Preparation method of dried porphyridium powder

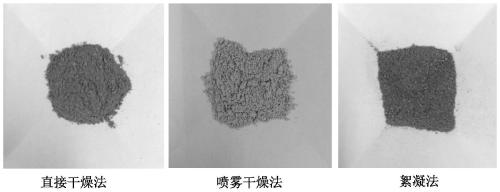

A technology of Porphyridium algae dry algae powder and Porphyridium algae liquid, applied in the field of marine microorganisms, can solve the problems of uneven combination of algae cells and flocculants, easy agglomeration, low efficiency, etc., to solve the problem of uneven combination, The effect of bright colors, reducing centrifugal force and centrifuging time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

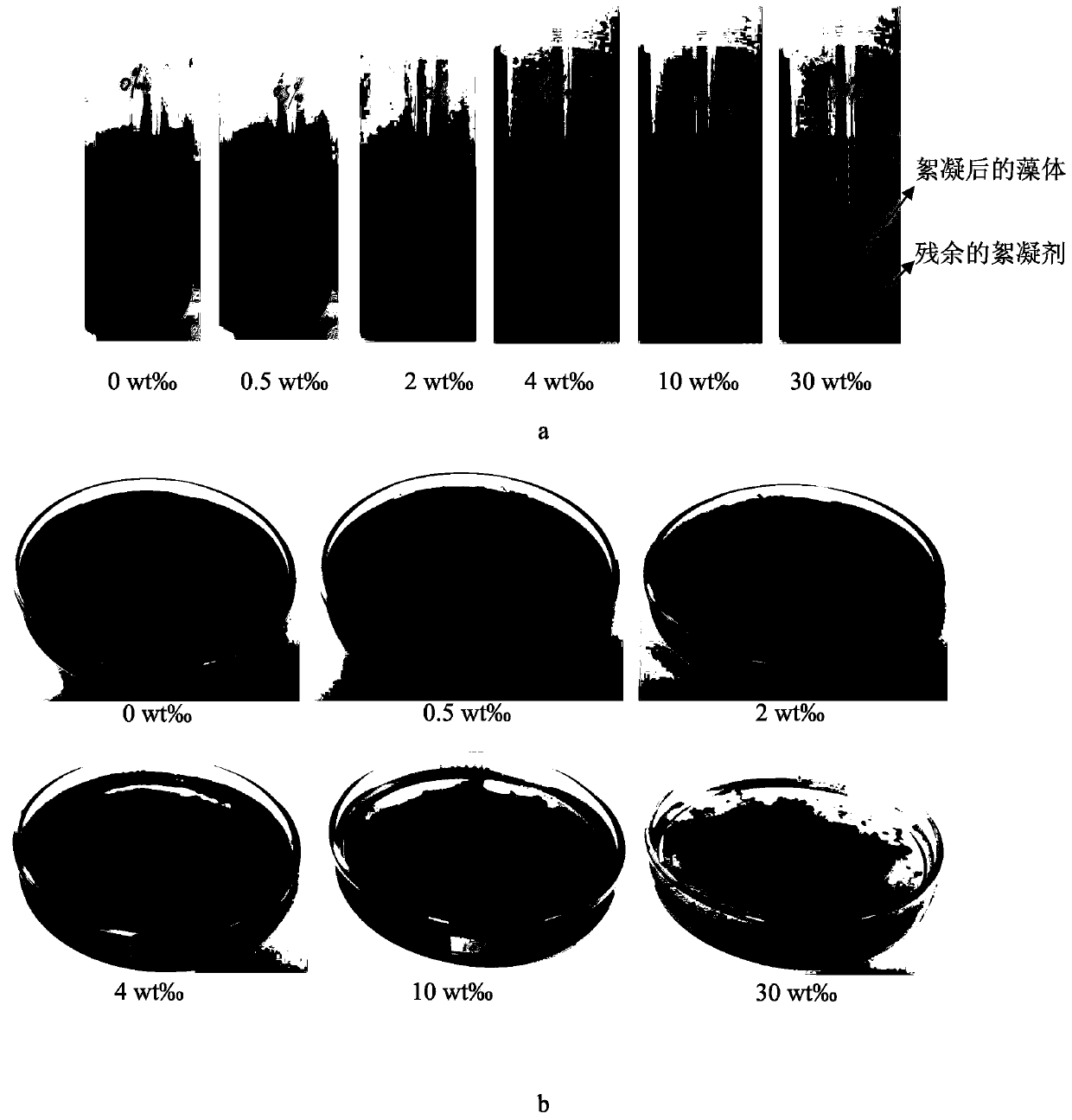

[0027] (1) Mix the flocculant cationic etherified starch with water, heat at 50°C for 30 minutes, and then cool to room temperature to obtain a flocculant solution with a concentration of 2wt‰;

[0028] (2) The above-mentioned flocculant solution and Porphyridium purpureum CoE1 (in the stable growth phase) are slowly stirred and mixed at room temperature at a volume ratio of 0.5:1 at a speed of 20 rpm (stirring speed is such that no naked eyes will be produced in the liquid). Visible bubbles), so that the cells of Porphyridium coccus and the flocculant are fully flocculated, and then left to stand until solid-liquid separation;

[0029] (3) discard the supernatant of the material obtained in step (2), then remove the remaining moisture by centrifuging at 2000rpm for 10min to obtain a precipitate;

[0030] (4) Mix the above precipitate with water, centrifuge at 2000rpm for 10min and wash 3 times to wash away excess flocculant and unflocculated cells, and collect the algae sludg...

Embodiment 2

[0036] (1) Mix the flocculant cationic etherified starch with water, heat at 70°C for 30 minutes, and then cool to room temperature to obtain a flocculant solution with a concentration of 4wt‰;

[0037] (2) The above-mentioned flocculant solution and Porphyridium purpureum CoE1 (in the stable growth phase) are slowly stirred and mixed at a volume ratio of 1:1 at a speed of 30 rpm (the stirring speed is such that no visible bubbles will be produced in the liquid. ) to fully flocculate the cells of Porphyridium algae and the flocculant, and then leave it to solid-liquid separation;

[0038] (3) Discard the supernatant of the material obtained in step (2), then remove the remaining moisture by centrifuging at 4000rpm for 5min to obtain a precipitate;

[0039] (4) Mix the above precipitate with water, centrifuge at 4000rpm for 5min and wash 3 times to wash away excess flocculant and unflocculated cells, and collect the algae sludge;

[0040] (5) The above-mentioned algae mud is v...

Embodiment 3

[0045](1) Mix the flocculant cationic etherified starch with water, heat at 100°C for 30 minutes, and then cool to room temperature to obtain a flocculant solution with a concentration of 10wt‰;

[0046] (2) The above-mentioned flocculant solution and Porphyridium purpureum CoE1 (in the stable growth phase) are slowly stirred and mixed at a volume ratio of 2:1 at a speed of 40 rpm (the stirring speed is such that no visible bubbles will be produced in the liquid. ) to fully flocculate the cells of Porphyridium algae and the flocculant, and then leave it to solid-liquid separation;

[0047] (3) Discard the supernatant of the material obtained in step (2), then remove the remaining moisture by centrifuging at 8000rpm for 1min to obtain a precipitate;

[0048] (4) Mix the above precipitate with water, centrifuge at 8000rpm for 1min and wash 3 times to wash away excess flocculant and unflocculated cells, and collect the algae sludge;

[0049] (5) The above-mentioned algae mud is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com