Thermal ion conversion and Brayton cycle combined power generation reactor system

A technology of Brayton cycle and combined power generation, which is applied in the direction of using thermoelectric element generators, nuclear power generation, machines/engines, etc., can solve the problems of low thermoelectric conversion efficiency and heat loss, so as to improve inherent safety, improve utilization efficiency, Achieve the effect of miniaturization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

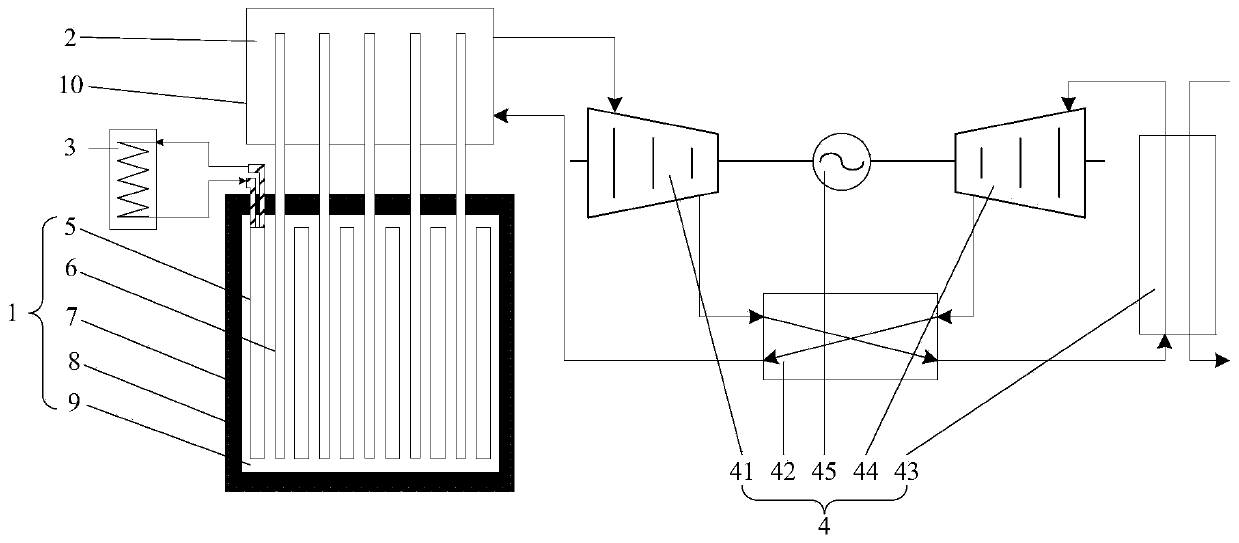

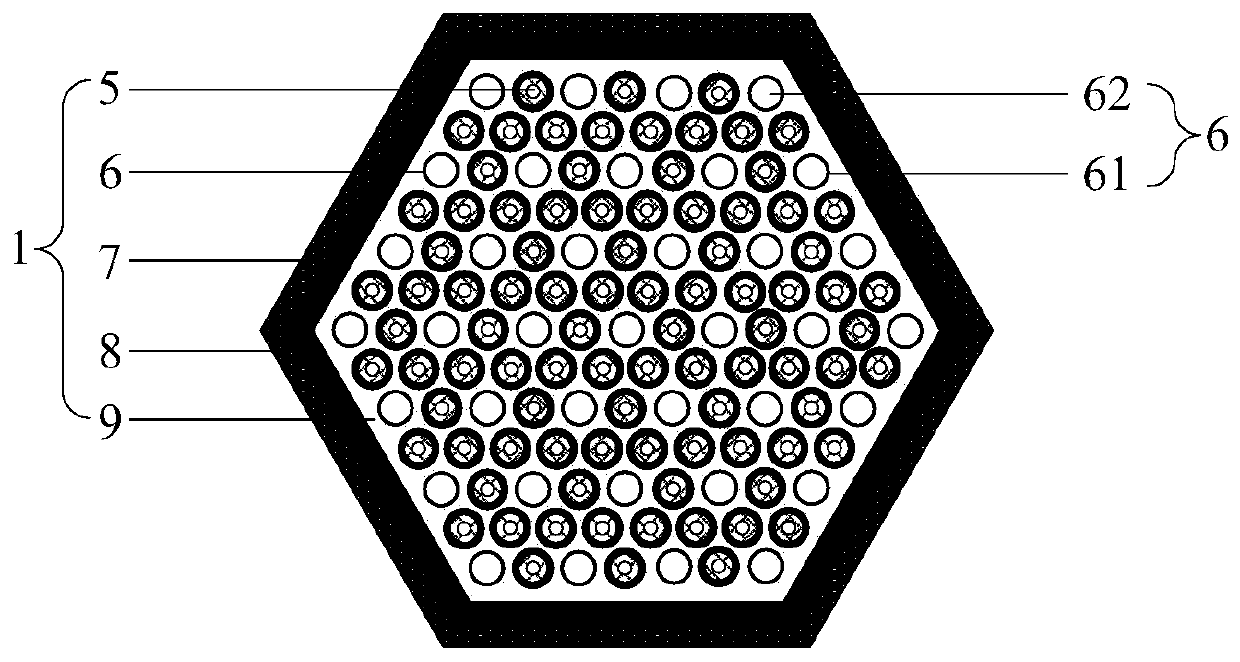

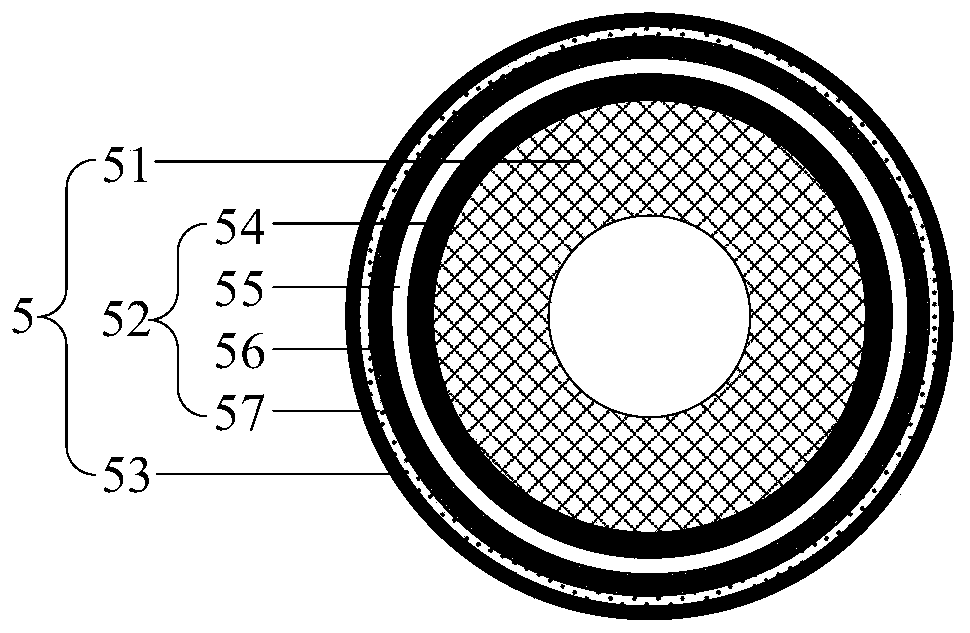

[0021] Such as figure 1 As shown, it is an embodiment of the thermionic conversion and Brayton cycle joint power generation nuclear reactor system of the present invention, which includes a thermionic conversion module 1, an intermediate heat exchanger 2 and a Brayton cycle module 4; the thermionic conversion module 1 is equipped with The thermionic thermoelectric conversion element 5 and the alkali metal heat pipe 6 are covered with a reflective layer 7 and a shielding layer 8; a through heat pipe 6 is arranged between the thermionic conversion module 1 and the intermediate heat exchanger 2; the heat pipe 6 is divided into an evaporation section And the condensation section, the heat pipe 6 is partially set as an evaporation section in the thermionic conversion module 1, and the heat pipe 6 is partially set as a condensation section ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com