Eight-core optical fiber multiplexing and demultiplexing device and its preparation method

A demultiplexer and core optical fiber technology, which is applied in the field of optical transmission devices, can solve the problems that the natural arrangement of optical fiber bundles cannot be guaranteed, and achieve the effect of low overall loss, reduction of loss and crosstalk between cores

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

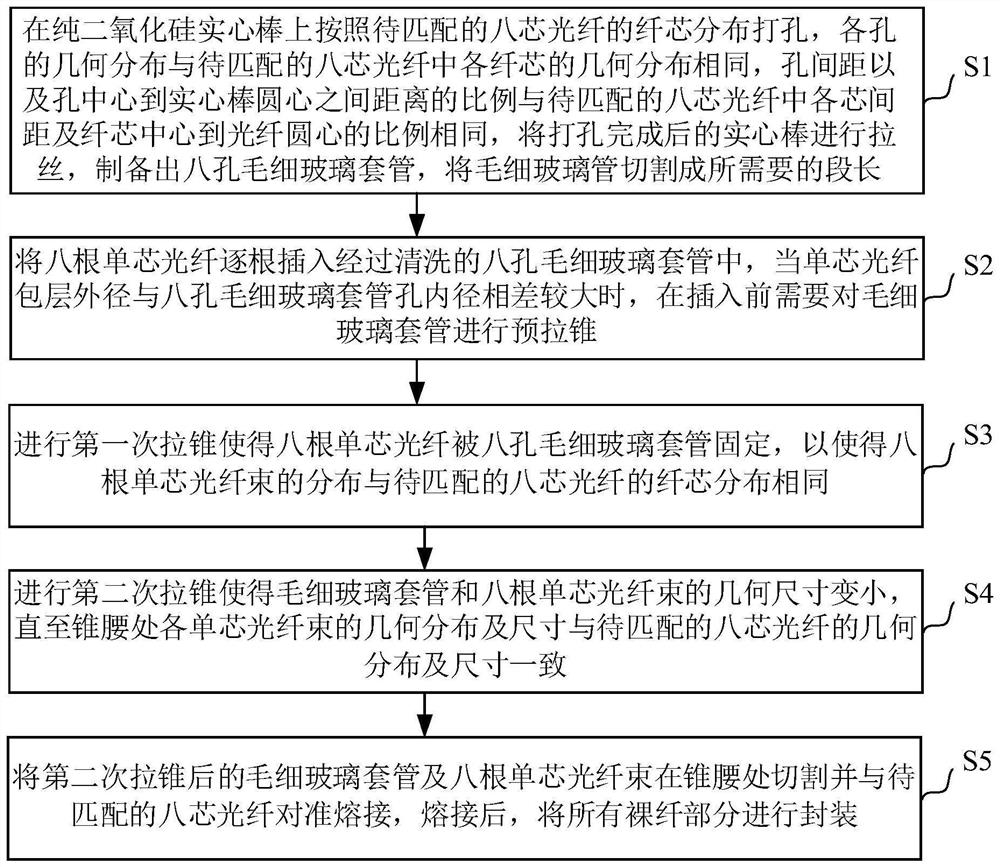

[0042] Such as figure 1 Shown is a schematic flow diagram of a method for preparing an eight-core optical fiber multiplexing and demultiplexing device provided by an embodiment of the present invention, including the following steps:

[0043] S1: Holes are drilled on the pure silica solid rod according to the core distribution of the eight-core optical fiber to be matched, and the geometric distribution of each hole is the same as that of each core in the eight-core optical fiber to be matched, which is an equal proportional amplification relationship , the hole spacing and the ratio of the distance between the center of the hole and the center of the solid rod are the same as the distance between the cores of the eight-core optical fiber to be matched and the ratio of the center of the fiber core to the center of the fiber. Eight-hole capillary glass sleeve, cut the capillary glass tube into the required length;

[0044] In the embodiment of the present invention, the eight ...

Embodiment 1

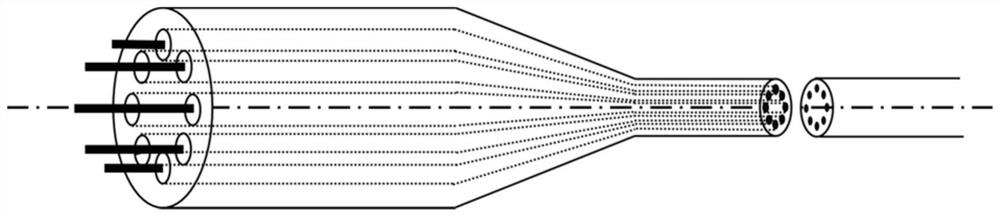

[0056] Example 1: Preparation of an annular eight-core optical fiber multiplexing and demultiplexing device

[0057] The core spacing a of the circular eight-core fiber is 31±0.5um, the distance b from the center of each core to the center of the fiber is about 40.5±0.5um, and the outer diameter of the fiber cladding is 125±0.7um.

[0058] Preparation of the annular eight-hole capillary glass cannula:

[0059] Holes are drilled on a pure silica solid rod with a diameter of D = 25-30 mm according to the arrangement of the circular eight-core optical fiber, such as Figure 4 shown. Hole spacing A=6.8±0.1mm, distance B=8.9±0.1mm between the center of the hole and the center of the solid rod. The ratio of A to B is the same as the ratio of a to b. The hole diameter d=5mm. After the drilling is completed, wire drawing is carried out on the wire drawing tower, and the glass sleeve containing eight holes is drawn into an annular eight-hole capillary glass tube with an outer diame...

Embodiment 2

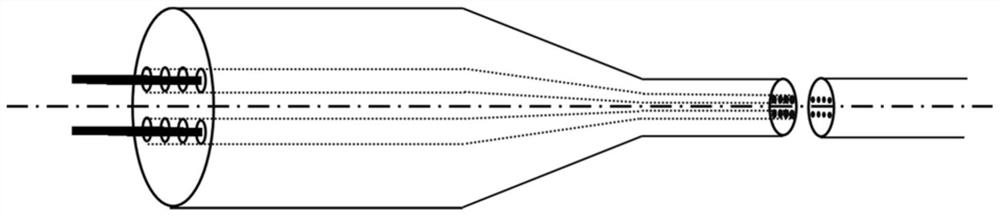

[0067] Example 2: Preparation of rectangular eight-core optical fiber multiplexing and demultiplexing device

[0068] The transverse core spacing a of the rectangular eight-core optical fiber is 32±0.5um, the longitudinal core spacing b is 40±0.5um, and the outer diameter of the fiber cladding is 150±1um.

[0069] Preparation of rectangular eight-hole capillary glass cannula:

[0070] Holes are punched on a pure silica solid rod with a diameter of D=75-80mm according to the arrangement of rectangular eight-core optical fibers, such as Figure 4 shown. Horizontal hole spacing A=14.9±0.2mm, longitudinal hole spacing B=18.6±0.2mm. The ratio of A to B is the same as the ratio of a to b. The hole diameter d=12mm. After the drilling is completed, wire drawing is carried out on the wire drawing tower, and the glass sleeve containing eight holes is drawn into a rectangular eight-hole capillary glass tube with an outer diameter of 620-670um and an inner diameter of about 100um. Du...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com