Double-wall hollow winding pipe and preparation method thereof

A winding tube, hollow technology, applied in the direction of tubes, rigid tubes, mechanical equipment, etc., can solve the problems of limitation and singleness, and achieve the effect of blocking damage, delaying the aging speed, and protecting the color.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

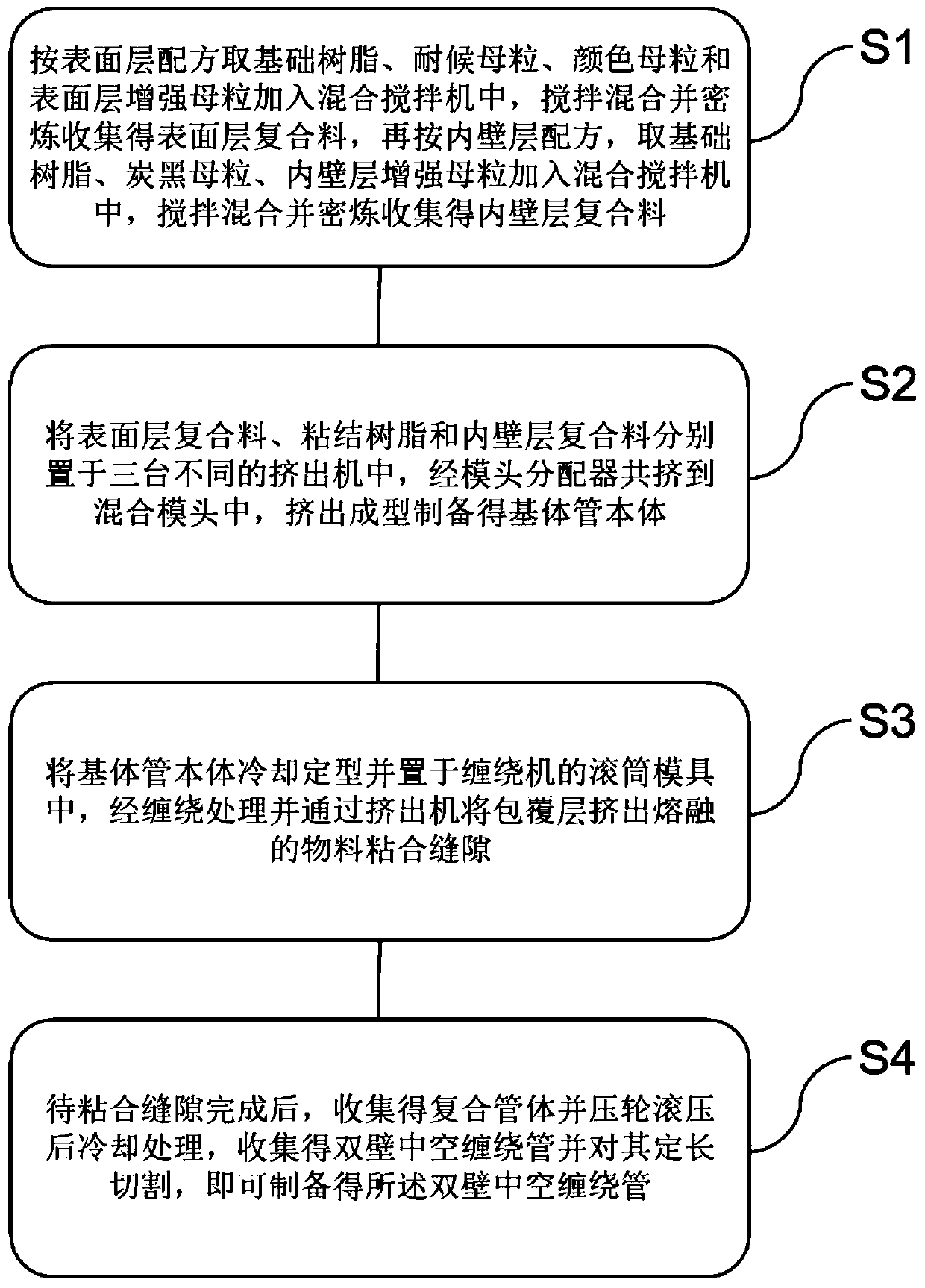

[0049] The preparation method of the double-walled hollow winding tube 100 according to the embodiment of the present invention, such as figure 1 As shown, it includes the following steps: S1. According to the formula of surface layer 11, take the base resin, weather-resistant masterbatch, color masterbatch and surface layer reinforcement masterbatch and add them to the mixing mixer, stir and mix and banbury to collect the surface layer compound, and then press For the formula of the inner wall layer 13, take the base resin, carbon black masterbatch, and inner wall layer reinforced masterbatch and add them to the mixing mixer, stir and mix and banbury to collect the inner wall layer compound material; S2, combine the surface layer compound material, bonding resin and inner wall layer The layered composite materials are respectively placed in three different extruders, co-extruded into the mixing die through the die distributor, and extruded to prepare the base pipe body 10; S3,...

Embodiment 1

[0053] (1) Determine the formula of the surface layer 11 of the double-wall hollow wound pipe 100 and prepare the surface layer mixture:

[0054] HDPE resin: 100 parts;

[0055] Weather-resistant masterbatch: 3 parts;

[0056] Color masterbatch: 1 part;

[0057] The surface layer 11 of the double-walled hollow winding pipe 100 is prepared according to the above formula, wherein the weather resistance additive is prepared by mixing hindered amine light stabilizer, ultraviolet absorber, composite antioxidant, dispersant and coupling agent, and then PE resin For matrix resin, according to the added mass of 35%, weather-resistant additives are added to matrix resin, and mixed to prepare weather-resistant masterbatch.

[0058] A color masterbatch is prepared by mixing PE resin, rutile titanium dioxide, a dispersant and a coupling agent, and the addition amount of the rutile titanium dioxide is controlled at 60% to prepare a color masterbatch.

[0059] (2) Determine the formula o...

Embodiment 2

[0068] (1) Determine the formula of the surface layer 11 of the double-wall hollow wound pipe 100 and prepare the surface layer mixture:

[0069] PP resin: 100 parts;

[0070] Weather-resistant masterbatch: 3 parts;

[0071] Color masterbatch: 1 part;

[0072] The PP resin is a resin prepared by mixing a homopolymer PP resin and a copolymer PP resin at a mass ratio of 1:1.

[0073] Prepare the surface layer 11 of the double-walled hollow winding tube 100 according to the above formula, wherein the weather resistance additive is prepared by mixing hindered amine light stabilizer, ultraviolet absorber, composite antioxidant, dispersant and coupling agent, and then PP resin For matrix resin, according to the added mass of 35%, weather-resistant additives are added to matrix resin, and mixed to prepare weather-resistant masterbatch.

[0074] A color masterbatch is prepared by mixing PE resin, rutile titanium dioxide, a dispersant and a coupling agent, and the addition amount of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com