Multi-walled carbon nanotube modified active powder concrete with strength grade of C100 or above and preparation method of multi-walled carbon nanotube modified active powder concrete

A technology of multi-walled carbon nanotubes and active powder, which is applied in the field of concrete to achieve obvious effects, improve the flexural strength and fatigue resistance, and improve the strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

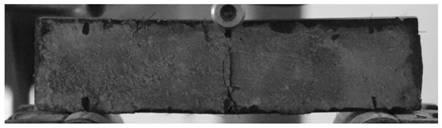

Image

Examples

specific Embodiment approach 1

[0028] A multi-walled carbon nanotube modified active powder concrete with a strength grade above C100, which is made of concrete cementitious material, steel fiber, aggregate, water, water reducing agent and carbon nanotube, carbon nanotube and concrete cementitious material The mass ratio is 0.05% to 0.15%. The weight fraction of the concrete matrix (concrete excluding carbon nanotubes) consists of: 31-33 parts of quartz sand, 22-24 parts of cement, 13-15 parts of quartz powder, 6-8 parts of water, 5-7 parts of silica fume, 4-6 parts of fly ash, 3-4 parts of steel fiber, 0.8-1.2 parts of superplasticizer.

[0029] The above-mentioned multi-walled carbon nanotubes modified active powder concrete with a strength grade above C100, the mass fraction of the multi-walled carbon nanotubes is 0.05% to 0.15% of the cementitious material, when the amount of multi-walled carbon nanotubes exceeds the above-mentioned At the upper limit of the range, MWCNTs will be unevenly dispersed and...

Embodiment 1

[0039] Compressive strength: In this embodiment, a total of 4 groups of test pieces were produced, of which 1 group without adding carbon nanotubes was used as the control group, and 3 groups of carbon nanotube-modified RPC were used as the test group.

[0040] The matrix concrete mix ratio is the same as in Example 1.

[0041] The compressive strength test uses a cube with a side length of 100mm×100mm×100mm, and three specimens are made for each group. The test groups and test results are as follows:

[0042]

[0043] As can be seen from the test data in the table, the present invention can give full play to the beneficial effect of carbon nanotubes through appropriate raw materials and carbon nanotube proportions, thereby greatly improving the compressive strength of concrete, which is 10.95% higher than that of the control group RPC , 16.25%.

Embodiment 2

[0045] Axial compressive strength test: In this embodiment, 4 groups of test pieces were produced, of which 1 group was not added with multi-walled carbon nanotubes as a control group, and 3 groups were mixed with multi-walled carbon nanotubes RPC as a test group. The weight fraction of matrix concrete is composed of: per 100 parts of concrete matrix, 31-33 parts of quartz sand, 22-24 parts of cement, 13-15 parts of quartz powder, 6-8 parts of water, 5-7 parts of silica fume, and fly ash 4-6 parts, 3-4 parts of steel fiber, 0.8-1.2 parts of superplasticizer.

[0046]The axial compressive strength test adopts a cuboid of 100mm×100mm×300mm, and three specimens are made for each group. The test groups and test results are as follows:

[0047]

[0048]

[0049] As can be seen from the test data in the table, the present invention can give full play to the beneficial effect of nanomaterials through appropriate raw materials and carbon nanotube proportions, thereby greatly imp...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size (mesh) | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com