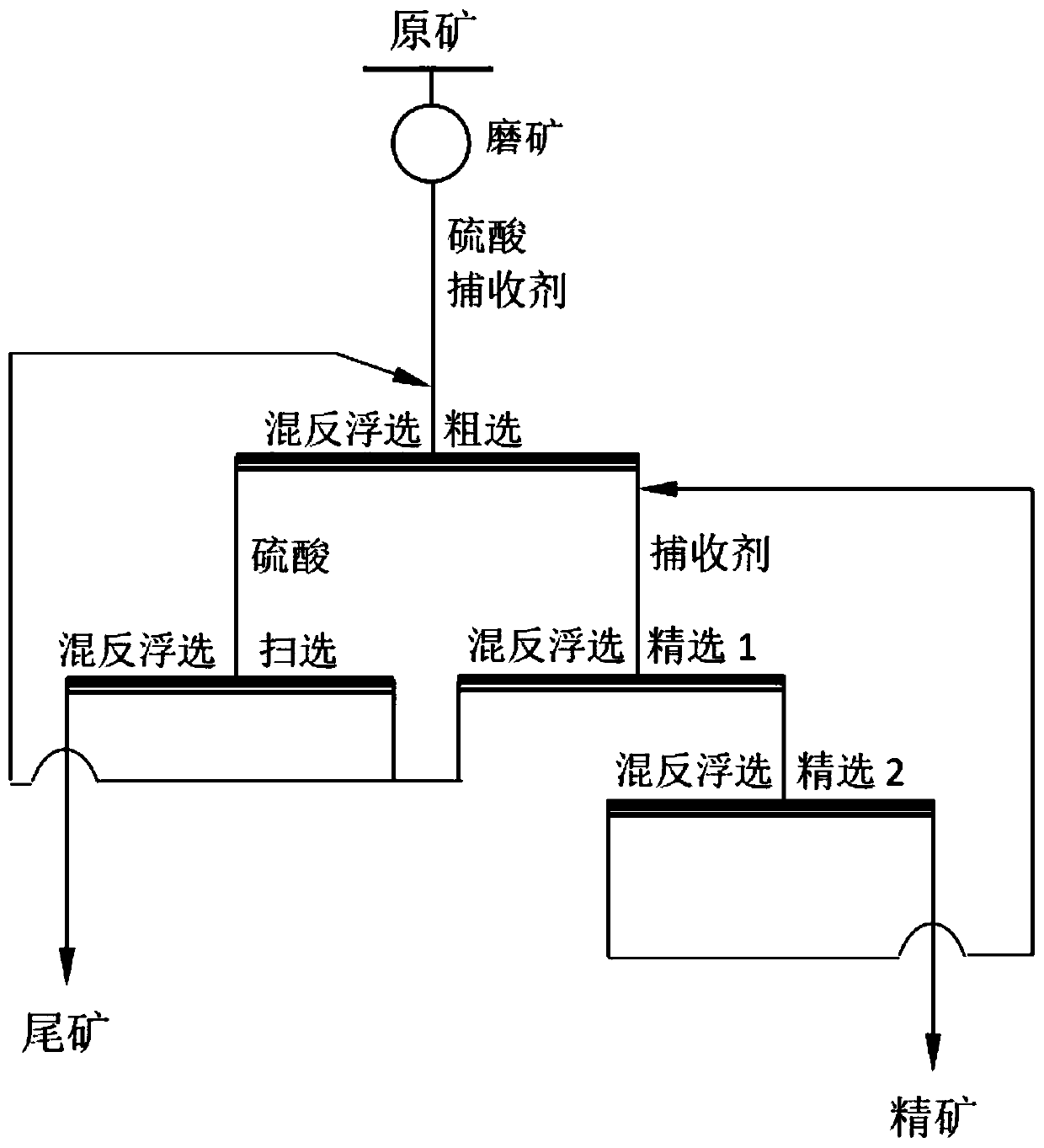

Embodiment 1

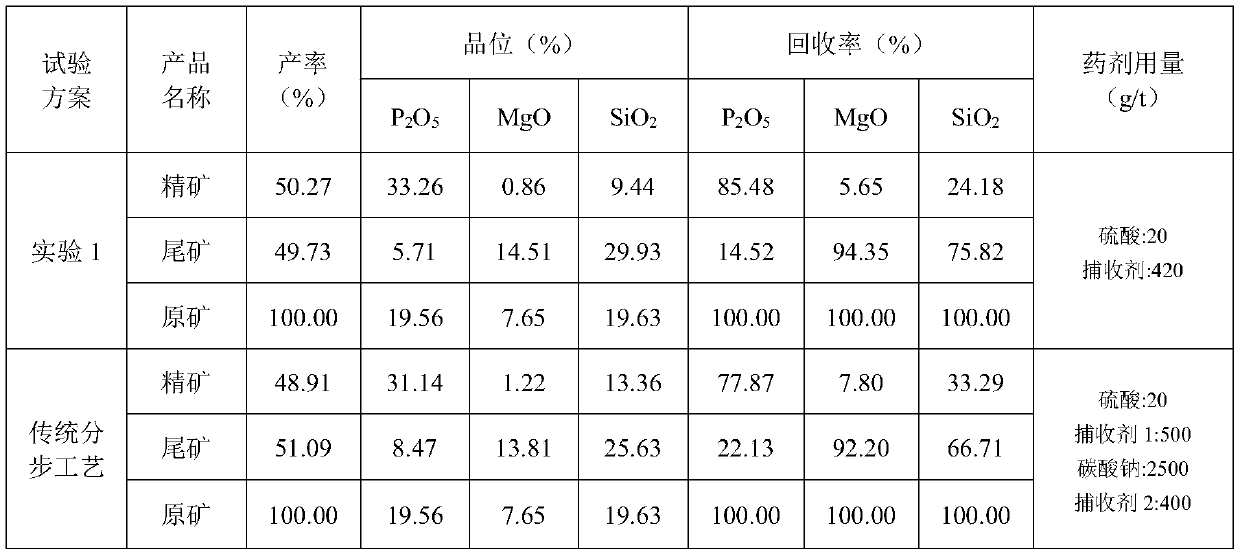

[0035] A kind of beneficiation method of mixed reverse flotation of magnesia siliceous phosphate rock, using magnesia siliceous phosphate rock from a certain place in Sichuan as raw material, P in the raw ore 2 o 5 Content 19.56%, SiO 2 The content of MgO is 19.63%, and the content of MgO is 7.65%. The collector used in ore dressing is prepared by the following method:

[0036] (1) Take raw materials, oxidized paraffin wax soap 30g, kerosene 60g;

[0037] (2) Stir the above-mentioned kerosene that has been weighed under the action of ultrasonic waves and slowly add oxidized paraffin wax soap at the same time, stir and emulsify for 10 minutes to make it fully dissolved and emulsified;

[0038](3) Slowly add 15 g of etheramine after the operation in step (2), continue to stir continuously under the action of ultrasonic waves, and stir and emulsify for 15 minutes to fully dissolve and emulsify;

[0039] (4) Slowly add 2000g of water after step (3), continue to stir continuousl...

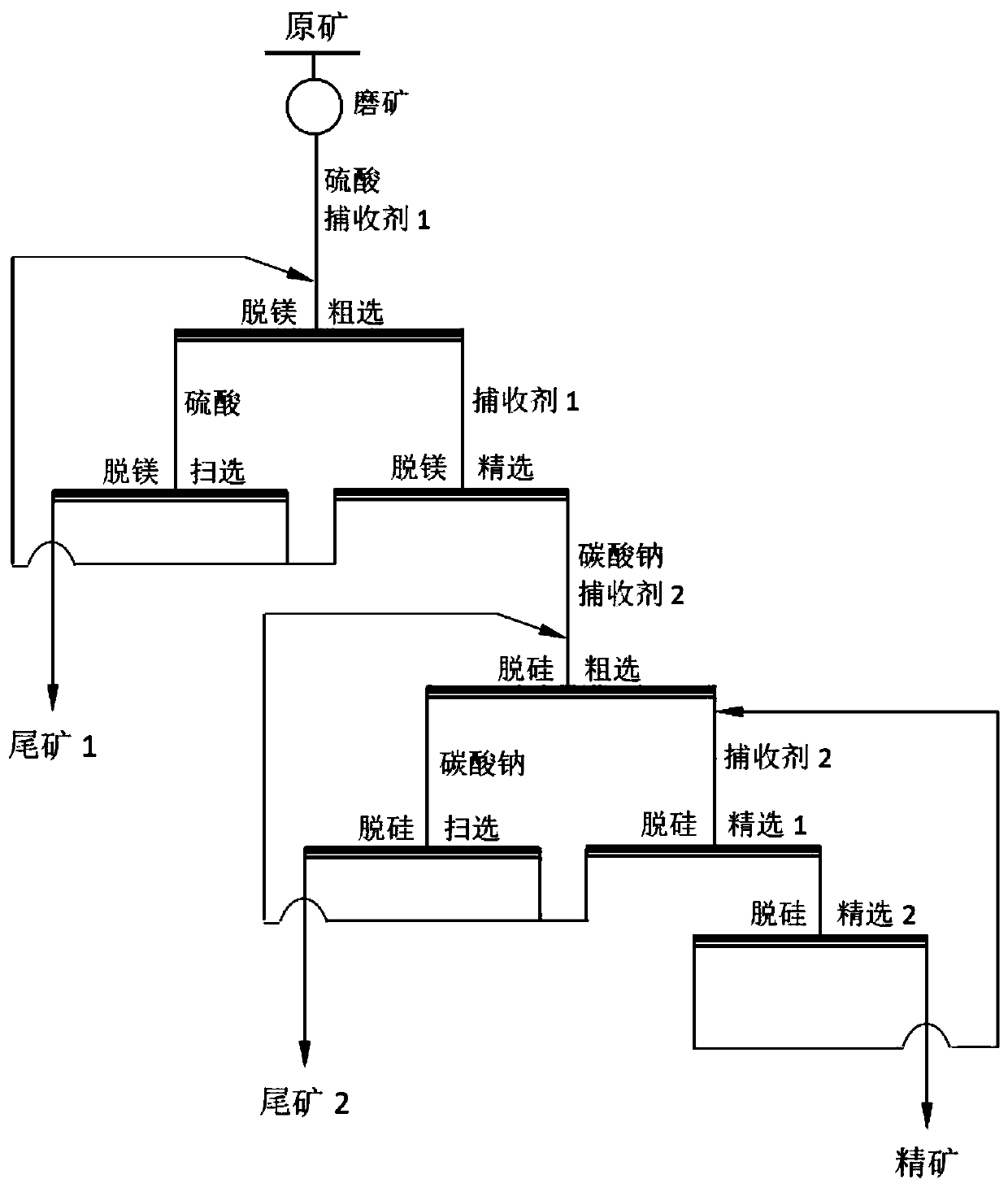

Embodiment 2

[0051] A kind of beneficiation method of mixed reverse flotation of magnesia siliceous phosphate rock, using magnesia siliceous phosphate rock from a certain place in Sichuan as raw material, wherein P 2 o 5 Content 15.64%, SiO 2 The content of MgO is 23.58%, and the MgO content is 9.37%. The gangue mineral collector used in ore dressing is prepared by the following method:

[0052] (1) Take raw materials, oxidized paraffin wax soap 25g, kerosene 50g;

[0053] (2) Stir the above-mentioned kerosene that has been weighed under the action of ultrasonic waves and slowly add oxidized paraffin wax soap at the same time, and stir and emulsify for 15 minutes to make it fully dissolved and emulsified;

[0054] (3) Slowly add 20 g of ether amine after the operation in step (2), continue to stir continuously under the action of ultrasonic waves, and stir and emulsify for 15 minutes to fully dissolve and emulsify;

[0055] (4) Slowly add 2000g of water after the operation in step (3), ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com