Preparation method of visible light activated nano self-cleaning coating for engineering

A visible light and nano technology, used in coatings, biocide-containing paints, antifouling/underwater coatings, etc., can solve the problems of inability to achieve self-cleaning, weakened self-cleaning effect, poor visible light effect, etc., to promote compatibility. performance, long-lasting self-cleaning performance, and better film-forming properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

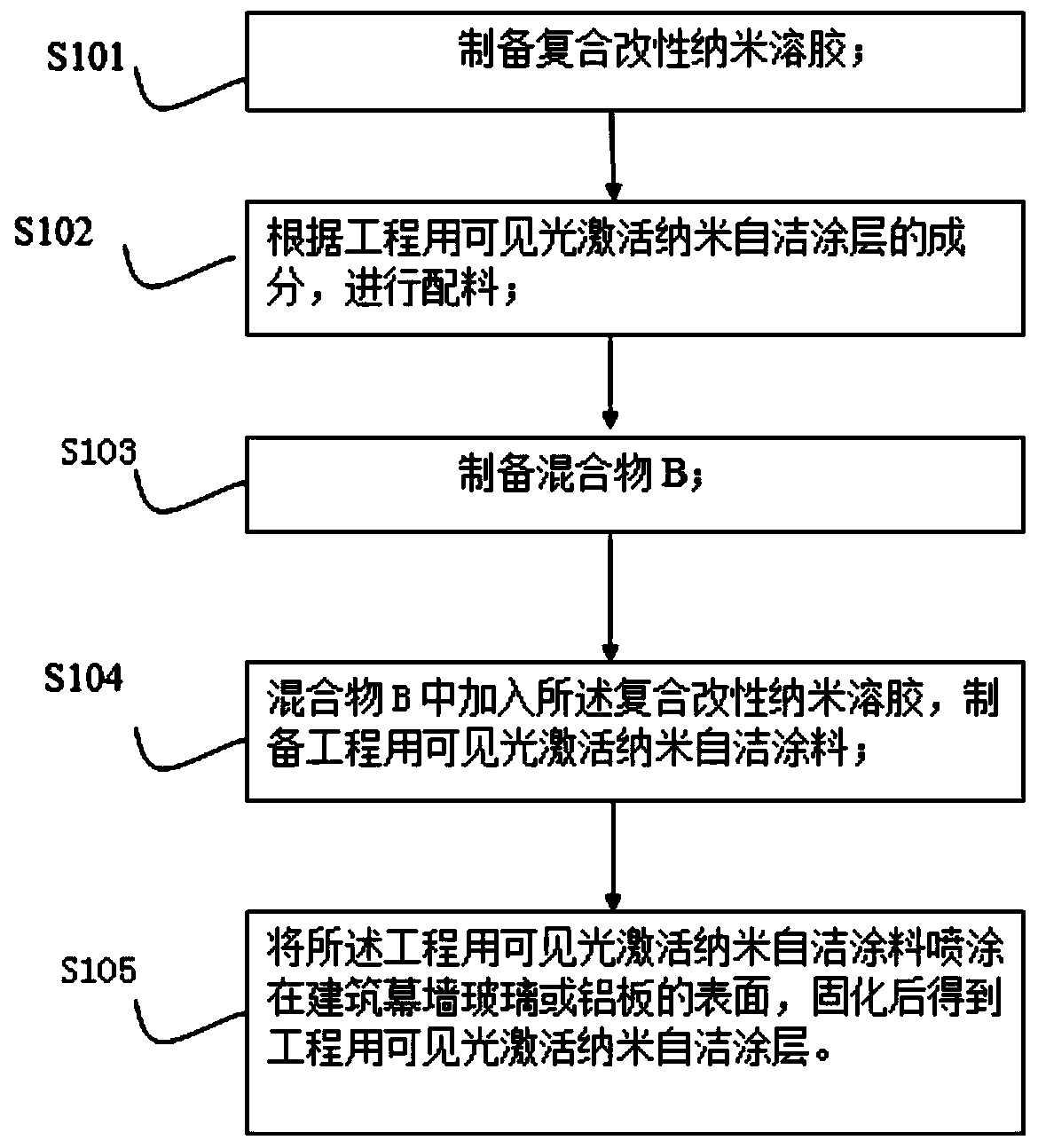

Method used

Image

Examples

Embodiment 1

[0029] This embodiment provides a preparation method of visible light-activated nano self-cleaning coating for engineering. The preparation method includes the preparation of composite modified nano sol, and the composite modified nano sol includes nano carbon dioxide and nano Silica is prepared according to the ratio of 1:2 in mass percentage, and the active group is acrylate, and the preparation of the composite modified nano-sol is: the above-mentioned mass percentage of nano carbon dioxide and nano Silica is mixed, and water is added with a volume of 3 times. Under the action of ultrasonic vibration, the conditions of ultrasonic vibration here are: the ultrasonic frequency is 20kHz, and the ultrasonic power is 200W to form a uniform mixture A; the mixture A is added dropwise into the mixture of tetraethyl orthosilicate, alcohol and coupling agent, and fully stirred evenly to obtain composite modified nano-sol.

[0030] Wherein, in this embodiment, the visible light-activat...

Embodiment 2

[0037]This embodiment provides a preparation method of visible light-activated nano self-cleaning coating for engineering. The preparation method includes the preparation of composite modified nano sol, and the composite modified nano sol includes nano carbon dioxide and nano Silica is prepared according to the ratio of 3:2 by mass percentage, and the active group is acrylate, and the preparation of the composite modified nano-sol is: the above-mentioned mass percentage of nano carbon dioxide and nano Silica is mixed, and water is added with a volume of 5 times. Under the action of ultrasonic vibration, the conditions of ultrasonic vibration here are: the ultrasonic frequency is 45kHz, and the ultrasonic power is 250W to form a uniform mixture A; the mixture A is added dropwise into the mixture of tetraethyl orthosilicate, alcohol and coupling agent, and fully stirred evenly to obtain composite modified nano-sol.

[0038] Wherein, in this embodiment, the visible light-activate...

Embodiment 3

[0045] This embodiment provides a preparation method of visible light-activated nano self-cleaning coating for engineering. The preparation method includes the preparation of composite modified nano sol, and the composite modified nano sol includes nano carbon dioxide and nano Silica is prepared according to the ratio of 2:5 in mass percentage, and the active group is acrylate, and the preparation of the composite modified nano-sol is: the above-mentioned mass percentage of nano carbon dioxide and nano Silica is mixed, and water is added with a volume of 4 times. Under the action of ultrasonic vibration, the conditions of ultrasonic vibration here are: the ultrasonic frequency is 30kHz, and the ultrasonic power is 220W to form a uniform mixture A; the mixture A is added dropwise into the mixture of tetraethyl orthosilicate, alcohol and coupling agent, and fully stirred evenly to obtain composite modified nano-sol.

[0046] Wherein, in this embodiment, the visible light-activat...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com