Modified rock wool product and preparation method thereof

A cotton product, modified technology, applied in the direction of glass manufacturing equipment, manufacturing tools, etc., can solve the problems of increasing construction difficulty and construction cost, difficulty in meeting building insulation standards, increasing the thickness of insulation layer, etc., to achieve good insulation effect and improve Thermal performance, quality improvement effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0019] In the present invention, the rock wool and the modifying agent are synchronously compounded on the existing rock wool product production line to produce the modified rock wool product. The preparation process is as follows:

[0020] (1) Preparation of rock wool yarn: the raw materials basalt, slag, dolomite and coke are loaded into the heating furnace according to the ratio of 34:10:16:19 by weight, and the raw materials are melted into magma by high-temperature oxygen-enriched combustion. The magma is made into rock wool yarn under the high-speed rotation of the four-roller centrifuge and the high-pressure blown away wind. During the blowing process, the phenolic resin glue is evenly sprayed on the rock wool yarn. 10% of the total weight of the board, the solid content of phenolic resin is 10%. The rock wool yarn with phenolic resin glue enters the cotton collection chamber under the action of high-pressure blown away wind.

[0021] ⑵Preparation of rock wool bundles...

Embodiment 2

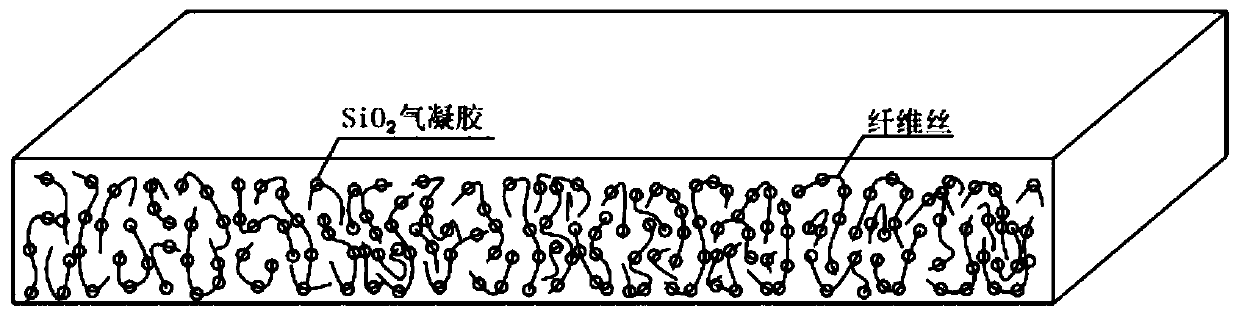

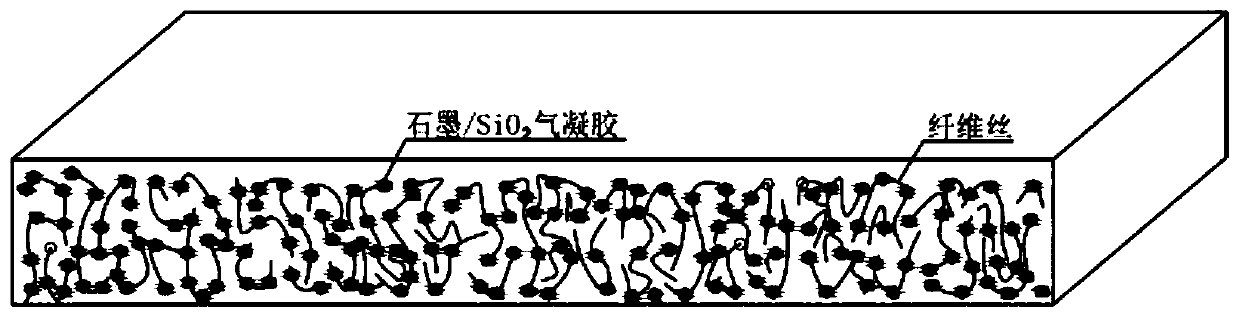

[0025] Change the modifier in step (2) to SiO 2 Aerogel, Graphite-SiO 2 Airgel composites. SiO 2 The amount of airgel added is 6% of the mass of the modified rock wool product, graphite-SiO 2 The addition amount of the airgel composite is 6% of the quality of the modified rock wool product, other steps and process conditions are the same as in Example 1, and the modified agent is SiO 2 Airgel 2 # Modified rock wool products and modifiers are graphite-SiO 2 Airgel Composite 3 # Modified rock wool products.

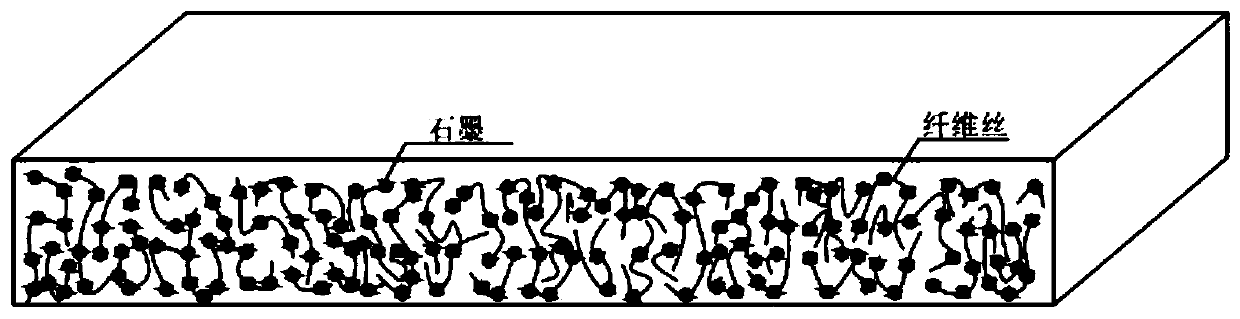

[0026] Such as figure 2 shown, 2 # Modified rock wool product 1 is prepared from rock wool yarn 4, which contains modified substance SiO 2 Airgel5. Such as image 3 shown, 3 # Modified rock wool product 3 is prepared from rock wool yarn 4, which contains modified substance graphite-SiO 2 Aerogel7.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com