Fiber metal three-dimensional composite board and preparation method thereof

A fiber metal and composite board technology, applied in metal layer products, chemical instruments and methods, lamination, etc., can solve the problems of affecting the comprehensive mechanical properties of the laminate, weak bonding force between the metal layer and the fiber, weakening the overall strength of the structure, etc. , to achieve the effect of improving the level of lightweight design and impact resistance, excellent structural integrity, and good optimizability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] A method for preparing a fiber metal three-dimensional composite panel, comprising the following steps:

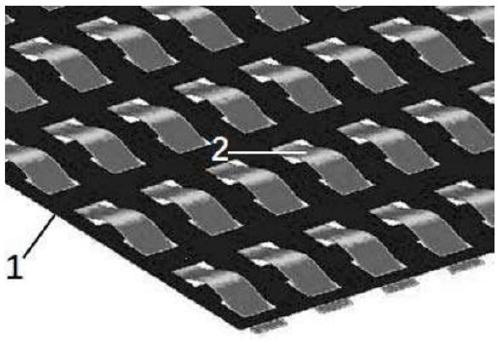

[0026] Step 1: Punch square holes on an aluminum alloy plate with a thickness of 0.5mm to form a regular array of holes. The side length of the holes is 3mm and the hole spacing is 3mm. Weave the basalt fiber roving with a width of 3mm into the perforated aluminum alloy plate in plain weave on, formed as figure 1 fiber metal single-layer panels;

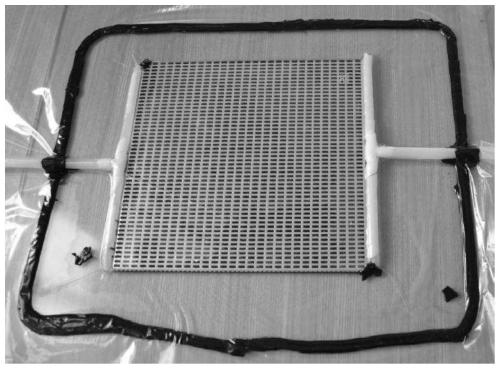

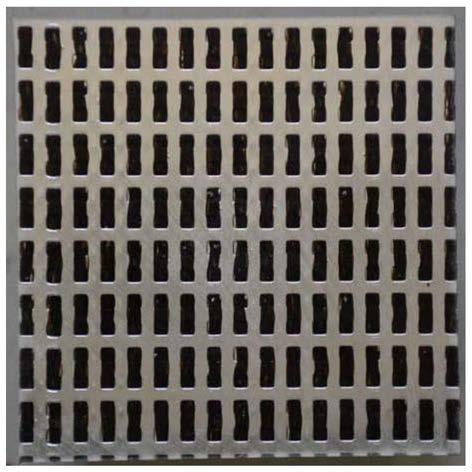

[0027] Step 2, stack two layers of fiber metal single-layer boards in the same direction, and place them on such as figure 2 Into the vacuum bag of the flat mold, introduce epoxy resin, evacuate until the air is completely extracted, close the valve, export excess epoxy resin, and then cure at 70°C for 180min to obtain a fiber-metal three-dimensional composite board, such as image 3 .

Embodiment 2

[0029] A method for preparing a fiber metal three-dimensional composite panel, comprising the following steps:

[0030] Step 1: Punch square holes on an aluminum alloy plate with a thickness of 0.5mm to form a regular array of holes. The side length of the holes is 3mm and the hole spacing is 3mm. Weave the basalt fiber roving with a width of 3mm into the perforated aluminum alloy plate in plain weave On, forming a fiber metal single-layer board;

[0031] Step 2, stack two layers of fiber metal single-layer boards and place them on such as Figure 4 Into the vacuum bag of the single-curvature mold, introduce epoxy resin, evacuate until the air is completely extracted, close the valve, export excess epoxy resin, and then cure at 70°C for 180min to obtain a single-curvature fiber-metal three-dimensional composite panel, such as Figure 5 .

[0032] Among them, the square hole on the aluminum alloy plate can be replaced by any polygonal hole.

Embodiment 3

[0034] A method for preparing a fiber metal three-dimensional composite panel, comprising the following steps:

[0035] Step 1: Punch square holes on an aluminum alloy plate with a thickness of 0.5mm to form a regular array of holes with a diameter of 3mm and a hole spacing of 3mm. Weave basalt fiber rovings with a width of 3mm into the perforated aluminum alloy plate in a twill weave , forming a fiber metal single-layer board;

[0036] Step 2, stack the two-layer fiber metal single-layer boards and place them on such as Figure 4 Introduce epoxy resin into the vacuum bag of the single-curvature mold, evacuate until the air is completely extracted, close the valve, export excess epoxy resin, and then cure at 70°C for 180min to obtain a single-curvature fiber metal three-dimensional composite panel.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com