Corrosion-resistant low-smoke halogen-free flame-retardant polyolefin cable material and preparation method thereof

A polyolefin cable material and corrosion-resistant technology, which is applied in the field of cable materials, can solve problems such as instability, great influence on the mechanical properties of cable materials, and impact on service life, and achieve enhanced interface effects, improved mechanical properties, and good corrosion resistance performance effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

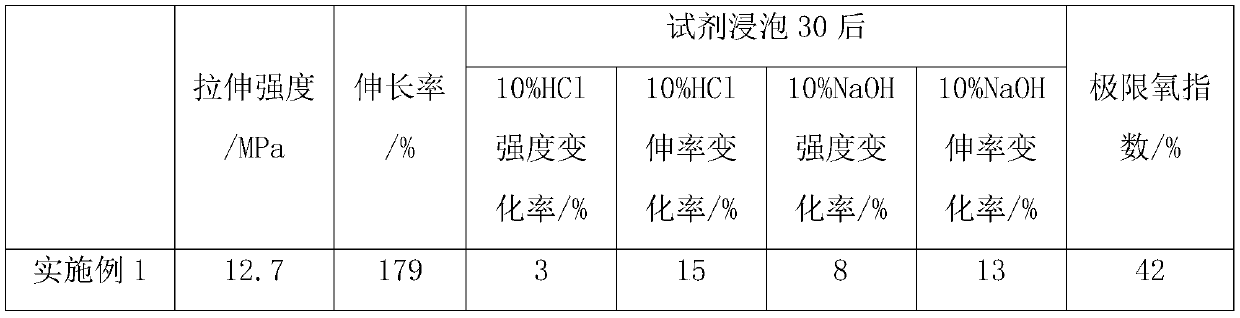

Embodiment 1

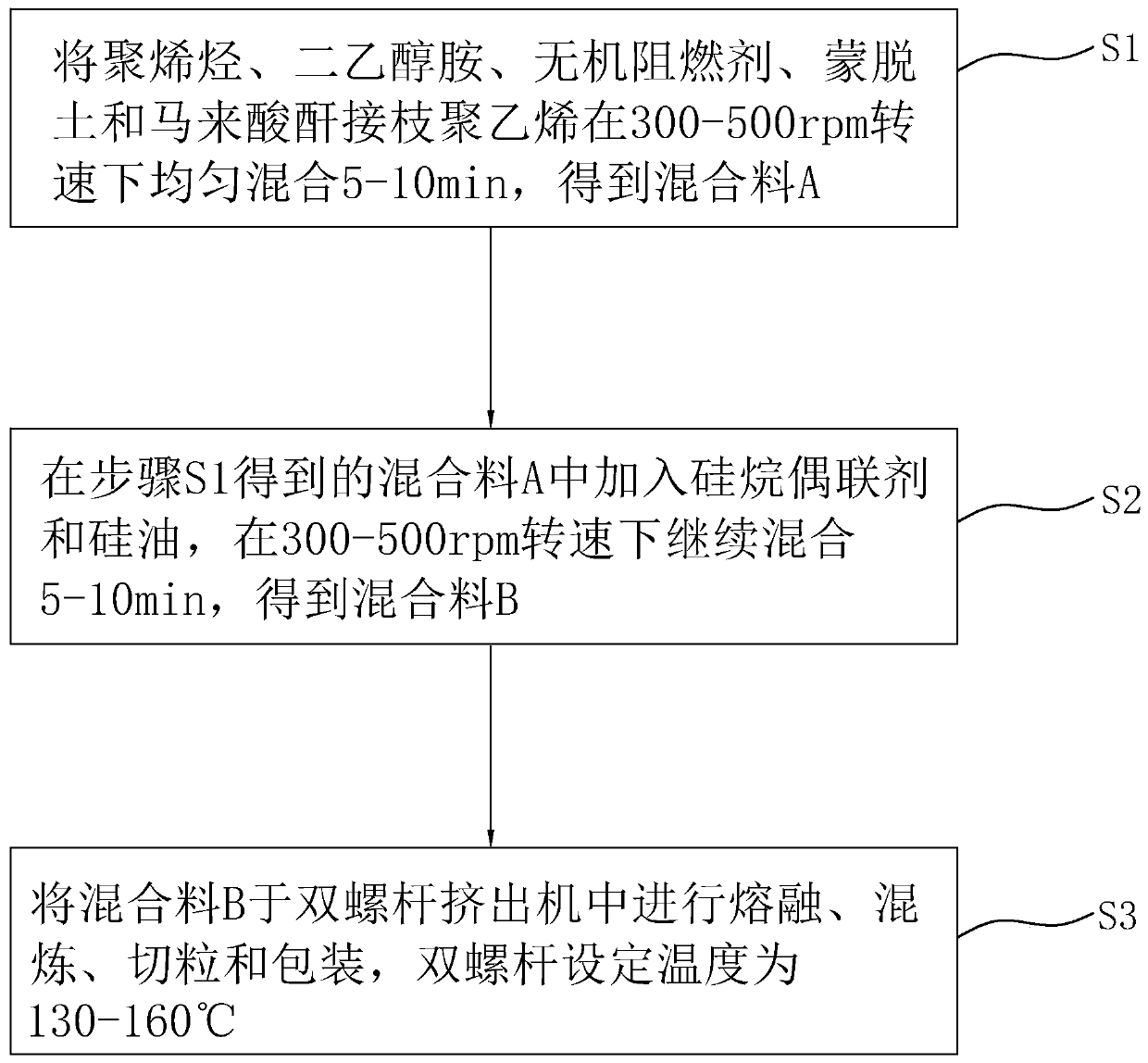

[0051] Embodiment 1: as figure 1, a corrosion-resistant low-smoke halogen-free flame-retardant polyolefin cable material, the components and their corresponding parts by weight are shown in Table 1, and are prepared through the following steps:

[0052] S1, uniformly mixing polyolefin, diethanolamine, inorganic flame retardant, montmorillonite and maleic anhydride grafted polyethylene at a speed of 300 rpm for 10 minutes to obtain a mixture A;

[0053] S2, add silane coupling agent and silicone oil to the mixture A obtained in step S1, and continue mixing at 300 rpm for 10 minutes to obtain mixture B;

[0054] S3, melting, kneading, pelletizing and packaging the compound B in the twin-screw extruder, and the set temperatures of each section of the twin-screw are 130°C, 140°C, 140°C, 140°C, 150°C, 150°C , 150°C, 160°C, and the screw speed during extrusion is 200rpm.

[0055] In this embodiment, magnesium hydroxide with an average particle size of 1.8 μm is used as the inorgan...

Embodiment 2-6

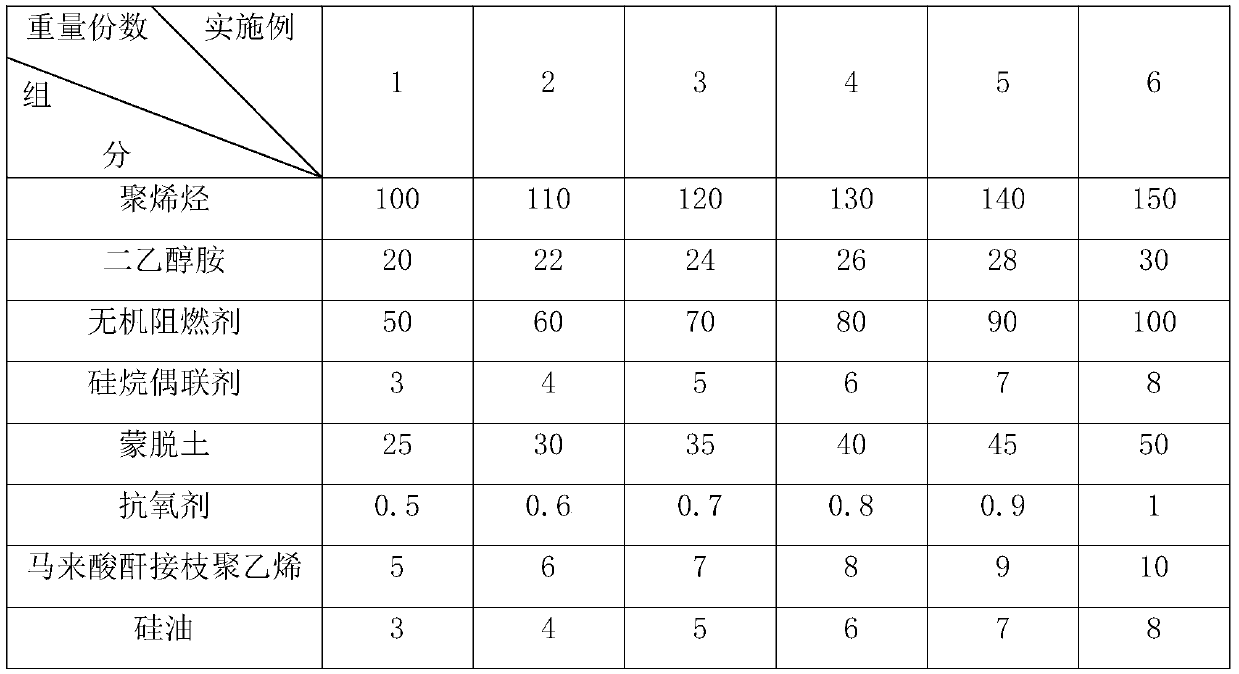

[0056] Example 2-6: A corrosion-resistant, low-smoke, halogen-free, flame-retardant polyolefin cable material. The difference from Example 1 lies in that the components and their corresponding parts by weight are shown in Table 1.

[0057] Each component and parts by weight thereof in table 1 embodiment 1-6

[0058]

Embodiment 7

[0059] Example 7: A corrosion-resistant, low-smoke, halogen-free, flame-retardant polyolefin cable material, which differs from Example 1 in that it is prepared through the following steps:

[0060] S1, uniformly mixing polyolefin, diethanolamine, inorganic flame retardant, montmorillonite and maleic anhydride grafted polyethylene at a speed of 500 rpm for 5 minutes to obtain a mixture A;

[0061] S2, add silane coupling agent and silicone oil to the mixture A obtained in step S1, and continue mixing at 500 rpm for 5 minutes to obtain mixture B;

[0062] S3, melting, kneading, pelletizing and packaging the compound B in the twin-screw extruder, and the set temperatures of each section of the twin-screw are 130°C, 140°C, 140°C, 140°C, 150°C, 150°C , 150°C, 160°C, and the screw speed during extrusion is 200rpm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| The average particle size | aaaaa | aaaaa |

| The average particle size | aaaaa | aaaaa |

| The average particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com