Efficient circulating self-crystallization solid-liquid separation device

A solid-liquid separation and self-crystallization technology, which is applied in the direction of separation method, sedimentation separation, sediment separation by centrifugal force, etc., can solve the problems of low efficiency of solid-liquid separation of fine sand, pollution of the environment, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

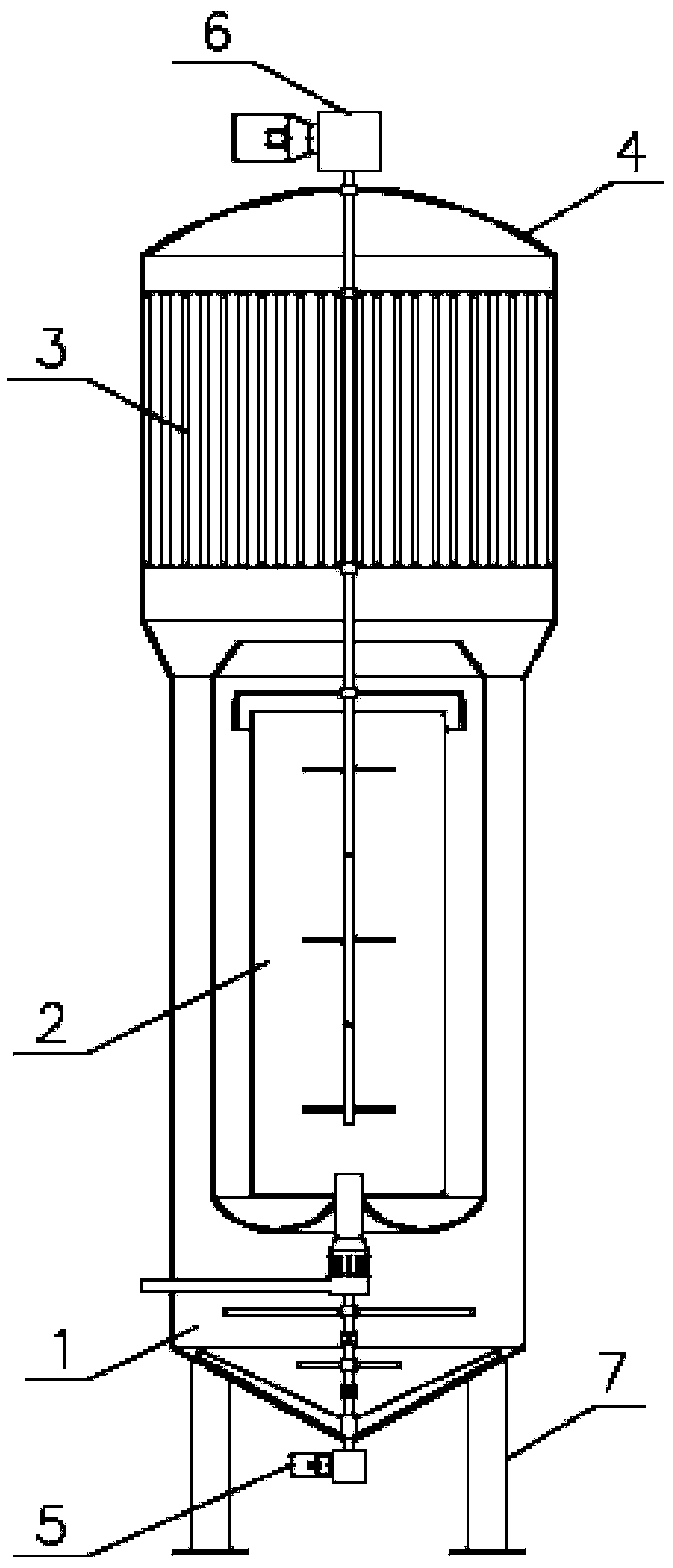

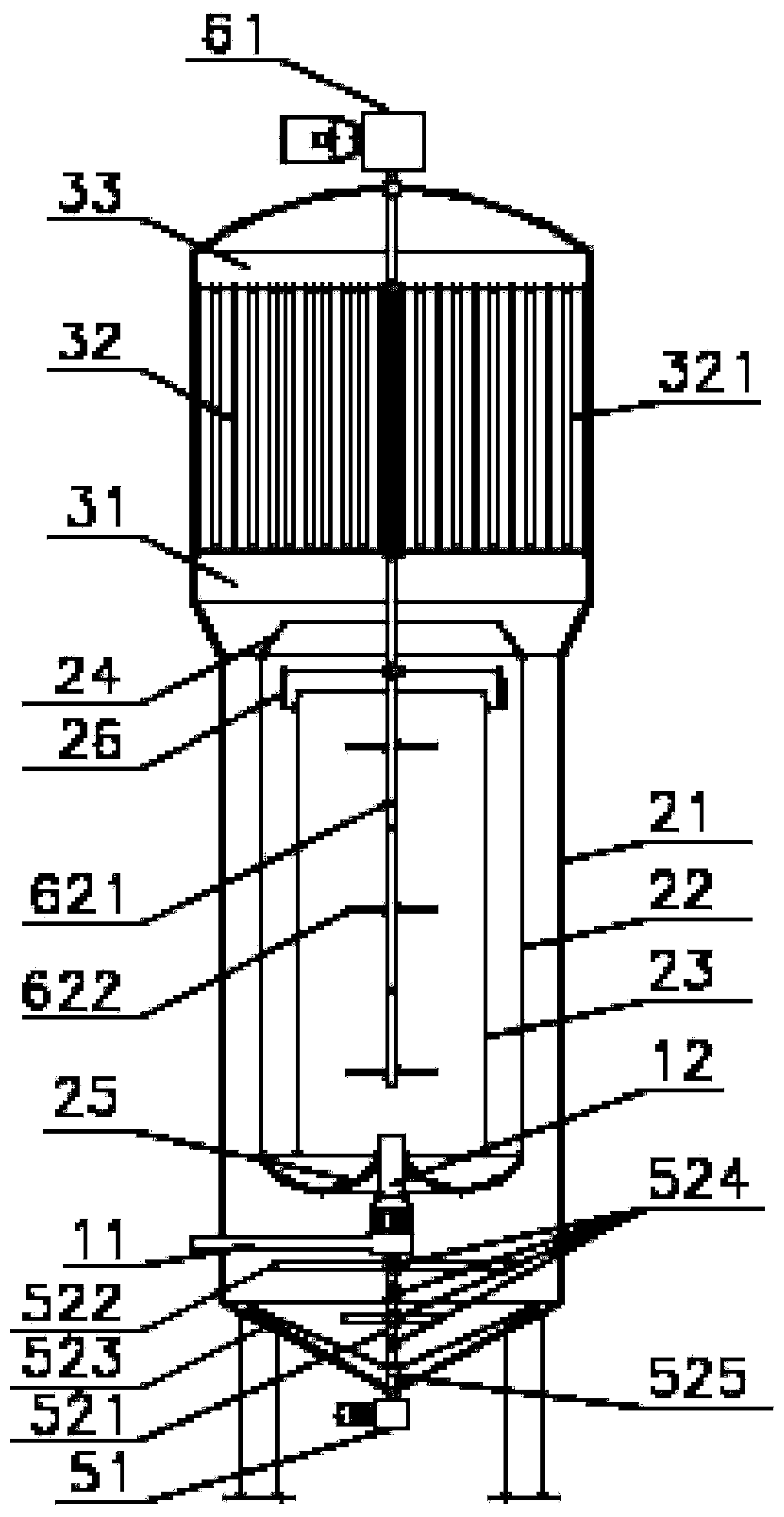

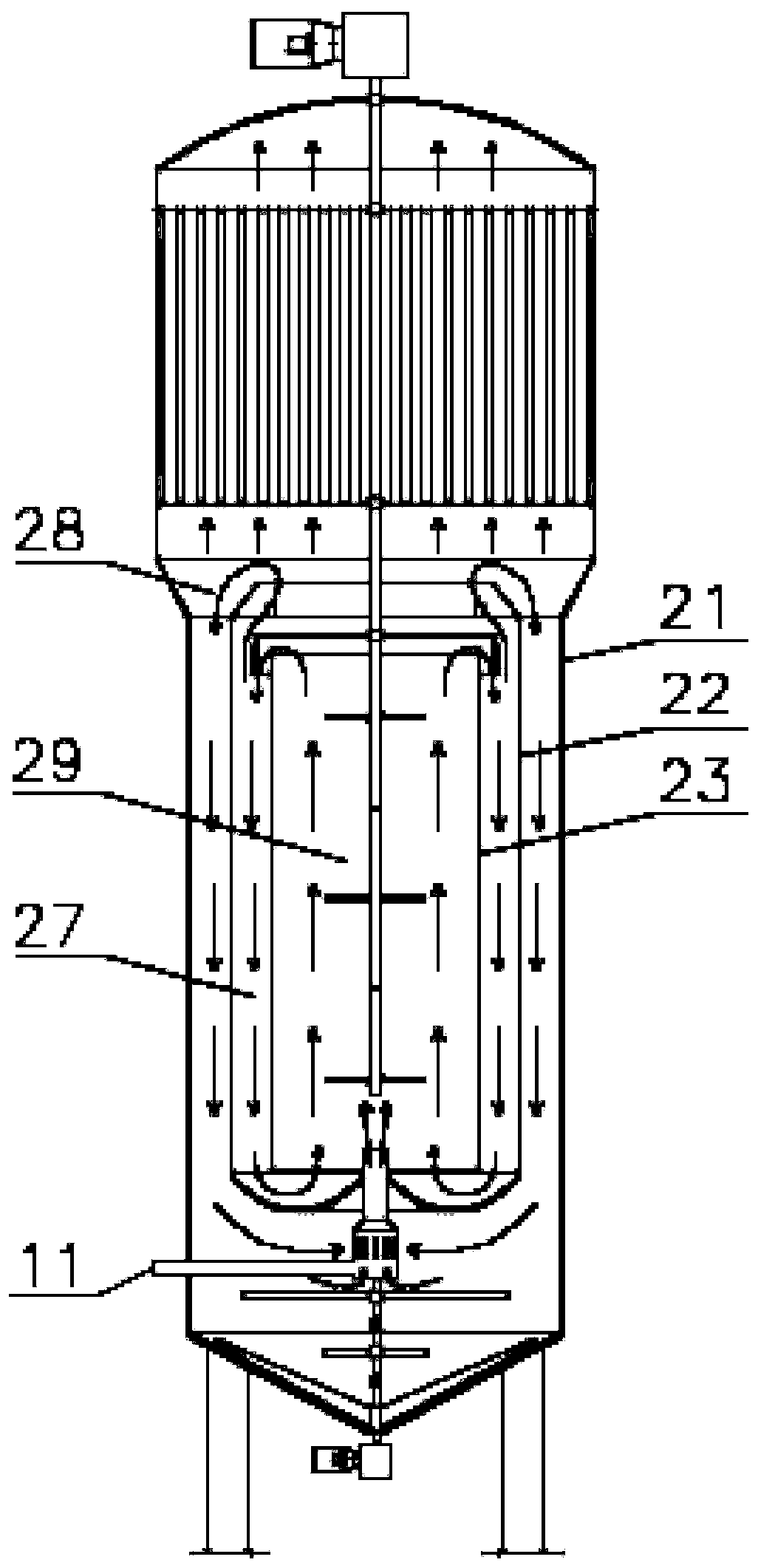

[0054] Such as Figure 1-16 As shown, a high-efficiency circulating self-crystallization solid-liquid separation device includes a sludge area 1, a circulating crystallization area 2, a solid-liquid separation area 3, and a head 4 arranged sequentially from bottom to top, and the sludge area 1 is connected. The first power facility 5, the second power facility 6 connected to the solid-liquid separation zone 3 and the legs 7 arranged outside the bottom of the sludge zone 1, the sludge zone 1, the circulating crystallization zone 2, and the solid-liquid separation zone 3 and the head 4 form a closed structure;

[0055] The sludge area 1 includes a water inlet pipe 11, a negative pressure component 12 connected to the inner end of the water inlet pipe 11, and a sludge discharge pipe 13 located on one side of the sludge area 1. The bottom of the sludge area 1 is tapered; the negative pressure component 12 includes Outer cover 121, body 122 and gradual expansion part 123; Outer co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com