Method for removing and utilizing absorption circulating acid heat in sulfuric acid process

A technology of absorption cycle and acid absorption, applied in heating methods, cooling fluid circulation devices, applications, etc., can solve the problems of insufficient utilization of waste heat, waste of water resources, etc., and achieve significant direct and ecological benefits, efficient recycling, and extensive use Promoting the effect of app value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

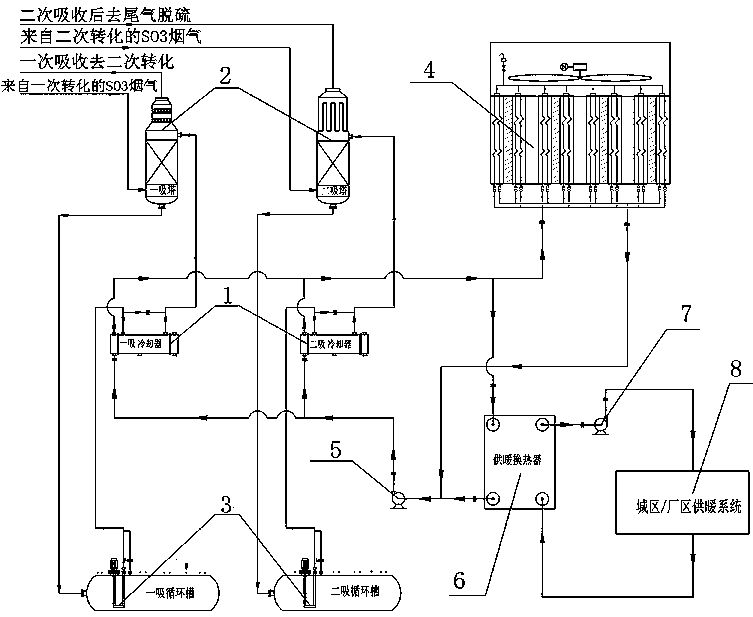

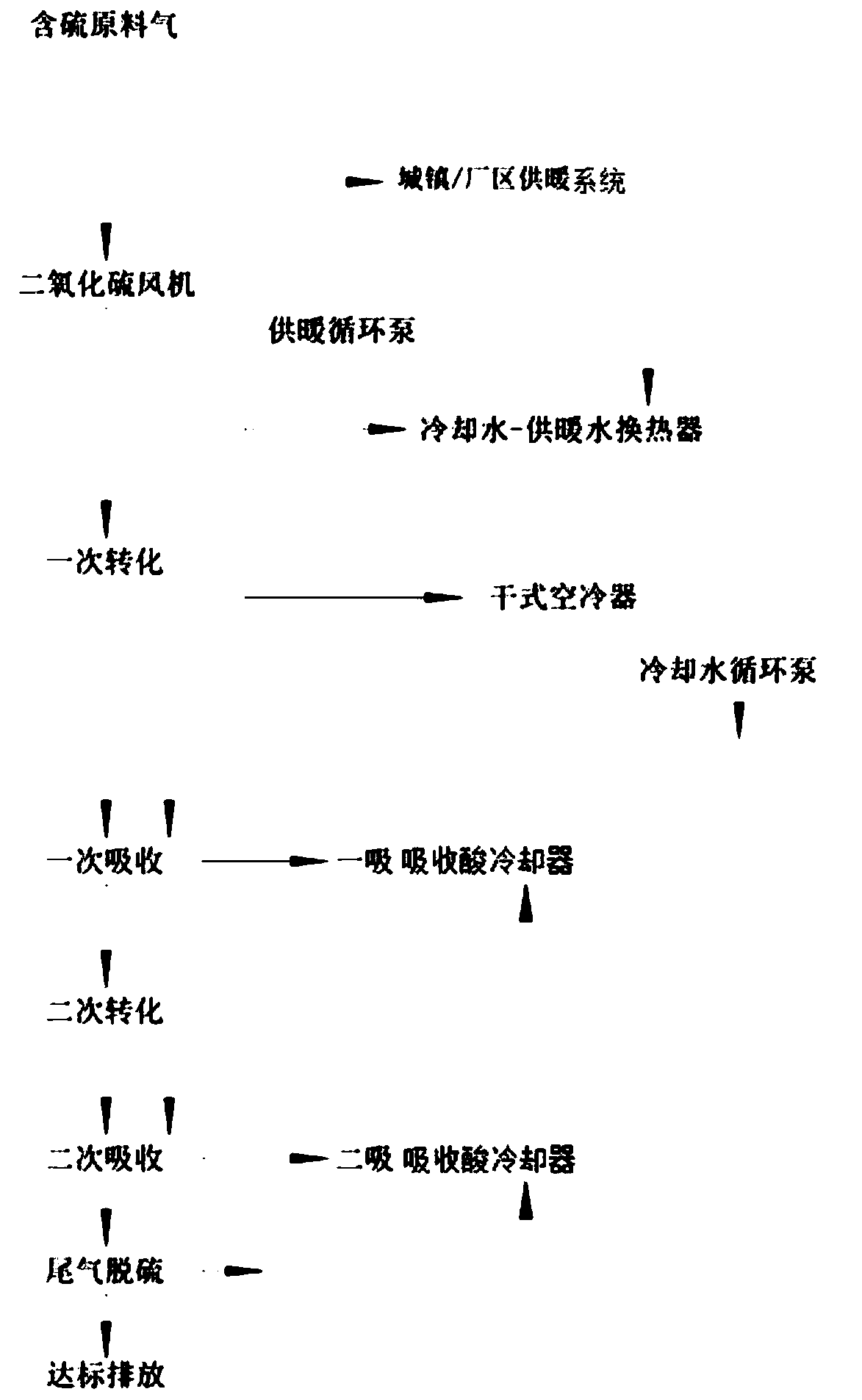

[0017] A set of this device is respectively connected to the primary absorption tower and the secondary absorption tower. Among them, absorption acid cooler 1# (primary absorption absorption acid cooler) has an acid inlet temperature of 100°C and an acid outlet temperature of 78°C, and the absorption acid cooler 2# (second suction absorption acid cooler) acid inlet temperature 90°C, acid outlet temperature 75°C, cold side inlet water temperature 55°C, outlet water temperature 65°C, closed circulation cooling water unit dry air cooler inlet water temperature 65°C, the outlet water temperature after cooling is 55°C, the cooling water-heating water heat exchanger configured in parallel with the closed cycle cooling water unit has a cold side inlet water (heating water return) temperature of 40°C, and a cold side outlet water (heating water supply water) ) temperature of 60°C. The heat removal task of absorption cycle acid is completed by absorption acid cooler and closed cooling ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com