High-activity multilayer composite microsphere and preparation method thereof

A multi-layer composite and high-activity technology, applied in the direction of offensive equipment, explosive processing equipment, explosives, etc., can solve problems such as low energy utilization efficiency, hidden safety hazards, complex processes, etc., to meet the needs of development and application, and shorten mass transmission Effect of distance, high energy release rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

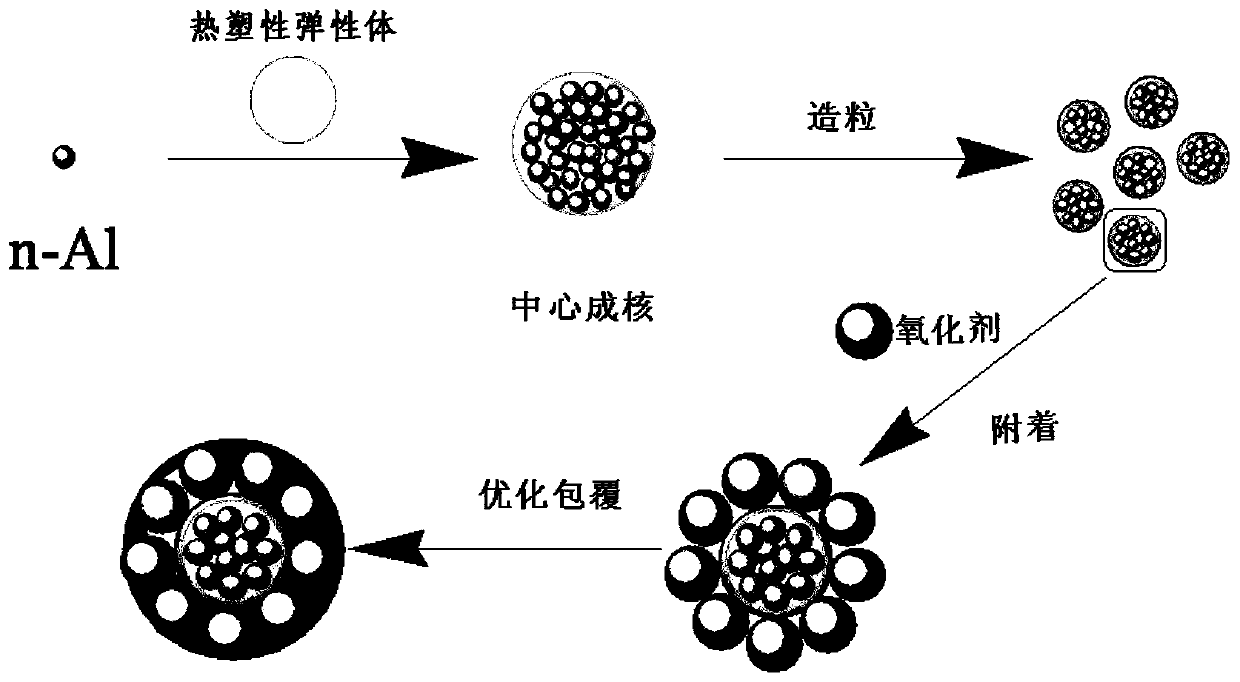

[0034] The preparation method of this highly active multilayer composite microsphere is as follows:

[0035] In step (1), use a rotary evaporator to distill the process additives under reduced pressure to remove water and purify the process additives; the vacuum distillation conditions are vacuum degree -0.1MPa~0MPa, temperature 70°C~90°C, time 60min~120min, Speed 20rpm ~ 100rpm.

[0036] In step (2), in order to mix the metal powder and the process additive evenly, manually stir and mix the nano metal powder and the process aid in a glove box for 15-30 minutes to form slurry A.

[0037] Step (3), melt and mix the plastic elastomer and slurry A under certain temperature conditions, and stir to prepare a uniform slurry B. In order to melt the thermoplastic elastomer and facilitate mixing, control the temperature at 80°C to 85°C; control the electric stirring time If the stirring time is too short, the metal powder cannot be fully dispersed to form a uniform slurry. If the st...

Embodiment 1

[0041] In this example, a high-activity multilayer composite microsphere was prepared, and the preparation method was as follows:

[0042] Step (1), weigh a certain amount of dioctyl sebacate, and distill under reduced pressure for 120min under the conditions of vacuum degree of -0.1MPa, temperature of 70°C, and rotation speed of 20rpm;

[0043]In step (2), 25g of nano-aluminum powder and 5g of dioctyl sebacate were manually stirred and mixed for 30min in a glove box to form slurry A;

[0044] In step (3), 15 g of EVA was melted and mixed with slurry A at a temperature of 85° C., and electric stirring was performed for 30 minutes to obtain uniform slurry B, and the electric stirring speed was 50 rpm;

[0045] In step (4), the prepared slurry B is pressurized by a high-pressure peristaltic pump and then enters a pressure nozzle, the feed rate is 0.5g / min, the nozzle temperature is 95°C, and the internal and external pressure difference is 1MPa. The sprayed molten droplets dire...

Embodiment 2

[0050] In this example, a high-activity multilayer composite microsphere was prepared, and the preparation method was as follows:

[0051] Step (1), weigh a certain amount of naphthenic oil and stearic acid, and distill under reduced pressure for 90min under the conditions that the vacuum degree is -0.1MPa, the temperature is 70°C, and the rotation speed is 80rpm;

[0052] In step (2), 22g of nano-aluminum-magnesium alloy powder, 4g of naphthenic oil and 4g of stearic acid were manually stirred and mixed for 20 minutes in a glove box to form slurry A;

[0053] In step (3), 12 g of thermoplastic polyurethane is melted and mixed with slurry A at a temperature of 84° C., and electric stirring is performed for 30 minutes to obtain uniform slurry B, and the rotating speed of electric stirring is 45 rpm;

[0054] In step (4), the prepared slurry B is pressurized by a high-pressure peristaltic pump and then enters a pressure nozzle with a feed rate of 10 g / min, a nozzle temperature o...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com