Design method of continuous casting billet solidification tail end traveling wave electromagnetic stirring

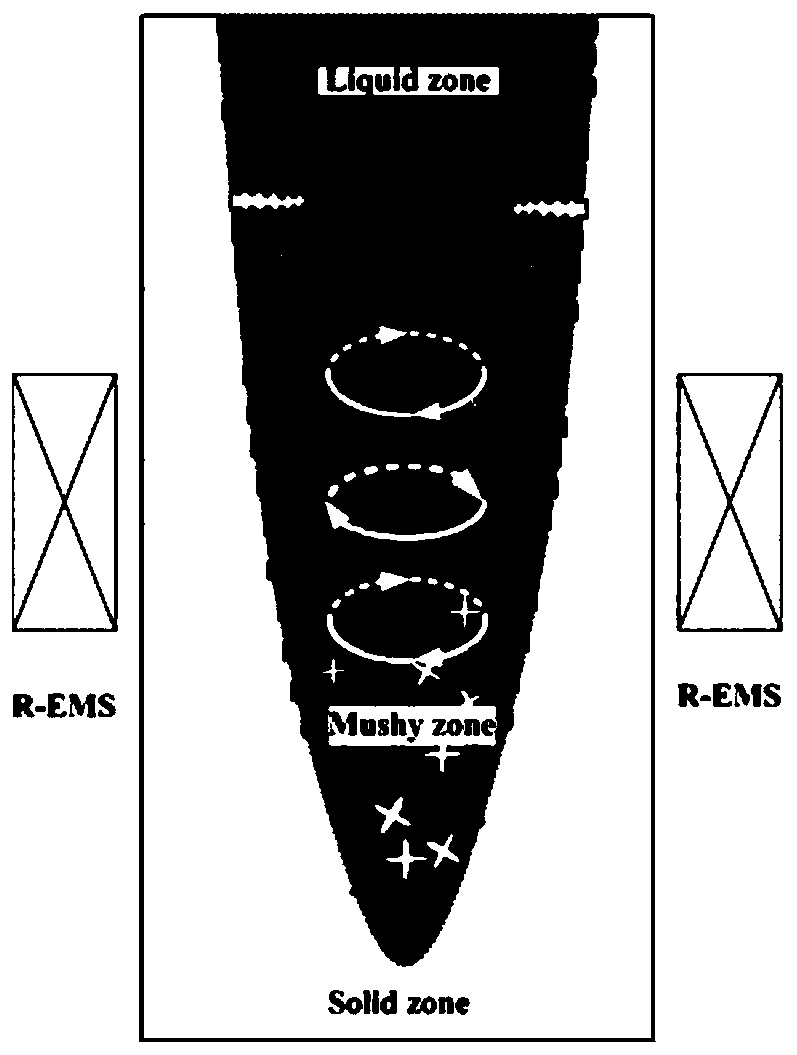

A technology of solidification end and electromagnetic stirring, which is applied in the field of metal casting, can solve the problems of insufficient mixing of molten steel, lower performance of steel products, and dead zone in the center of billet, so as to improve center segregation, improve quality, and reduce center segregation Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment l

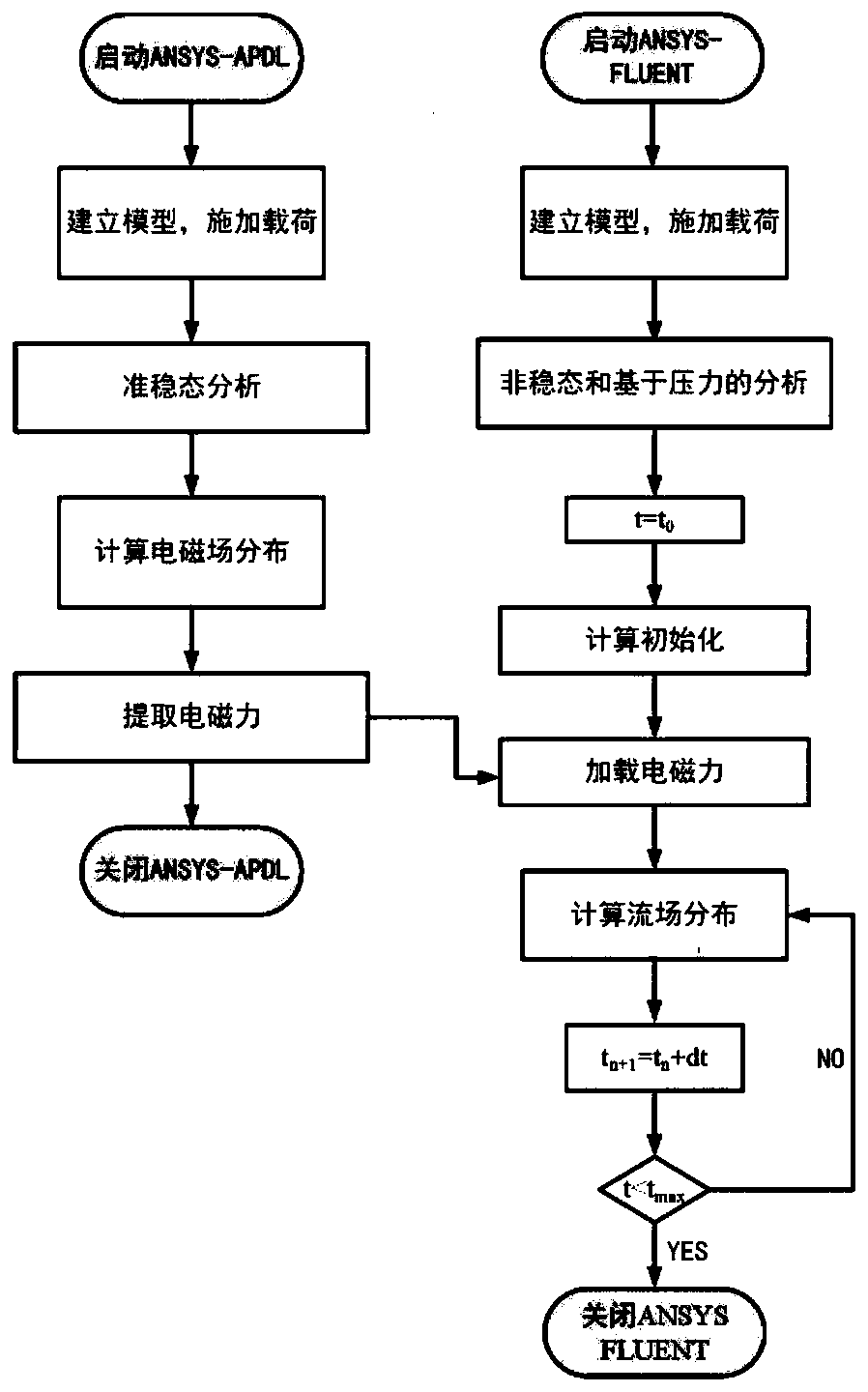

[0032] In this embodiment, a design method of traveling wave electromagnetic stirring at the end of continuous casting slab solidification, such as figure 2 shown, including the following steps:

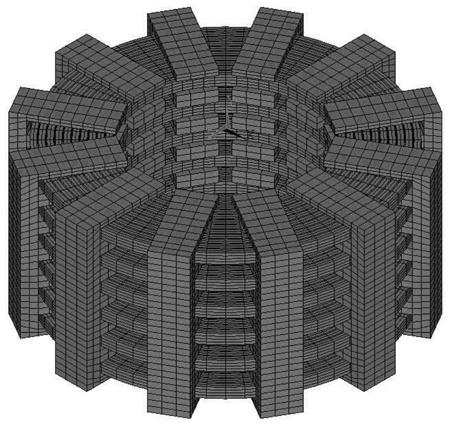

[0033] Step 1, using a traveling wave electromagnetic stirrer at the solidification end of the continuous casting slab, according to the size and parameters of the traveling wave electromagnetic stirrer, use the finite element analysis software ANSYS-APDL to establish a three-dimensional mathematical model of the traveling wave electromagnetic stirrer, as image 3 shown; wherein, the traveling wave electromagnetic stirrer parameters include current intensity, current frequency and coil turns; the mathematical model of the traveling wave electromagnetic stirrer includes iron core model, coil model, slab model and air model;

[0034] Step 1.1, load the finite element analysis software pre-processing module, define the magnetic field unit and set the coil turns, coil size, current inte...

Embodiment 2

[0050] In this embodiment, on the basis of the parameters of the casting machine and continuous casting in a steel plant, the streamline distribution of the longitudinal section of the molten steel of the billet is analyzed when a traveling wave electromagnetic stirrer is used at the end of solidification.

[0051] In this embodiment, the section diameter of the billet is 500 mm, and the casting speed of the continuous casting machine is 0.32 m / min. Table 1 below shows the physical parameters of the actually produced steel type 42CrMo steel.

[0052] Table 1 physical parameters of steel type 42CrMo steel

[0053]

[0054]

[0055] Step S1. First, determine the size of the initial traveling wave electromagnetic stirrer according to the process size of the continuous casting equipment in the steel plant, and use Gambit modeling software to establish a three-dimensional mathematical model of the traveling wave electromagnetic stirrer. The specific dimensions are shown in Tab...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com