Quick response hydraulic control valve of high-pressure common rail fuel injector

A hydraulic control valve, fast-response technology, applied in machine/engine, fuel injection device, engine components, etc., can solve the problems of limited practical effect, inability to control the delay of opening and closing of the injector at the same time, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

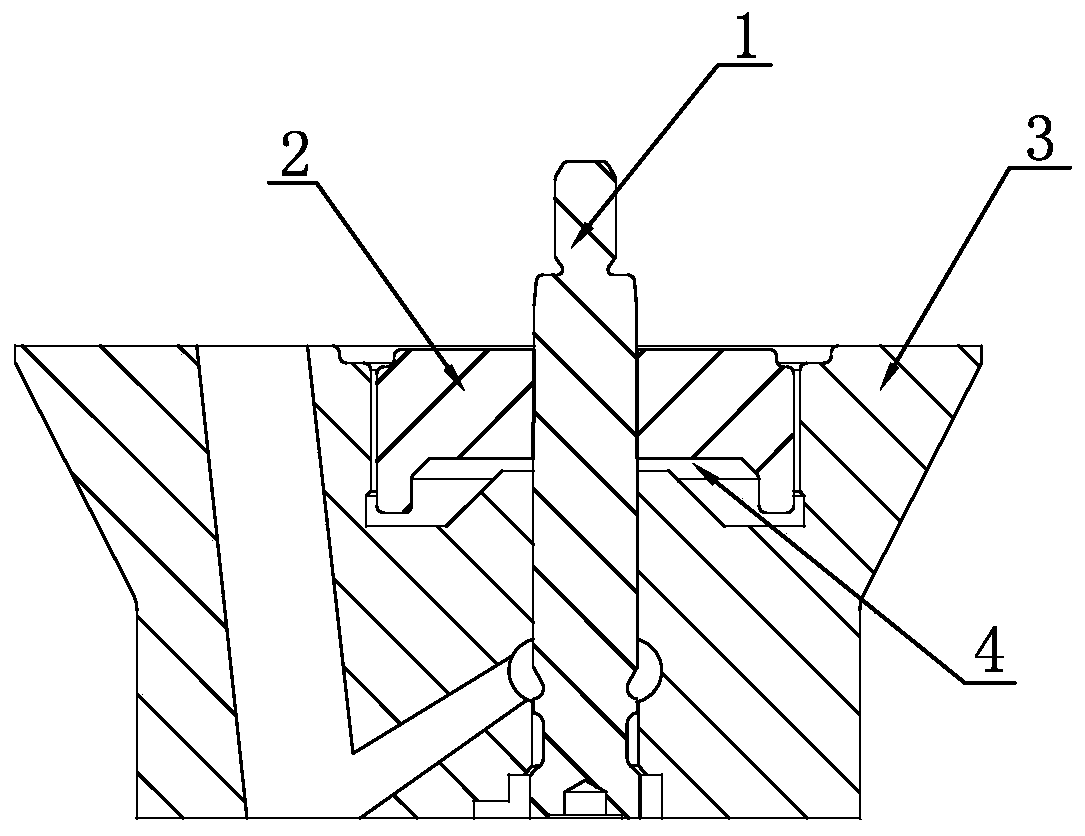

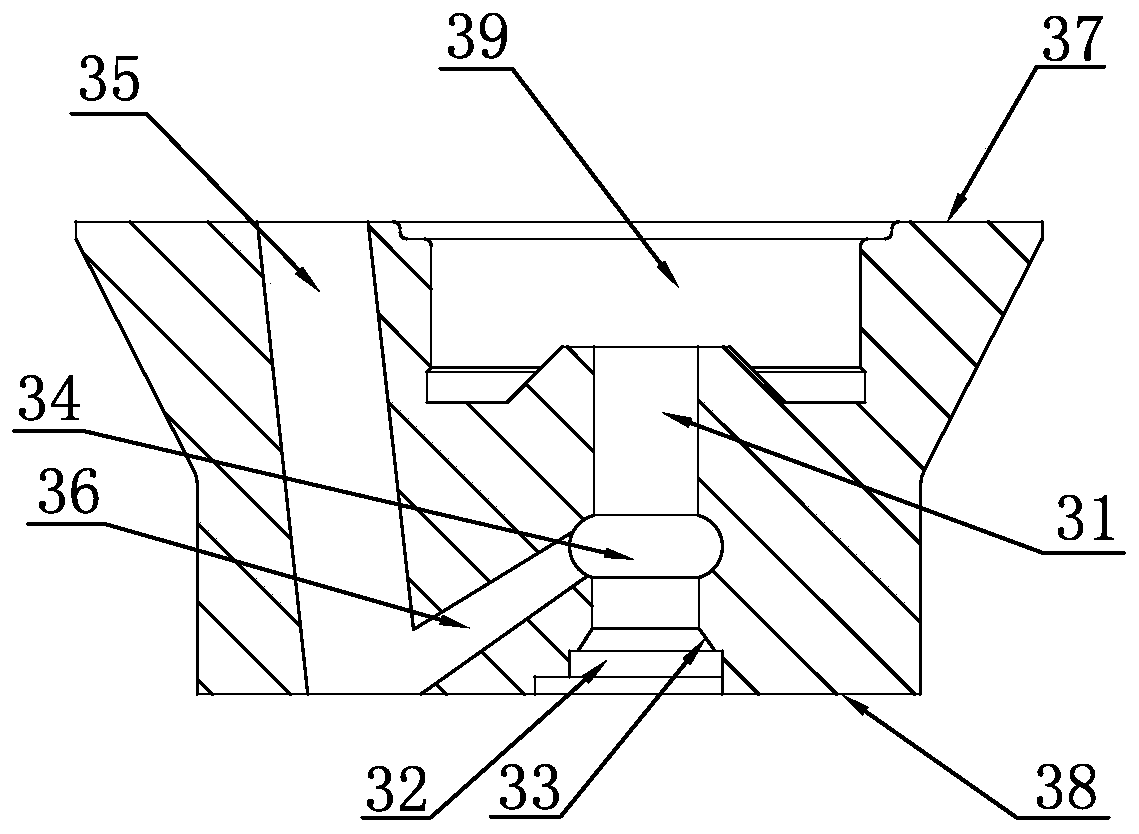

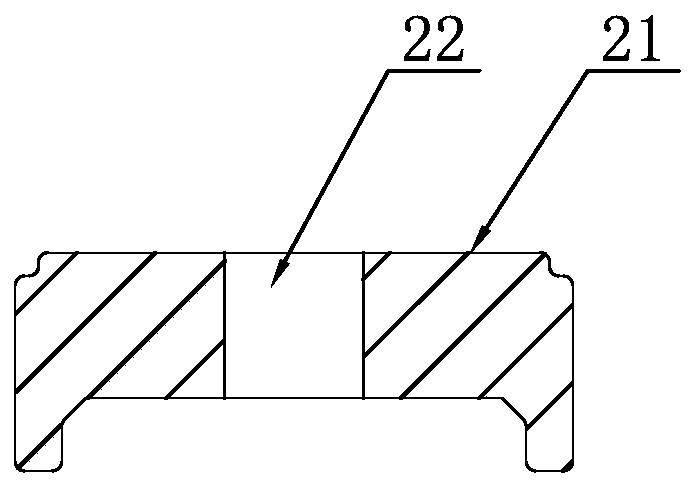

Embodiment 1

[0020] A quick-response hydraulic control valve for a high-pressure common rail fuel injector, characterized in that it includes a valve core post 1, an armature plate 2 and a control valve seat 3; the valve core post includes a spring limit section 11, a guide post 12, Intermediate sealing section 13, concave space 14, oil storage groove 15, end surface groove 16, guide rod lower end surface 17, oil storage groove tapered surface 18, axial limit post 19, intermediate sealing section 13, concave space 14 and The oil storage grooves 15 are all arranged on the guide column 12, the axial limit column 19 is arranged at the lower end of the guide column 12, the spring limit section 11 is arranged at the upper end of the guide column 12, and the end surface groove 16 is arranged on the lower end surface of the guide rod At the center of 17, the conical surface 18 of the oil storage groove is arranged on the lower side of the oil storage groove 15, and the guide column 12 of the valve...

Embodiment 2

[0024] Embodiment 2: The difference from Embodiment 1 is that the diameter of the axial limit post 19 is 0.2-2 mm larger than the diameter of the valve core guide hole 31 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com