Truck radial tire body structure

A radial tire and carcass structure technology, which is applied to tire parts, reinforcement layers of pneumatic tires, vehicle components, etc., can solve problems affecting tire service life, affecting the production environment, poor adhesion, etc., and achieve improved retreading performance , Reduce consumption, reduce heat generation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

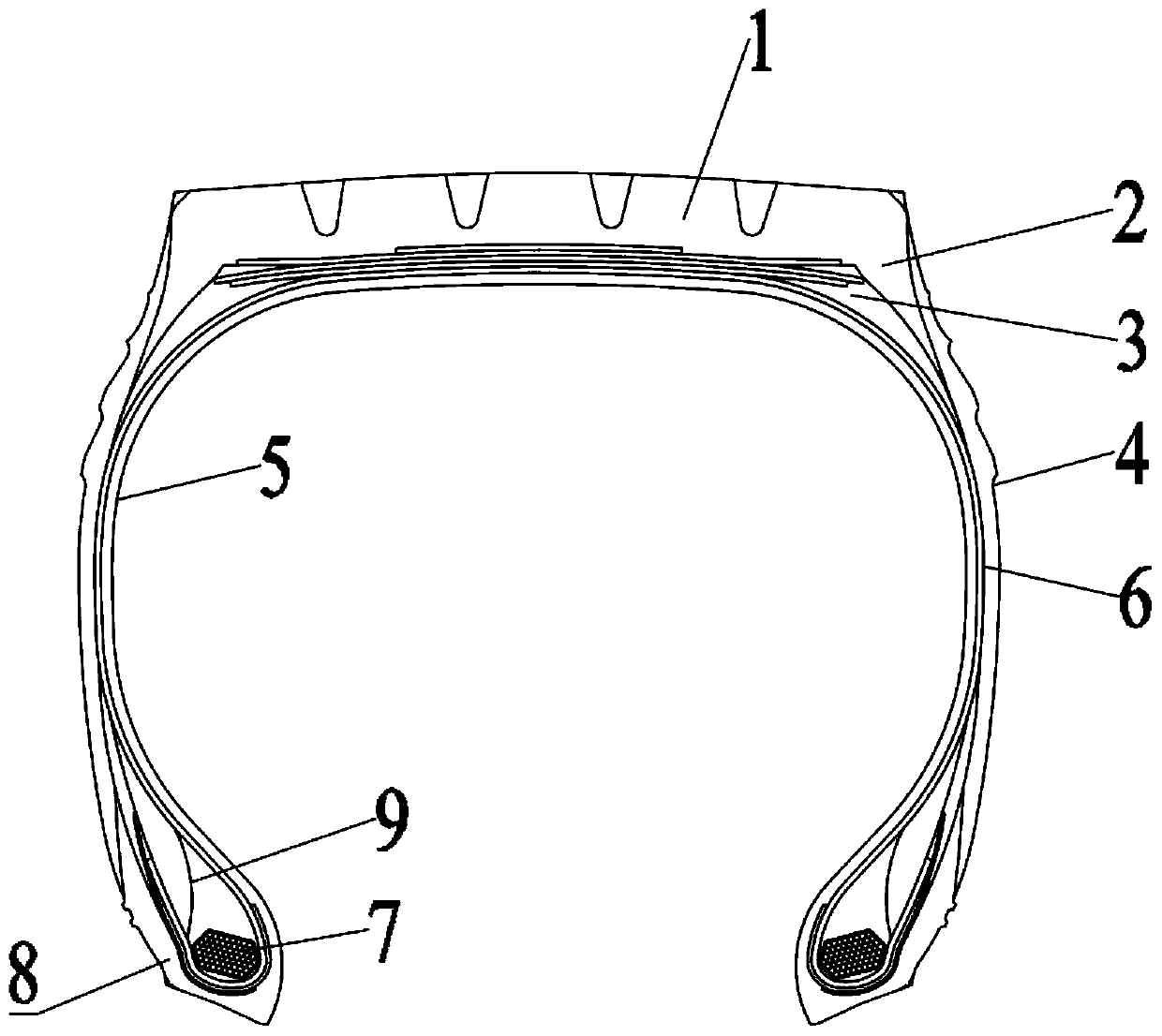

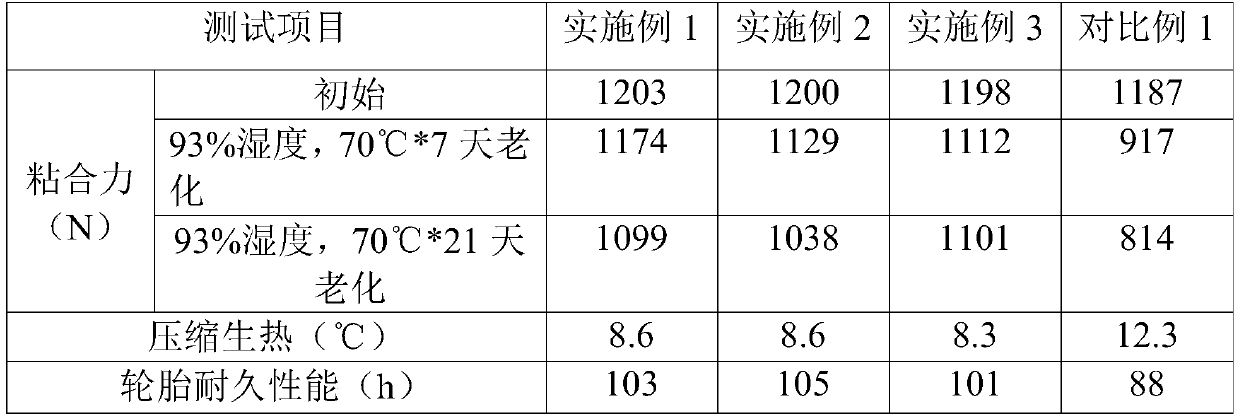

[0015] A carcass structure of a load radial tire. The tire includes a crown portion 1, a base portion 2 located under the crown and a sidewall 4 below the two shoulders 3. An inner liner 5 is arranged on the inner side of the tire. The inner liner There is a layer of carcass 6 on the outer side of the carcass 6, and the two sides of the carcass 6 are wrapped around the bead ring 7 and placed in the triangular part 9 to form the bead part 8. The carcass is made of three-phase alloy steel cords and cobalt-free tires. The carcass rubber is combined by calendering. The coating of the steel cord contains 64.5% Cu, 31.5% Zn and 4% Co. The carcass compound formula contains 100 parts by weight of natural rubber and 53 parts by weight of carbon black N326. Zinc oxide is 8 parts by weight, anti-aging agent is 2.5 parts by weight, insoluble sulfur OT20 is 5.0 parts by weight, accelerator NS is 0.4 parts by weight, and anti-scorch agent CTP is not added.

[0016] The density of three-phas...

Embodiment 2

[0018] A carcass structure of a load radial tire. The tire includes a crown portion 1, a base portion 2 located under the crown and a sidewall 4 below the two shoulders 3. An inner liner 5 is arranged on the inner side of the tire. The inner liner There is a layer of carcass 6 on the outer side of the carcass 6, and the two sides of the carcass 6 are wrapped around the bead ring 7 and placed in the triangular part 9 to form the bead part 8. The carcass is made of three-phase alloy steel cords and cobalt-free tires. The carcass rubber is combined by calendering. The coating of the steel cord contains 67% Cu, 29% Zn and 4% Co. The carcass compound formula contains 100 parts by weight of natural rubber and 55 parts by weight of carbon black N326. 9 parts by weight of zinc oxide, 3.0 parts by weight of anti-aging agent, 6.0 parts by weight of insoluble sulfur OT20, 0.5 parts by weight of accelerator NS, and 0.1 part by weight of anti-scorch agent CTP.

[0019] The density of three...

Embodiment 3

[0021] A carcass structure of a load radial tire. The tire includes a crown portion 1, a base portion 2 located under the crown and a sidewall 4 below the two shoulders 3. An inner liner 5 is arranged on the inner side of the tire. The inner liner There is a layer of carcass 6 on the outer side of the carcass 6, and the two sides of the carcass 6 are wrapped around the bead ring 7 and placed in the triangular part 9 to form the bead part 8. The carcass is made of three-phase alloy steel cords and cobalt-free tires. The carcass rubber is combined by calendering. The coating of the steel cord contains 69.5% Cu, 26.5% Zn and 4% Co. The formula of the carcass rubber contains 100 parts by weight of natural rubber and 57 parts by weight of carbon black N326. 10 parts by weight of zinc oxide, 3.5 parts by weight of anti-aging agent, 7.0 parts by weight of insoluble sulfur OT20, 0.6 parts by weight of accelerator NS, and 0.2 parts by weight of anti-scorch agent CTP.

[0022] The densi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com