Petroleum heat extraction multiple thermal fluid generation system adopting petroleum coke as fuel

A multi-component thermal fluid and generation system technology, which is applied in the direction of mining fluid, burning with multiple fuels, burning with block fuel and liquid fuel, etc., can solve the problems of not giving the structure of the burner, and the combustion efficiency is yet to be verified. , to achieve the effect of improving the atomization effect, stabilizing combustion, and ensuring stable combustion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

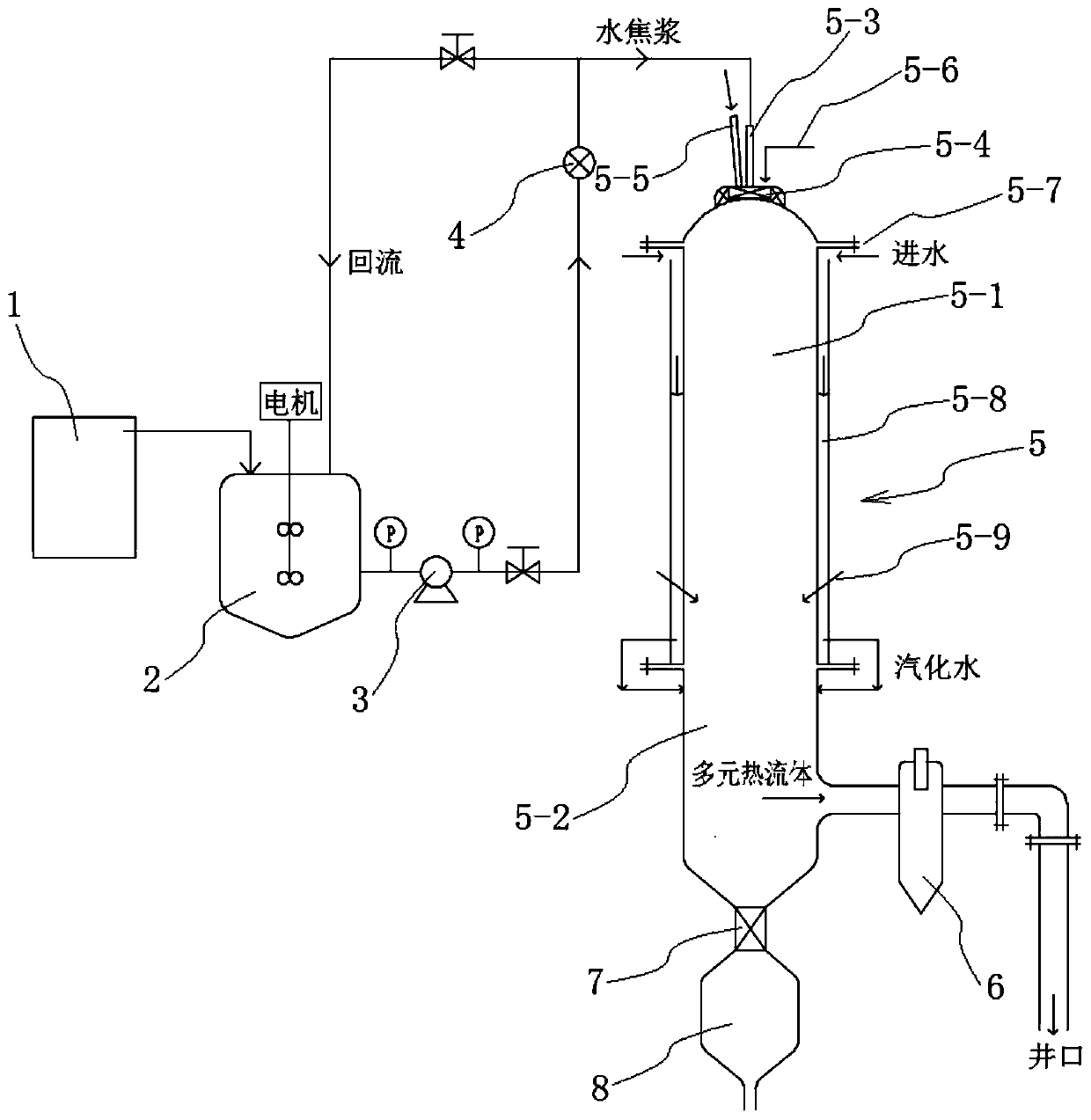

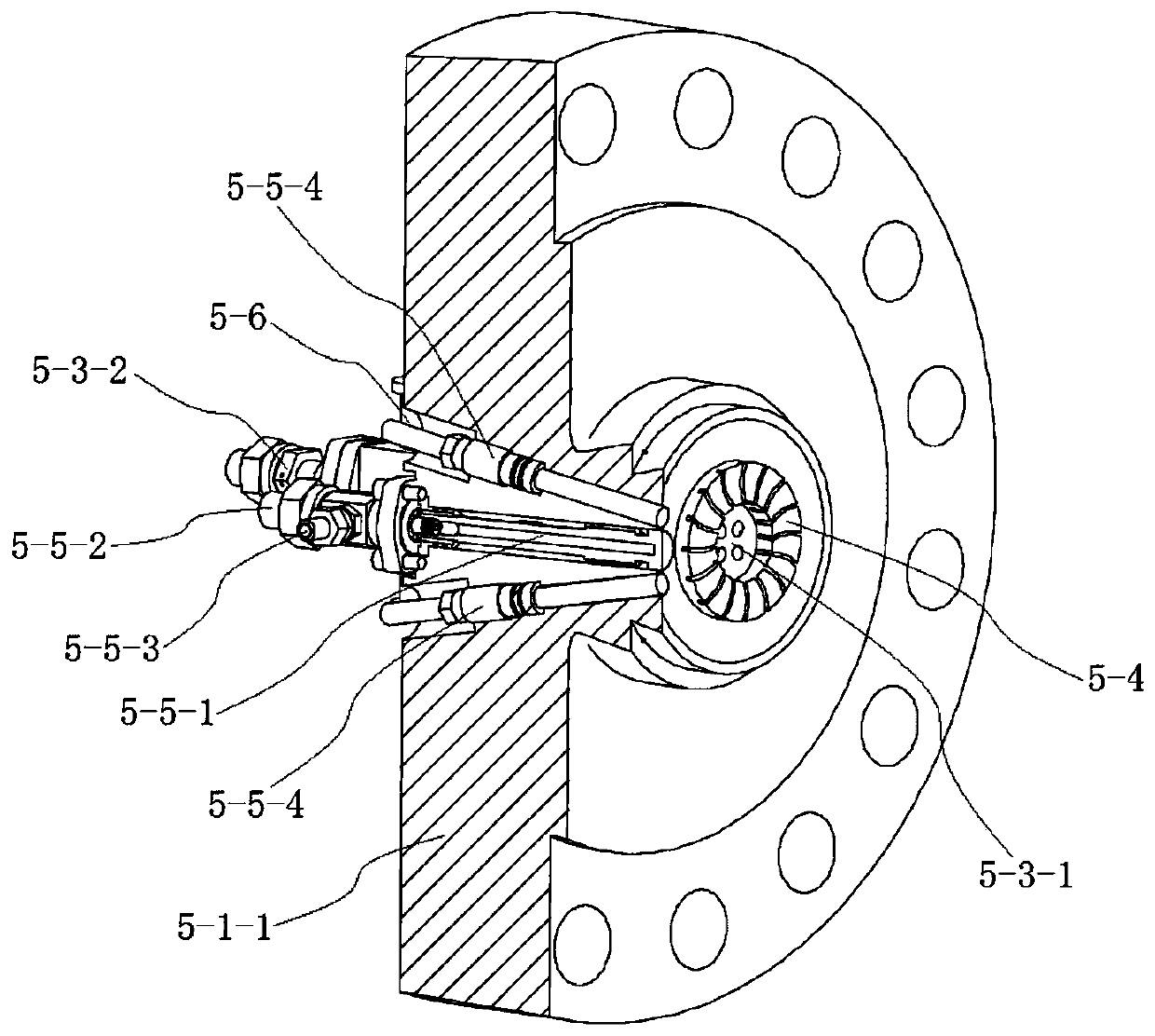

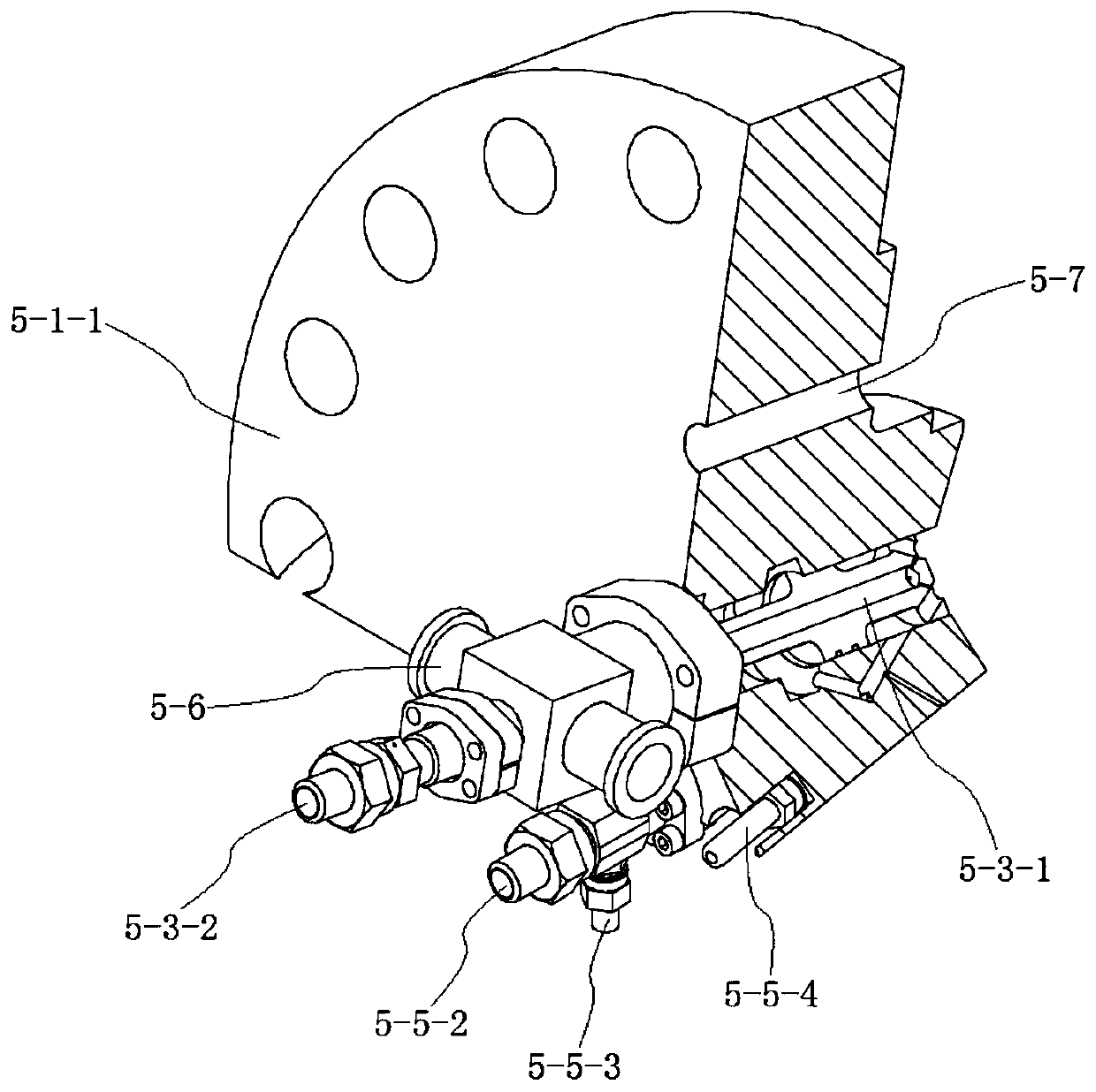

[0052] like Figure 1 to Figure 7As shown, a multi-component thermal fluid generating system for petroleum thermal recovery using petroleum coke as fuel in this embodiment includes a pulping device 1, a stirring tank 2, a high-pressure pump 3, a burner 5, a high-temperature separator 6 and a slag storage tank 8. Pulping device 1 is used to make petroleum coke into water coke slurry. Existing petroleum coke pulping equipment can be used. Water coke slurry is usually composed of petroleum coke powder, water and additives. In order to improve the combustion of water coke slurry Performance, in the present embodiment, the mass percentage component of the water coke slurry prepared by pulping device 1 is: petroleum coke (powder): 75%; Water: 22%; Fixing agent: 3%; The water coke slurry after configuration The fixed viscosity concentration reaches 80wt%, which improves the stability of the coke slurry, makes the coke slurry have good slurrying properties, facilitates the atomization...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com