A solid waste pyrolysis liquid phase product molten salt cascade treatment impurity removal and upgrading device

A technology of pyrolysis liquid and molten salt, which is applied in tar processing, tar processing, petroleum industry and other directions by heat treatment method, which can solve the problems of secondary pollution, low utilization rate of energy conversion, and inefficient treatment of solid waste pyrolysis liquid phase products. and other problems, to avoid the mixing of components and achieve the effect of high recycling efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

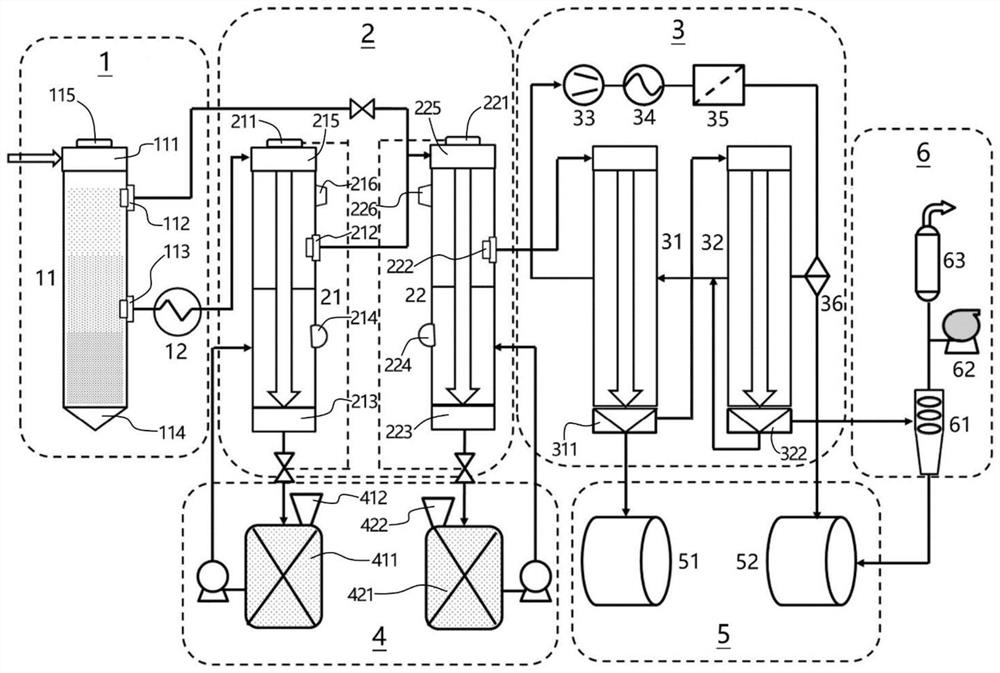

[0038] The first liquid outlet 112 of the tar classification unit 1 is connected to the feed port of the secondary molten salt reactor 22, the check valve is arranged in the connected pipeline, and the second liquid outlet 113 is connected to the primary molten salt reactor 21. The feed port and the heater 12 are arranged in the connected pipeline.

[0039] The outlets of the first molten salt separator 213 and the second molten salt separator 223 are connected to the molten salt regeneration unit 4, and the outlet of the first molten salt storage bin 411 is connected to the molten salt return port of the primary molten salt reactor 21 through a pump , the outlet of the second molten salt storage bin 421 is connected to the molten salt return port of the secondary molten salt reactor 22 through a pump, and the molten salt regenerated in the molten salt regeneration unit 4 is respectively reintroduced into the primary molten salt through the molten salt return port Reactor 21 a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com