A kind of preparation method of deep groove lateral withstand voltage region with longitudinal linear variable doping

A technology of lateral withstand voltage and withstand voltage region, which is applied in semiconductor/solid-state device manufacturing, semiconductor devices, electrical components, etc., and can solve problems such as difficult to achieve charge balance state and limit device performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

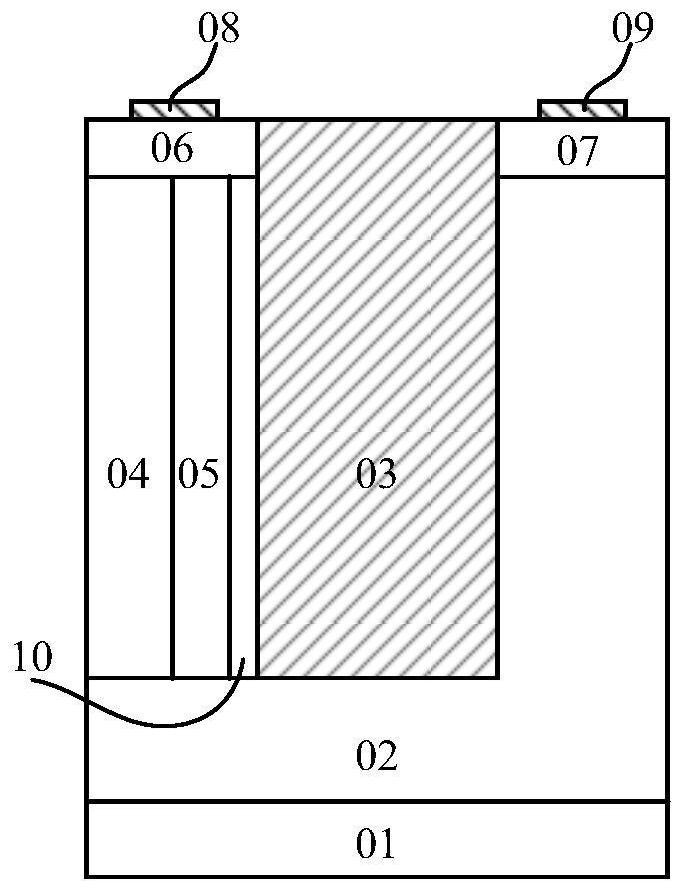

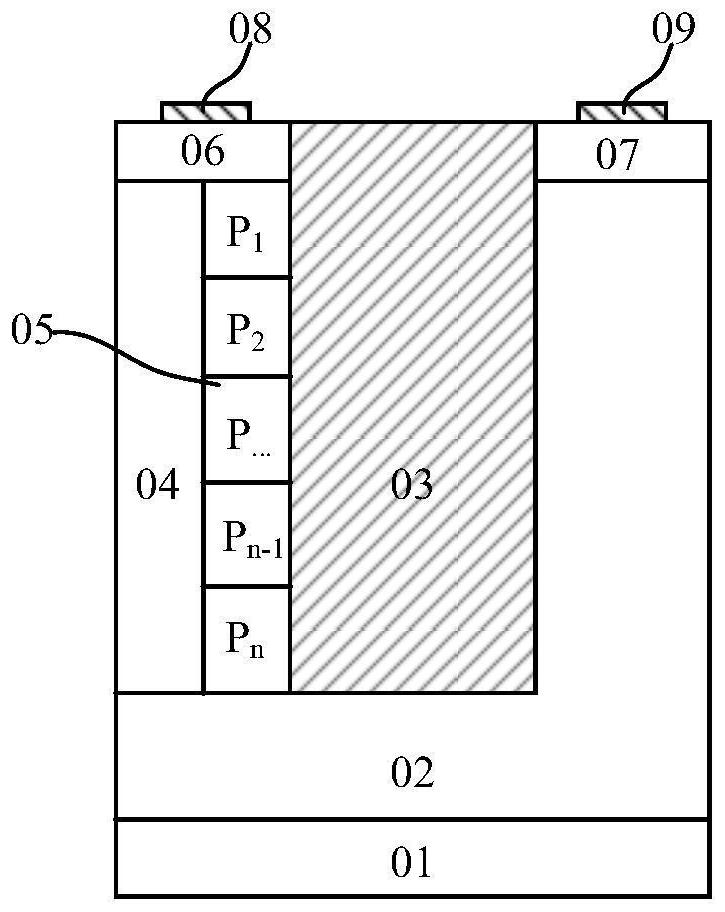

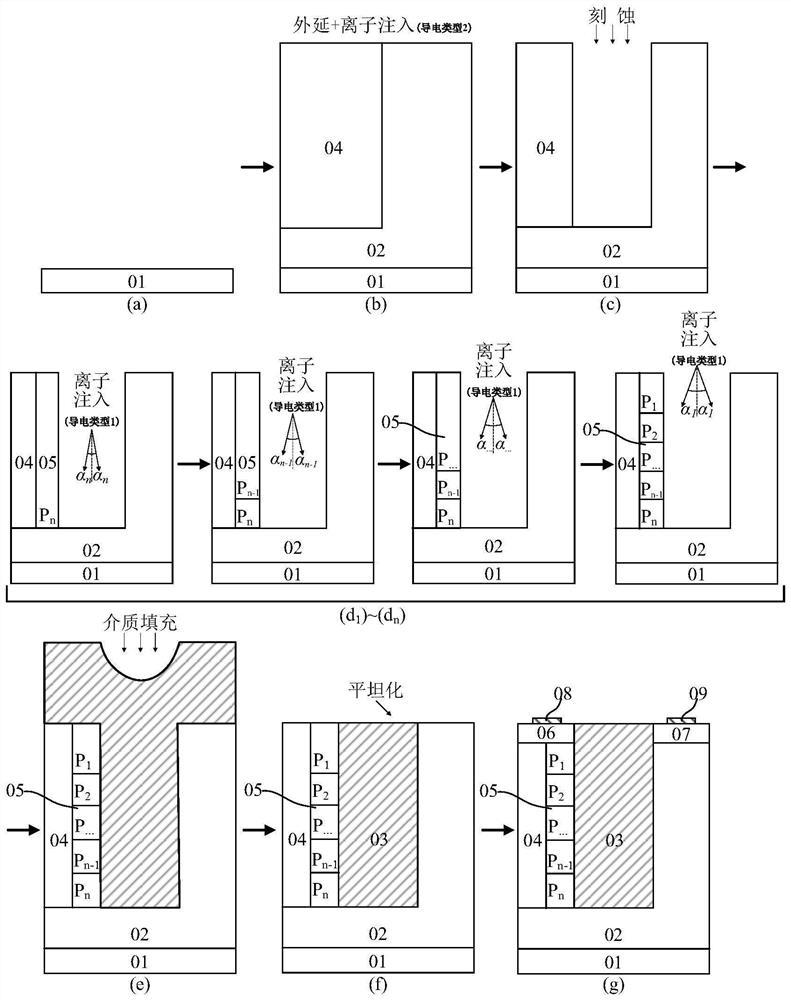

[0036] This embodiment provides a method for preparing a deep trench lateral voltage withstand region with longitudinal linearly variable doping on one side, and the structure of the deep trench lateral voltage withstand region with longitudinal linearly variable doping on one side is as follows Image 6 As shown, the specific process flow is as follows Figure 7 shown, including the following steps:

[0037] Step 1: Prepare before processing and clean the semiconductor;

[0038] Step 2: Perform epitaxy on the substrate 01 to form a withstand voltage region 04, such as Figure 7 as shown in (a);

[0039] Step 3: Etching the withstand voltage region 04 to form a first rectangular deep groove in the withstand voltage region, such as Figure 7 as shown in (b);

[0040] Step 4: Carry out epitaxy on the deep groove, and form a withstand voltage region 05 in the deep groove, such as Figure 7 as shown in (c);

[0041] Step 5: Process the chute on the pressure-resistant zone 05 t...

Embodiment 2

[0048] This embodiment provides a method for preparing a deep groove lateral voltage-sustaining region with longitudinal linear variable doping on both sides, the structure of the deep groove lateral voltage-sustaining region having longitudinal linear variable doping on both sides is as follows Figure 8 As shown, the specific process flow is as follows Figure 9 shown, including the following steps:

[0049] Step 1~step 9 are identical with embodiment 1;

[0050] Step 10: Carry out chute processing on the flat medium 03 and the pressure-resistant area 05 again to form a second chute in the shape of an "inverted trapezoid" with a narrow bottom and a wide top. The opening width of the second chute is w 3 , formed as Figure 9 (i) The chute shown in (i), the inclination angle of the chute is β, and the depth is h;

[0051] Step 11: Perform ion implantation with an inclination angle α on the side wall of the second chute processed in step 10, and form the following on the rig...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com