A kind of polyurethane modified acrylate uv resin and preparation method thereof

A polyurethane modification and acrylate technology, applied in polyurea/polyurethane coatings, coatings, etc., can solve problems such as poor adhesion and toughness, achieve smooth surfaces, expand applications, improve wear resistance and flexibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0044] The second aspect of the present invention provides a kind of preparation method of described polyurethane modified acrylate UV resin, comprises the steps:

[0045] (1) Add diisocyanate into the reaction flask, heat up to 50-70°C, add dihydric alcohol dropwise, react, and cool down to obtain product A;

[0046] (2) Under the condition of avoiding light, add the acrylate monomer into the reaction bottle, raise the temperature, then slowly add ethanolamine dropwise, react, and cool down to obtain the product B;

[0047] (3) Under the protection of argon, under the condition of avoiding light, add the product B into the reaction bottle, raise the temperature to 50-70° C., add the product A dropwise, react, and cool down to obtain the polyurethane modified acrylate UV resin.

[0048] Preferably, the preparation method of described polyurethane modified acrylate UV resin, comprises the steps:

[0049] (1) Add diisocyanate into the reaction flask, raise the temperature to 50...

Embodiment 1

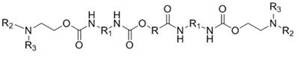

[0066] Embodiment 1 provides a kind of polyurethane modified acrylate UV resin, and its structural formula is as follows:

[0067]

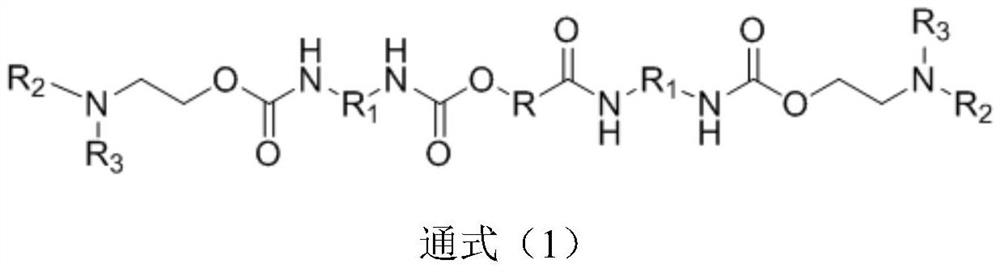

[0068] R is no 2 about 17; R 1 for R 2 , R 3 both Among them, R 4 is hydrogen; R 5 for m 2 is 3;

[0069] The preparation method of described polyurethane modified acrylate UV resin is as follows:

[0070] (1) Under the protection of argon, add 348.3g of diisocyanate into the reaction flask, raise the temperature to 60-65°C, stir, add 1000g of dihydric alcohol dropwise, continue the reaction for 4.5h after the dropwise addition, stop the reaction, and cool down to obtain the product A1, 1348.3g;

[0071] (2) Under the condition of avoiding light, add 600.7g of acrylate monomer into the reaction bottle, raise the temperature to 50°C, stir, then slowly add 61g of ethanolamine dropwise, after the dropwise addition, continue to keep warm for 2 days, and there is no raw material peak in chromatographic detection Afterwards, the rea...

Embodiment 2

[0075] Embodiment 2 provides a kind of polyurethane modified acrylate UV resin, and its structural formula is as follows:

[0076]

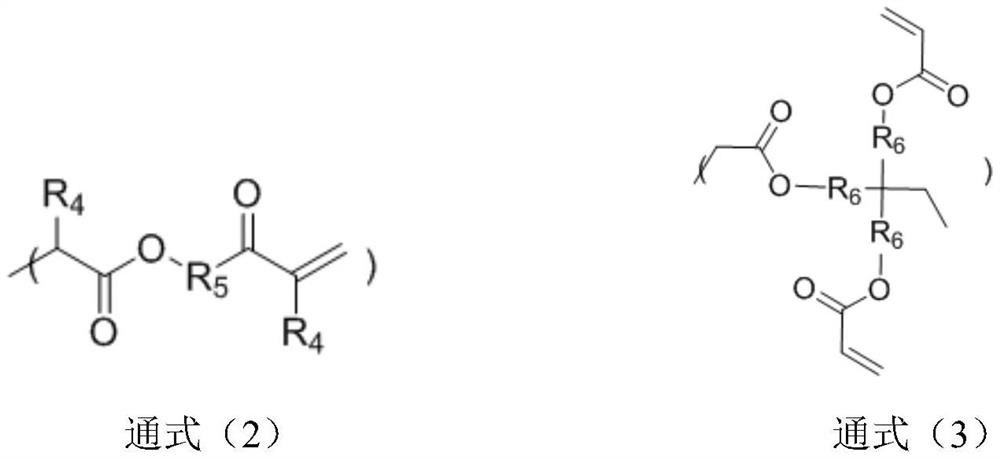

[0077] R is no 2 about 17; R 1 for R 2 , R 3 both Among them, R 6 for

[0078] The preparation method of described polyurethane modified acrylate UV resin is as follows:

[0079] (1) Under the protection of argon, add 348.3g of diisocyanate into the reaction flask, raise the temperature to 60-65°C, stir, add 1000g of dihydric alcohol dropwise, continue the reaction for 4.5h after the dropwise addition, stop the reaction, and cool down to obtain the product A2, 1348.3g;

[0080] (2) Under the condition of avoiding light, add 592.6g of acrylate monomer into the reaction bottle, raise the temperature to 50°C, stir, then slowly add 61g of ethanolamine dropwise, after the dropwise addition, continue to keep warm for 2 days, and there is no raw material peak in chromatographic detection Afterwards, the reaction was stopped, and the te...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com