AFM probe capable of being used for quantitative measurement, modification method and application of AFM probe

A technology for quantitative measurement and modification methods, which is applied in the fields of nanomechanics and experimental mechanics, and can solve problems such as affecting measurement accuracy, seeing nanoparticles, and increasing the uncertainty of probe consumption, achieving a wide range of applications and simple operation steps. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The specific embodiments of the present invention will be described in detail below in conjunction with the technical solutions and accompanying drawings.

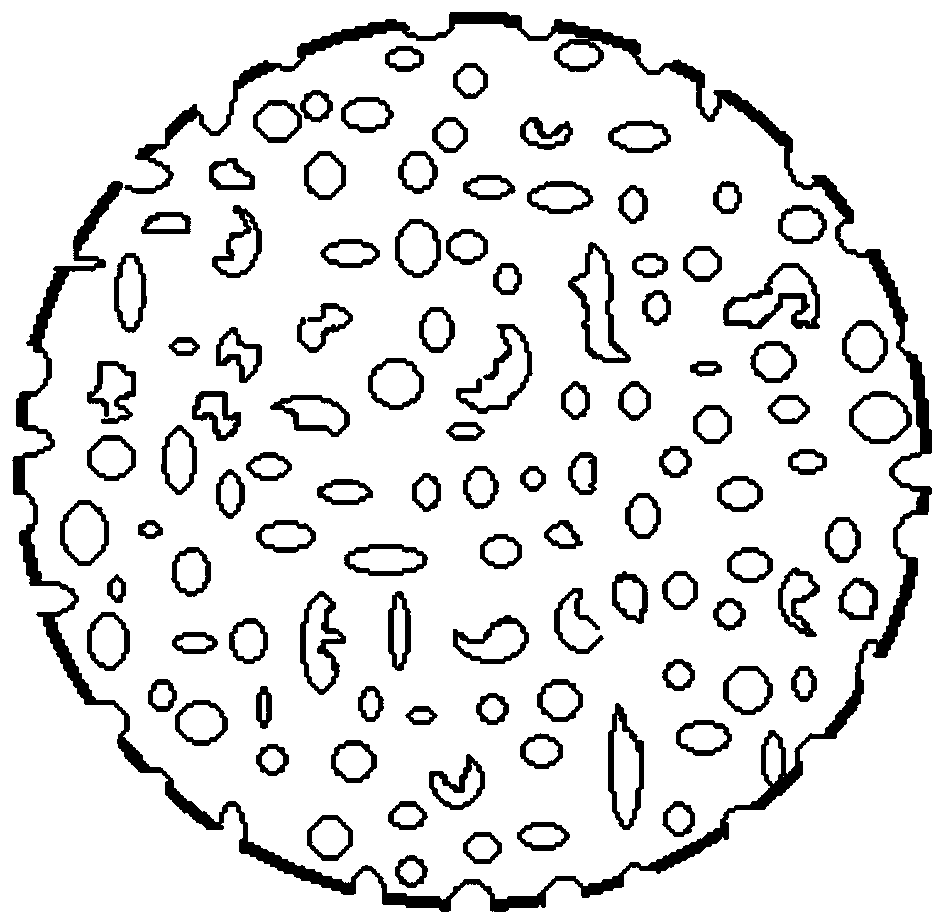

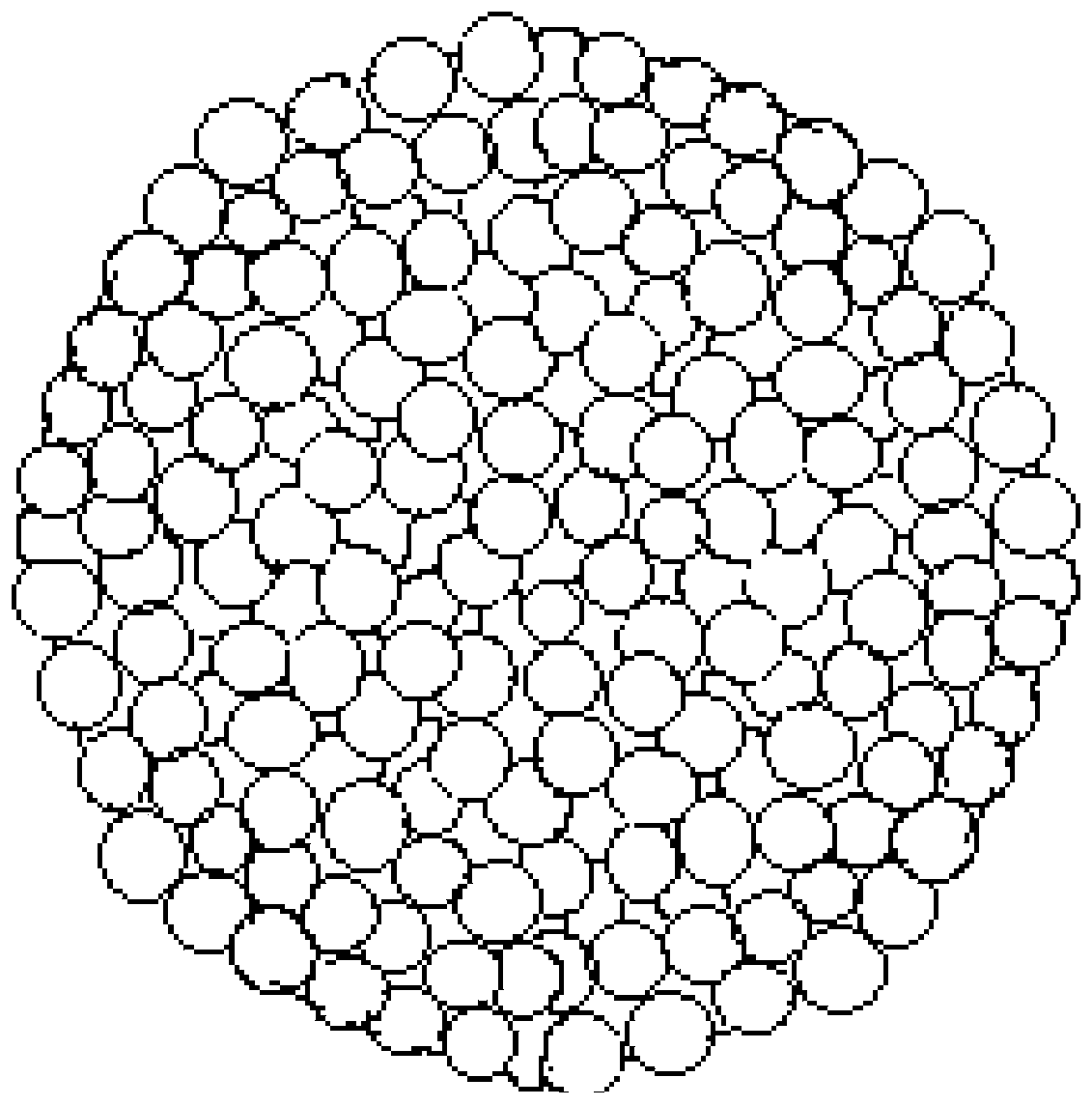

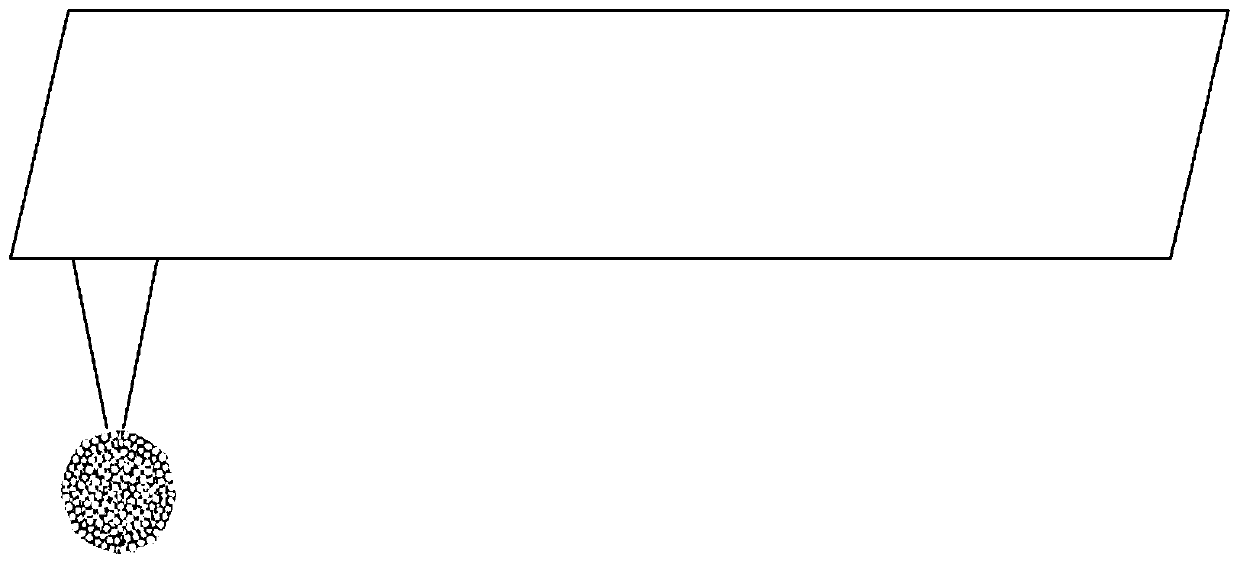

[0028] An AFM probe that can be used for quantitative measurement. The specific structure of the probe is as follows: micron-sized balls are attached to the tip of the AFM probe, and a large number of amorphous concave-convex structures are randomly distributed on the surface of the micron-sized balls, forming a rough On the surface, the nanoparticles are evenly attached to the rough surface of the pellet. The roughness of the rough surface is at the nanometer level, and the peak and valley values of the rough surface are smaller than the size of the nanoparticles to be modified.

[0029] A method for modifying an AFM probe for quantitative measurement, wherein the needle tip of the AFM probe is modified with carbon microspheres whose surface uniformly adsorbs magnetic nanoparticles, and the method for modifying t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Concentration | aaaaa | aaaaa |

| Size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com