A kind of casting equipment for aluminum alloy automobile wheel hub that is easy to demould

A technology for automobile wheel hubs and casting equipment, which is applied in casting molding equipment, metal processing equipment, grinding/polishing equipment, etc. The effect of time spent

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

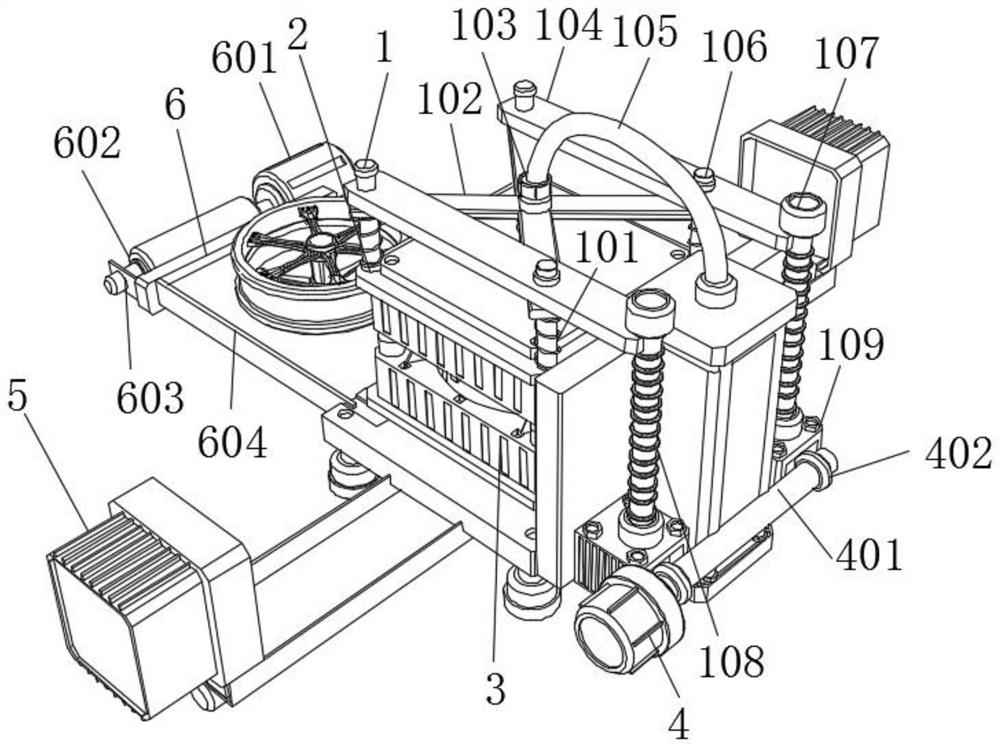

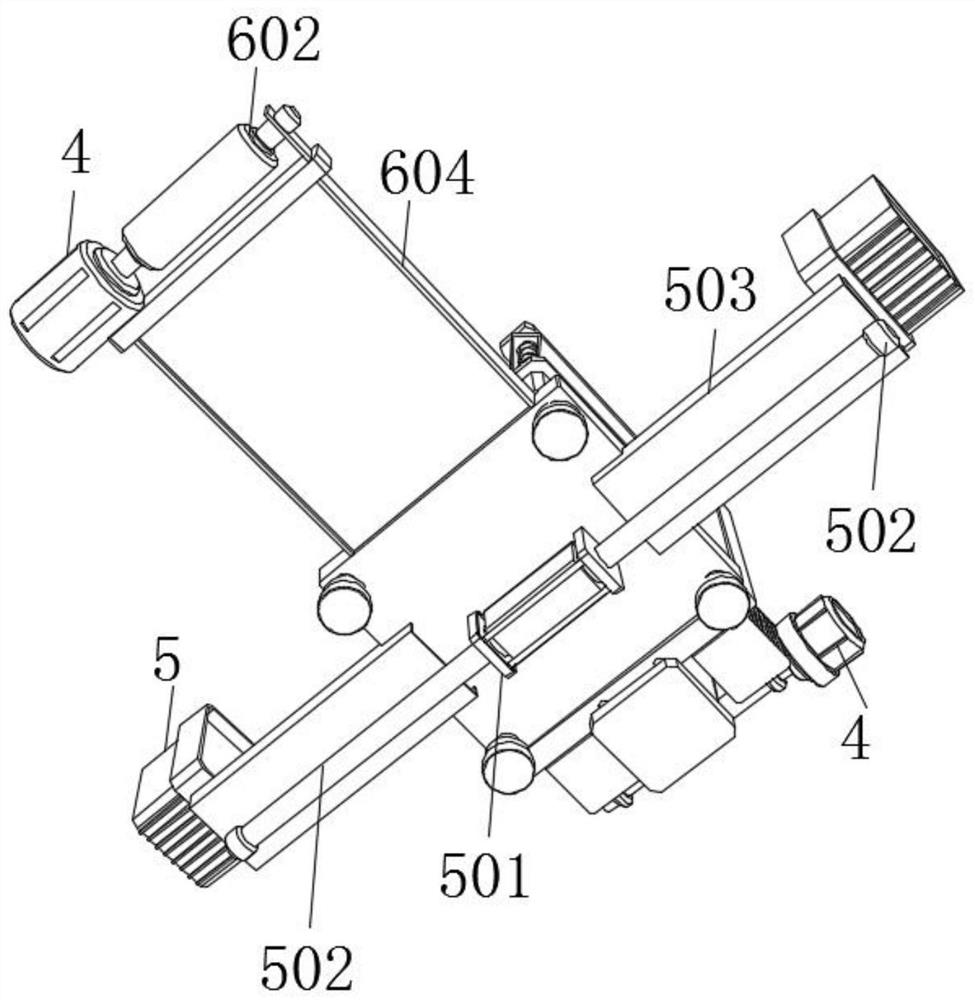

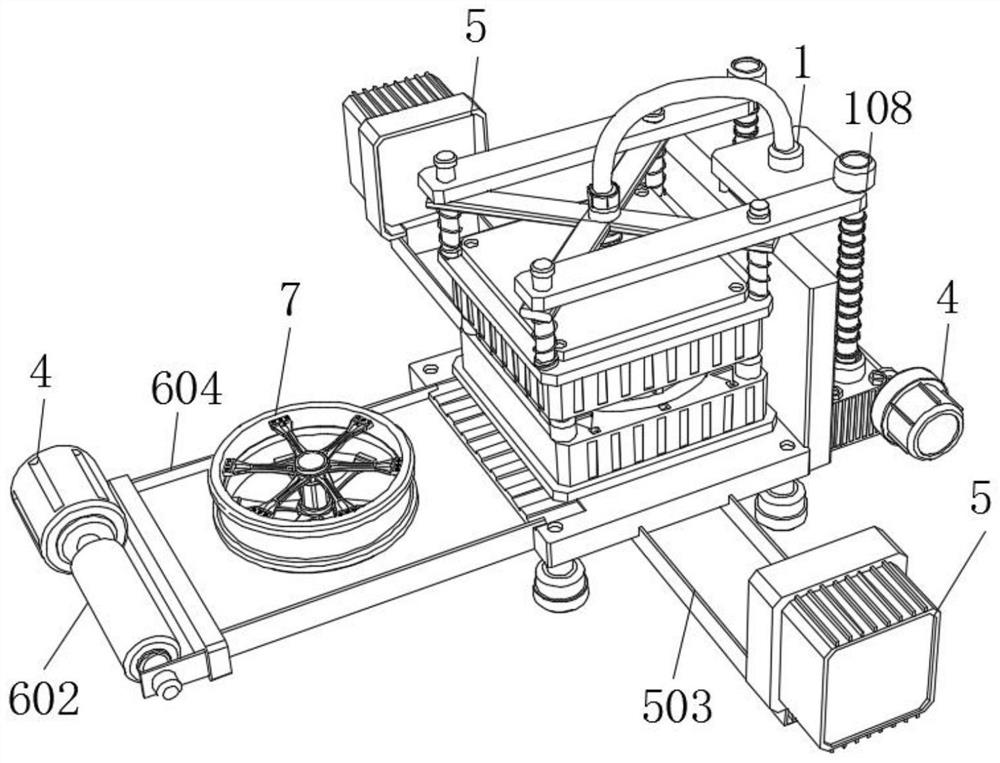

[0030] see Figure 1-7 , the present invention provides the following technical solutions: including a lifting mechanism 1, the bottom end of the lifting mechanism 1 is supported by an upper mold base 2, the bottom of the upper mold base 2 is provided with a matching lower mold base 3, and the lower mold base 3 The bottom of the support pallet is provided with a support pallet, and one side of the support pallet is fixedly equipped with a polishing mechanism 6, and both sides of the bottom of the support pallet are provided with a support base plate 503, through the lifting mechanism 1 provided, the telescopic spring 101, the bracket 102 and The liquid injection port is convenient for injecting high-temperature liquid, and the liquid injection pipe 105 is used to realize the transportation of the liquid, and the guide rod 106, the telescopic spring 101, the bearing 107, the screw rod 108 and the rotating roller 401 are provided to facilitate the driving effect of the motor 4. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com