A black phosphorus@titanium dioxide loaded noble metal composite material and its preparation method

A composite material, titanium dioxide technology, applied in the field of black phosphorus@titanium dioxide loaded noble metal composite materials and its preparation, can solve the problems of high cost of noble metals, easy corrosion of carbon carriers, limited reserves, etc., achieve high carrier mobility, easy to solve Oxidation, the effect of good electrocatalytic performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

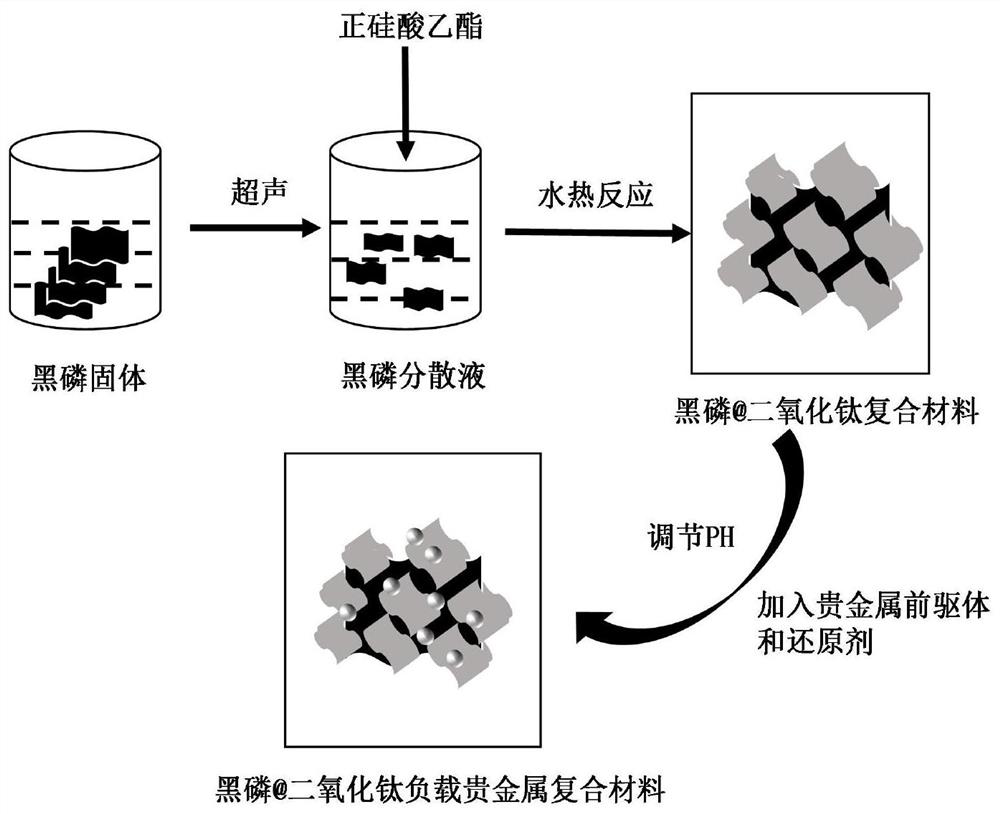

[0034] A black phosphorus@titanium dioxide loaded noble metal composite material and a preparation method thereof, comprising the following steps:

[0035] (1) Control the temperature at about 5°C, add solid black phosphorus into the N-methyl-2-pyrrolidone organic solvent, and ultrasonically disperse it with an ultrasonic pulverizer (1200W) for 2 hours, then centrifuge at 2000rpm for 20min to obtain the black phosphorus concentration of 2mg·mL -1Black phosphorus dispersion;

[0036] (2) Add 1.44mL tetrabutyl titanate and 20mg sodium dodecylsulfonate to 100mL black phosphorus dispersion in step (1), and stir until tetrabutyl titanate is completely dissolved in black phosphorus dispersion , to obtain a mixed dispersion;

[0037] (3) Transfer the mixed dispersion in step (2) into a polytetrafluoroethylene reactor, and react at 140°C for 12 hours to obtain an aqueous solution of black phosphorus@titanium dioxide composite material;

[0038] (4) Take 10mL of the aqueous solution...

Embodiment 2

[0041] A black phosphorus@titanium dioxide loaded noble metal composite material and a preparation method thereof, comprising the following steps:

[0042] (1) Control the temperature at about 10°C, add a certain mass of solid black phosphorus into the N-methyl-2-pyrrolidone organic solvent, and use an ultrasonic pulverizer (1000W) to ultrasonically disperse for 3 hours. By centrifuging at 1000rpm for 20min, the concentration of black phosphorus was 4mg·mL -1 Black phosphorus dispersion.

[0043] (2) Add 2.44mL tetrabutyl titanate and 10mg sodium dodecyl sulfonate to 100mL black phosphorus dispersion in step (1), and stir until tetrabutyl titanate is completely dissolved in black phosphorus dispersion , to obtain a mixed dispersion;

[0044] (3) Transfer the mixed dispersion in step (2) into a polytetrafluoroethylene reactor, and react at 160°C for 16 hours to obtain an aqueous solution of black phosphorus@titanium dioxide composite material;

[0045] (4) Take 10mL of the a...

Embodiment 3

[0048] A black phosphorus@titanium dioxide loaded noble metal composite material and a preparation method thereof, comprising the following steps:

[0049] (1) Control the temperature at about 5°C, add solid black phosphorus to the N,N-dimethylformamide organic solvent, and ultrasonically disperse it with an ultrasonic pulverizer (1200W) for 2 hours, then centrifuge at 2000rpm for 20 minutes to obtain the concentration of black phosphorus 5mg·mL -1 Black phosphorus dispersion;

[0050] (2) Add 1.44mL tetrabutyl titanate and 20mg cetyltrimethylammonium bromide to 50mL black phosphorus dispersion in step (1), stir until tetrabutyl titanate is completely dissolved in black phosphorus In the dispersion liquid, a mixed dispersion liquid is obtained;

[0051] (3) Transfer the mixed dispersion in step (2) into a polytetrafluoroethylene reactor, and react at 200°C for 12 hours to obtain an aqueous solution of black phosphorus@titanium dioxide composite material;

[0052] (4) Take 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com