Ammonia gas sensor, and preparation method and application method thereof

An ammonia sensor and ammonia technology, applied in the field of ammonia sensors, can solve the problems that cannot be put into mass production and engineering application, and achieve the effects of high sensitivity and detection limit, fast response speed, and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The specific implementation manners of the present invention will be further described below in conjunction with the drawings and examples. The following examples are only used to illustrate the technical solution of the present invention more clearly, but not to limit the protection scope of the present invention.

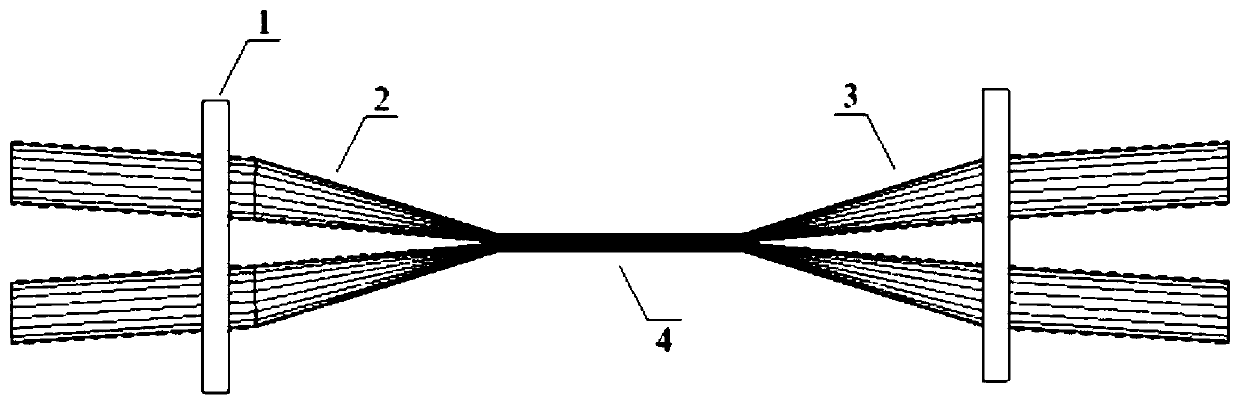

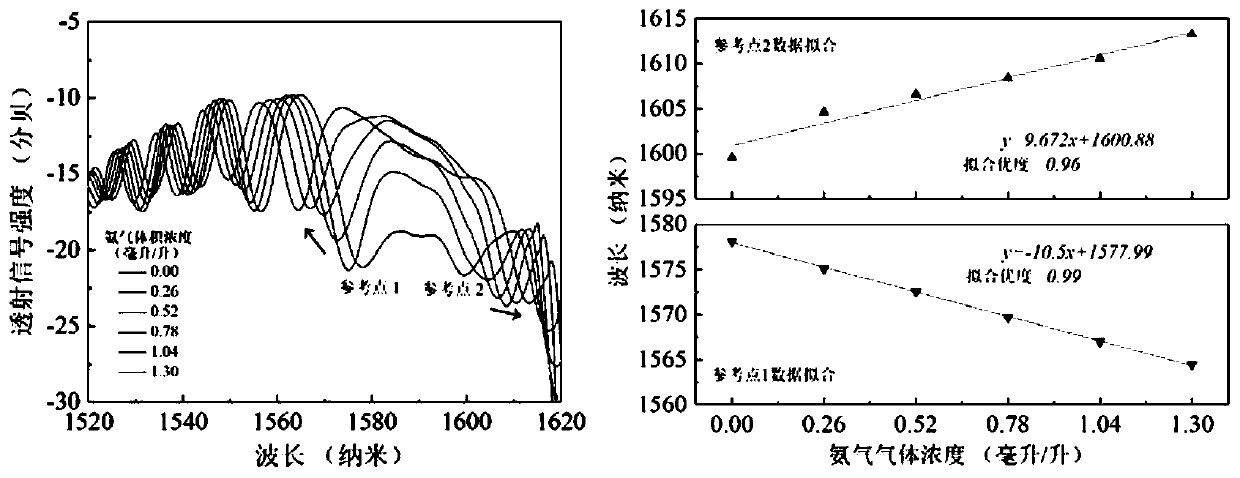

[0026] The invention provides an ammonia sensor, which is based on a tapered micro-nano optical fiber coupler structure, and is prepared through the following steps:

[0027] 1) Twist two sections of single-mode optical fiber together and select 25-30mm in the middle to peel off the coating layer. After cleaning and wiping with alcohol, fix the optical fiber in the fixture of the tapered platform, and run the tapered program after heating until softened;

[0028] 2) Adjust the execution details of the taper program through the data information fed back by the spectrometer. After the coupler is manufactured, it is fixed on the base platform with low refracti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com