Application of Ti3C2Tx MXenes non-noble metal heterogeneous catalyst in formic acid dehydrogenation

A non-precious metal and catalyst technology, which is applied in the field of formic acid dehydrogenation, can solve the problems of high cost, achieve stable properties, high catalyst activity, and efficiently catalyze the dehydrogenation of formic acid

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] (1) Take 1.225g of purchased commercial Ti 3 AlC 2 powder, add 15mL of 40% hydrofluoric acid, stir at room temperature for 72 hours, and selectively etch and remove the Al atomic layer in the material; pour the etched material into a centrifuge tube, add deionized water and ethanol to repeatedly centrifuge and wash, The rotating speed of the centrifuge is 7000rpm, and the centrifugation time is 10min each time until the pH value of the supernatant reaches about 6. Pour off the supernatant, and vacuum-dry the bottom material at 60°C for 24 h; finally, disperse the obtained powder in 50 ml of water, and sonicate for 24 h to obtain Ti 3 C 2 T x MXenes material;

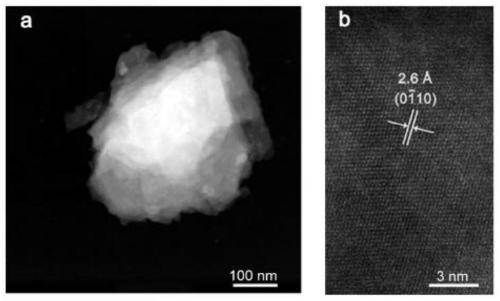

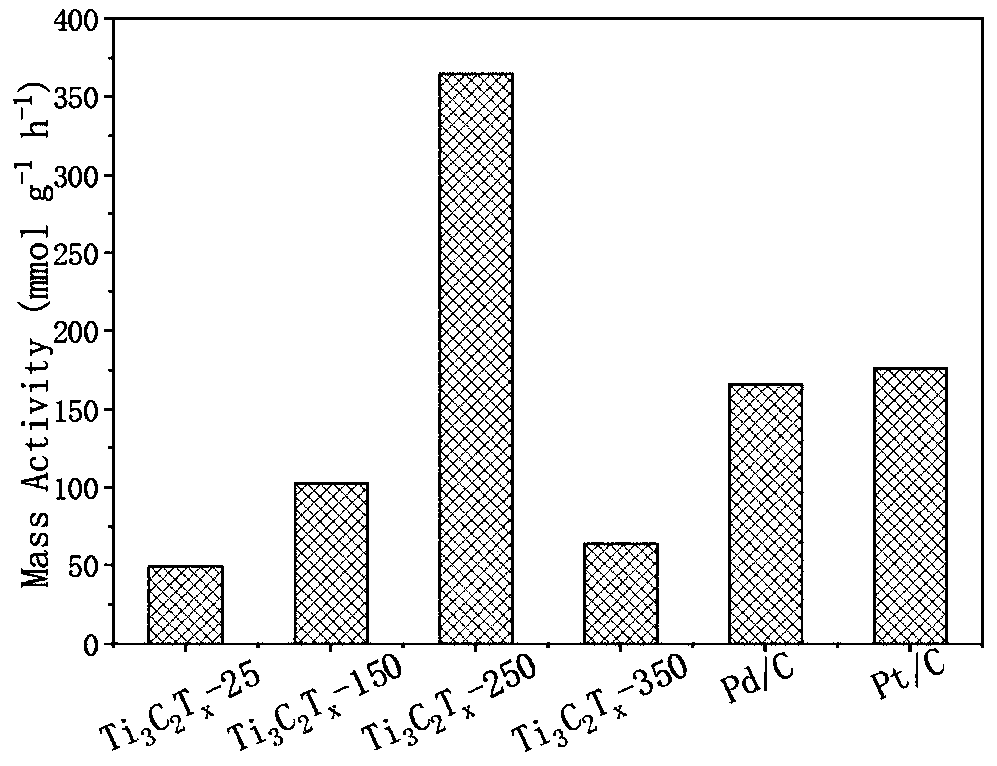

[0025] (2) Put Ti 3 C 2 T x The MXenes material was oxidized and calcined at 250 °C for 1 h in a muffle furnace to obtain Ti 3 C 2 T x -250. Such as figure 1 As shown, Ti 3 C 2 T x -250 has a layered structure, which can provide a large number of surface adsorption sites for dehydrogenation reaction...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com